Battery case packing production line

A technology of shell packing and production line, which is applied in the directions of packaging, packing protection, transportation and packaging, etc. It can solve the problems of low automation, high cost, and low packing efficiency, and achieve high automation, low cost, and packing efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The present invention will be further described below with reference to the accompanying drawings.

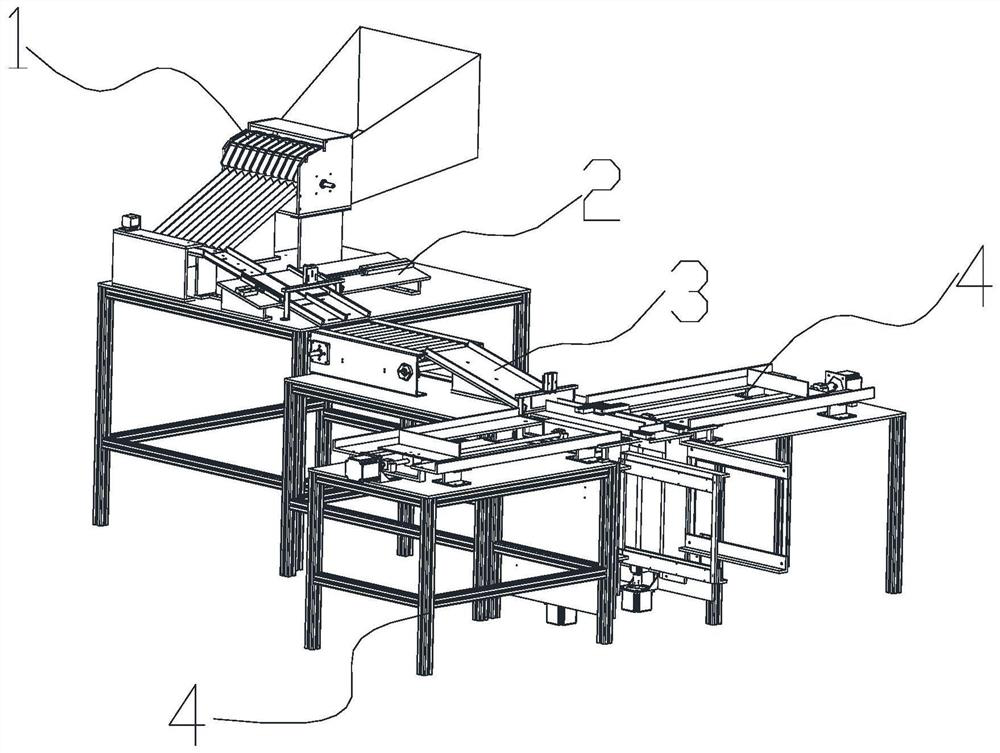

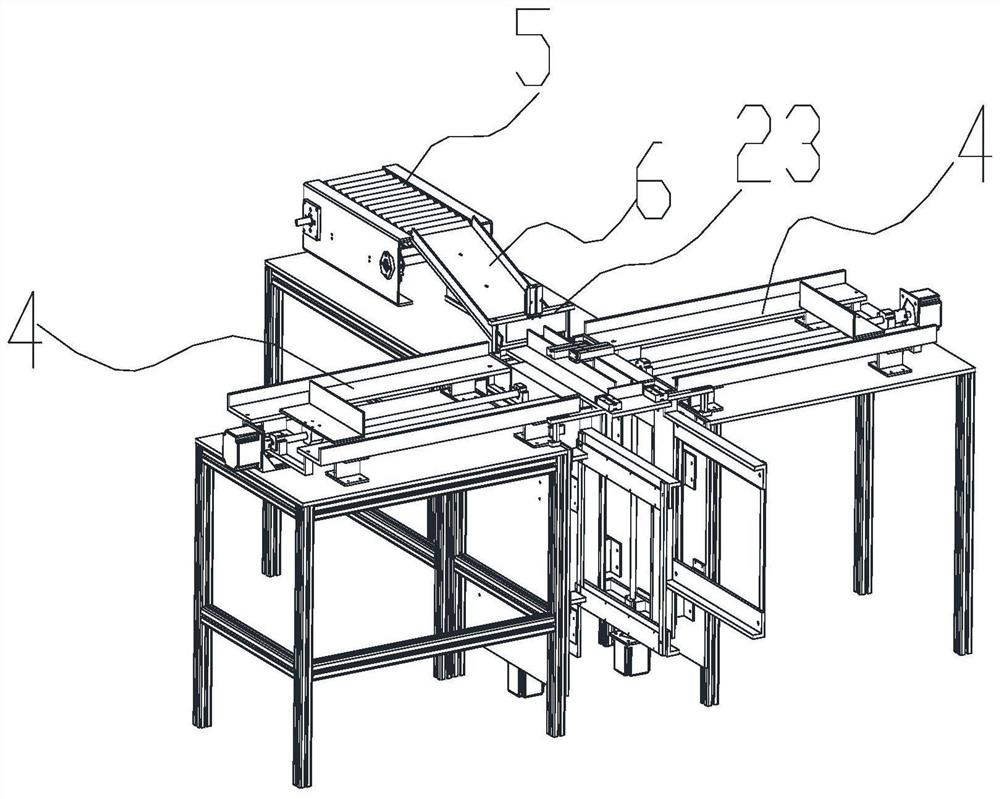

[0035]Battery shell packing production line, including a discharge device, a partial device, a delivery device, and a packing device. The discharge device, a partial device, a conveying device, and a packing device are sequentially set.

