A carbon nanotube modified polyolefin double resistance material and its preparation method and application

A carbon nanotube modification and carbon nanotube technology, which is applied in the field of flame retardant and antistatic polyolefin composite materials, can solve the problems of a large amount of flame retardant, brittle pipes, poor pressure resistance, etc., and can promote flame retardancy. agent, improve the service life, and avoid the effect of tube brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

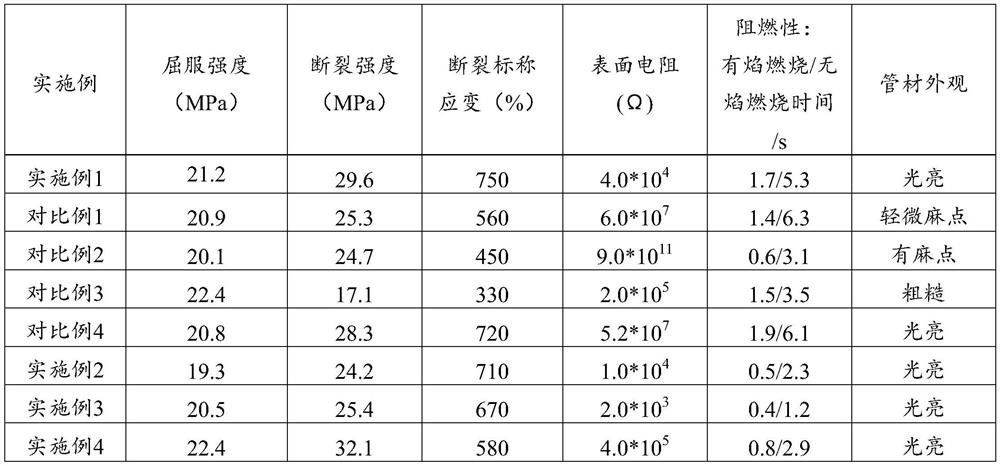

Examples

Embodiment 1

[0040] The preparation of the polyolefin elastomer of maleic anhydride, polysiloxane bifunctional grafting: the polyethylene-octene copolymer (8200, Dow Chemical) of 78.42% by weight, the maleic anhydride of 1.5%, 20% After the polysiloxane and 0.08% organic peroxide dicumyl peroxide are mixed evenly, the bifunctional grafting is carried out at 200-210°C by a twin-screw extruder to obtain maleic anhydride, polysiloxane grafted branched polyolefin elastomer (POE-g-MAH / Si).

[0041] Surface treatment of S1 conductive agent:

[0042] Multi-walled carbon nanotubes (NC7000, Belgium Nanocyl) 3%, superconducting carbon black (Ketjen Black ECP600JD) 2.5%, Add 1.5% of dispersant (6879, Evonik Degussa) into the high mixer, mix at 500rpm for 30min, and discharge for later use.

[0043] Preparation of Conductive Agent / Polyethylene Composite Powder by S2 Rotary Shear Dispersion

[0044] Mix the conductive agent mixture treated with S1 and 50% grade 100 polyethylene pipe material (100S,...

Embodiment 2

[0083] The preparation of the polyolefin elastomer of maleic anhydride, polysiloxane bifunctional graft: the polyethylene-octene copolymer (LC170 of LG chemistry) of weight ratio 50%, 37.95% polyethylene-butene copolymer ( LC565, LG Chemical), 2% of maleic anhydride, 10% of polysiloxane, 0.05% of organic peroxide di-tert-butyl peroxide mixed evenly, using a twin-screw extruder at 230 ℃ for double Functional grafting to obtain maleic anhydride, polysiloxane grafted polyolefin elastomer (POE-g-MAH / Si).

[0084] Surface treatment of S1 conductive agent:

[0085] Single-walled carbon nanotubes (TNSR, Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences) 2%, chopped carbon fibers (length 3mm) 4%, Add 2% of DS 360 dispersant (Yantai Wanhua) into the high mixer, mix at 800rpm for 20min, and discharge for later use.

[0086] Preparation of Conductive Agent / Polyethylene Composite Powder by S2 Rotary Shear Dispersion

[0087] Mix the conductive agent mixture treated with...

Embodiment 3

[0093] The preparation of the polyolefin elastomer of maleic anhydride, polysiloxane bifunctional graft: the polyethylene-vinyl acetate copolymer (3170, Du Pont) of weight ratio 83.98%, 1% maleic anhydride, 15% After polysiloxane and 0.02% organic peroxide 2,5-dimethyl-2,5-di-tert-butylperoxyhexane are mixed uniformly, bifunctional grafting is carried out at 170°C using a twin-screw extruder , to obtain maleic anhydride, polysiloxane grafted polyolefin elastomer (EVA-g-MAH / Si).

[0094] Surface treatment of S1 conductive agent:

[0095] Multi-walled carbon nanotubes (GT210, Shandong Dazhan Nano Material Co., Ltd.) 5%, carbon fiber powder (50 orders) 0.5%, SOLPLUS TM Add 0.8% of K240 dispersant (Lubrizol) into the high mixer, mix at 600rpm for 40min, and discharge for later use.

[0096] Preparation of Conductive Agent / Polyethylene Composite Powder by S2 Rotary Shear Dispersion

[0097] Mix the conductive agent mixture treated with S1 and 40% heat-resistant polyethylene pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com