Household glove and manufacturing method thereof

A production method and technology of household gloves, which are applied to household components, household appliances, and other household appliances, can solve problems such as uneven thickness of gloves, high chronic toxicity hazards, and increased costs, so as to avoid repeated dipping and repeated heating, and produce products Good uniformity and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

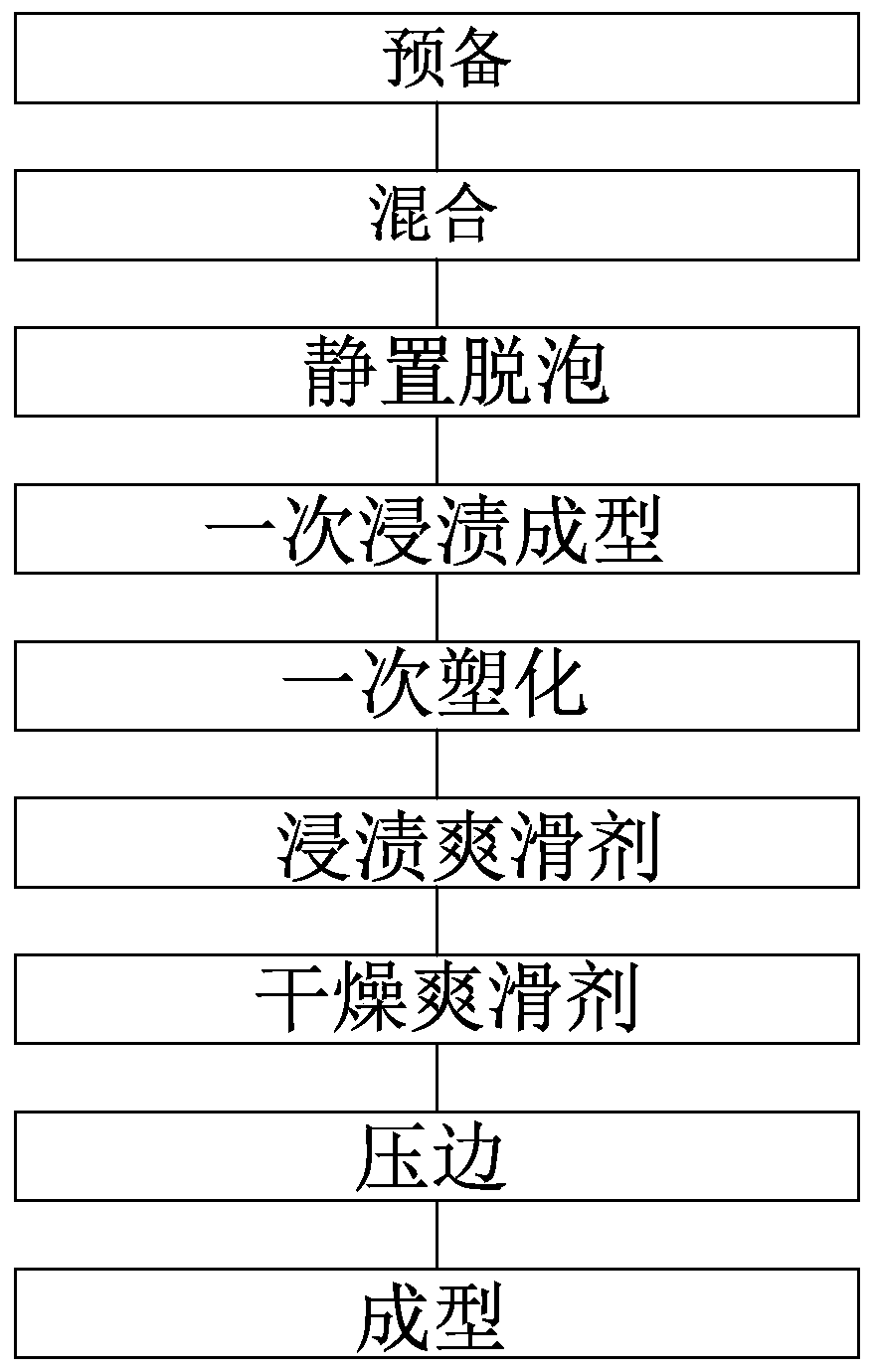

[0027] refer to figure 1 The embodiment of a household glove and its manufacturing method of the present invention will be further described.

[0028] A method for making household gloves, comprising the steps of: (1) preparing the following ingredients, and the content of each component is as follows: 100-120 parts of polyester plasticizer, 50-60 parts of DINP, 40-50 parts of DOTP , 5-10 parts of DOP, 200-300 parts of PVC paste resin, 12 parts of liquid calcium-zinc stabilizer, 15-20 parts of rheology modifier and 5-10 parts of viscosity reducer; PVC paste resin and plasticizer 1 : about 1, polyester plasticizers account for more than half of the plasticizers, the others are citrate plasticizers or DOTP or DINP, TXIB accounts for a small part,

[0029] (2) Mixing: Mix polyester plasticizer, DINP, DOTP, DOP and other plasticizers and stir, then add PVC paste resin, liquid calcium zinc stabilizer, rheology additive, 5-10 parts of viscosity reducer in sequence and adding the q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com