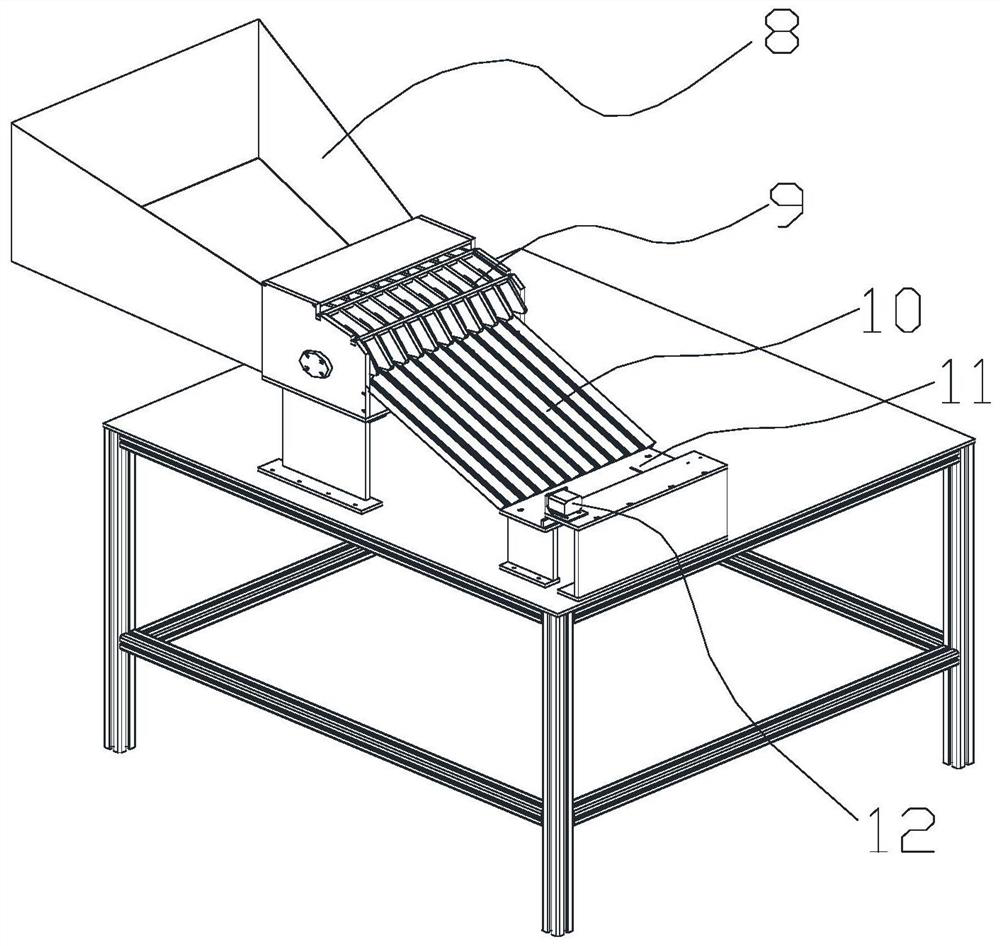

[0036]The discharge device is used to discharge the battery shell in the hopper. The discharge device includes a flip mechanism, a suction mechanism, a downlink passage, and a rowing platform. The flip mechanism includes power components, drums, and multiple flip channels. The power component is a stepper motor, a stepping motor, and a drum. The roller rotation is mounted at the exit of the hopper, and the flip passage is disposed above the drum, and the plurality of flip channels are set in parallel. The suction mechanism is disposed on the drum, set the downstream of the drum, and set the row platform at the outlet of the lower channel.

[0037]The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com