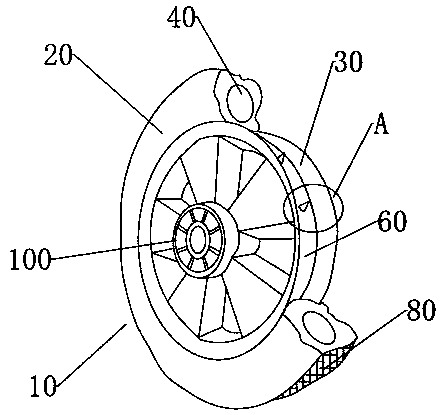

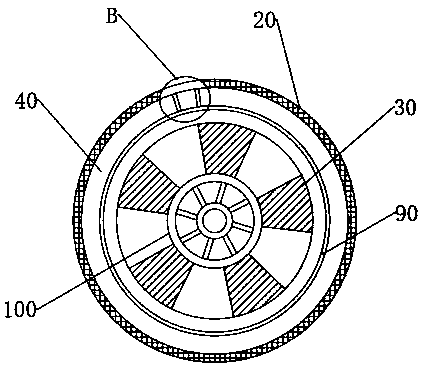

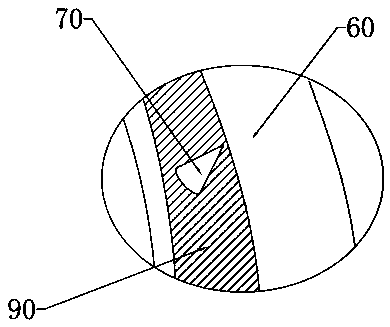

Rubber wheel for trolley and production process thereof

A production process and rubber wheel technology, applied in the direction of wheels, wheel testing, wheels made of non-metallic materials, etc., can solve the problems of easy falling off, wheel hub damage, etc., and achieve the effect of not easy to break, not easy to damage, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] S1, first prepare the material of the rubber outer ring 20, mainly select raw rubber and vulcanizing agent, first bake the raw rubber at a temperature of 60°C to soften, then cut the rubber into small pieces, and then screen the vulcanizing agent.

[0055] S2, the materials are placed in the rubber mixing machine in the order of raw rubber, accelerator, high wear-resistant furnace carbon black, engine oil and vulcanizing agent (sulfur). The roller temperature of the rubber mixing machine is controlled at 40°C, and then the Stir to fully stir the materials so that the above ingredients can be evenly distributed in the raw rubber.

[0056] S3, put the material prepared in S2 into an automatic rubber vulcanizer, and vulcanize at a temperature of 145° C. for 15 minutes to convert plastic rubber into elastic rubber.

[0057] S4, press the elastic rubber material into the rubber outer ring 20 mold, cool down, open the mold, and take out the rubber outer ring 20 .

[0058] S5...

Embodiment 2

[0063] S1, first prepare the material of the rubber outer ring 20, mainly select raw rubber and vulcanizing agent, first bake the raw rubber at a temperature of 60°C to soften, then cut the rubber into small pieces, and then screen the vulcanizing agent.

[0064] S2, the materials are placed in the rubber mixing machine in the order of raw rubber, accelerator, high wear-resistant furnace carbon black, engine oil and vulcanizing agent (sulfur). The roller temperature of the rubber mixing machine is controlled at 40°C, and then the Stir to fully stir the materials so that the above ingredients can be evenly distributed in the raw rubber.

[0065] S3, put the material prepared in S2 into an automatic rubber vulcanizer, and vulcanize at a temperature of 155° C. for 20 minutes to convert plastic rubber into elastic rubber.

[0066] S4, press the elastic rubber material into the rubber outer ring 20 mold, cool down, open the mold, and take out the rubber outer ring 20 .

[0067] S5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com