A kind of halogen-free flame retardant resin and preparation method thereof

A flame retardant resin and flame retardant technology, applied in the field of halogen-free flame retardant polymers, can solve the problems of personnel injury, ash formation, secondary damage, etc., and achieve enhanced mechanical strength, improved flame retardant performance, and good mechanical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

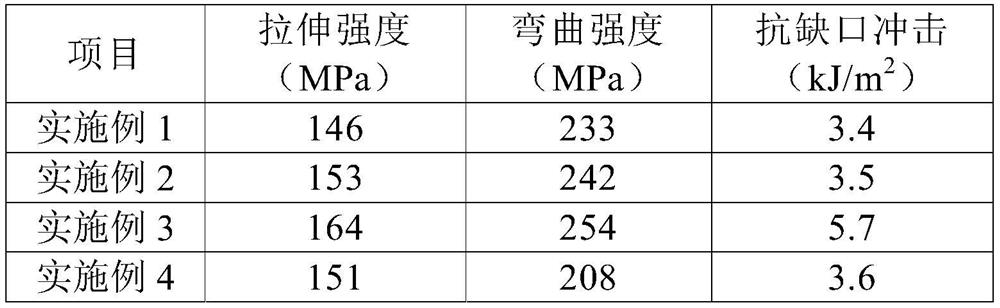

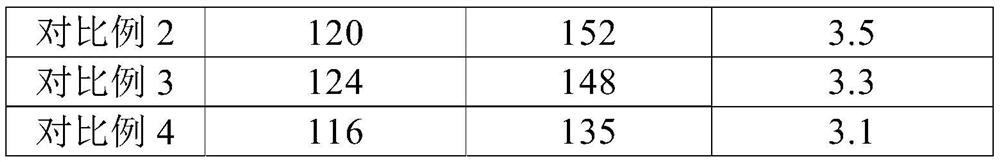

Examples

Embodiment 1

[0036] The halogen-free flame retardant resin of this embodiment includes the following components in parts by weight:

[0037] Polyamide PA56: 100 parts

[0038] Aluminum hypophosphite: 20 parts

[0039] Fiberglass: 33 parts

[0040] WAX-E: 0.3 parts

[0041] WAX-C: 0.6 parts

[0042] Antioxidant 1010: 0.4 parts

[0043] The preparation method of the halogen-free flame retardant resin of the present embodiment comprises the following steps:

[0044] 1) prepare materials according to the above ratio;

[0045] 2) Mix PA56, aluminum hypophosphite, WAX-E, WAX-C and antioxidant 1010 to obtain a premix;

[0046] 3) Use a twin-screw extruder to blend and melt the premix, and while blending and melting, use a feeder to forcibly feed the glass fibers into the premix, and after 5 minutes, extrude through a twin-screw The machine extruded strands, cooled the strands to below the melting point of PA56 with water as the cooling medium, and cut and granulated to obtain the halogen-f...

Embodiment 2

[0054] The halogen-free flame retardant resin of this embodiment includes the following components in parts by weight:

[0055] Polyamide PA56: 100 parts

[0056] Aluminum hypophosphite: 15 parts

[0057] Fiberglass: 33 parts

[0058] WAX-E: 0.3 parts

[0059] WAX-C: 0.6 parts

[0060] Antioxidant 1098: 0.2 parts

[0061] The preparation method of the halogen-free flame retardant resin of the present embodiment comprises the following steps:

[0062] 1) prepare materials according to the above ratio;

[0063] 2) Mix PA56, aluminum hypophosphite, WAX-E, WAX-C and antioxidant 1098 to obtain a premix;

[0064] 3) Use a twin-screw extruder to blend and melt the premix, and while blending and melting, use a feeder to forcibly feed the glass fibers into the premix, and after 5 minutes, extrude through a twin-screw The machine extruded strands, cooled the strands to below the melting point of PA56 with water as the cooling medium, and cut and granulated to obtain the halogen-f...

Embodiment 3

[0072] The halogen-free flame retardant resin of this embodiment includes the following components in parts by weight:

[0073] Polyamide PA56: 100 parts

[0074] Aluminum hypophosphite: 10 parts

[0075] Fiberglass: 33 parts

[0076] WAX-E: 0.3 parts

[0077] WAX-C: 0.6 parts

[0078] Antioxidant 1098: 0.2 parts

[0079] The preparation method of the halogen-free flame retardant resin of the present embodiment comprises the following steps:

[0080] 1) prepare materials according to the above ratio;

[0081] 2) Mix PA56, aluminum hypophosphite, WAX-E, WAX-C and antioxidant 1098 to obtain a premix;

[0082] 3) Use a twin-screw extruder to blend and melt the premix, and while blending and melting, use a feeder to forcibly feed the glass fibers into the premix, and after 5 minutes, extrude through a twin-screw The machine extruded strands, cooled the strands to below the melting point of PA56 with water as the cooling medium, and cut and granulated to obtain the halogen-f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com