Equipment based on waterproof type premixed mortar

A ready-mixed mortar and waterproof technology, which is applied in the field of ready-mixed mortar, can solve the problems of uneven mixing and distribution of various mortar raw materials, difficulty in cracking, and affecting the processing quality of ready-mixed mortar, so as to ensure the fine crushing effect and improve uniformity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

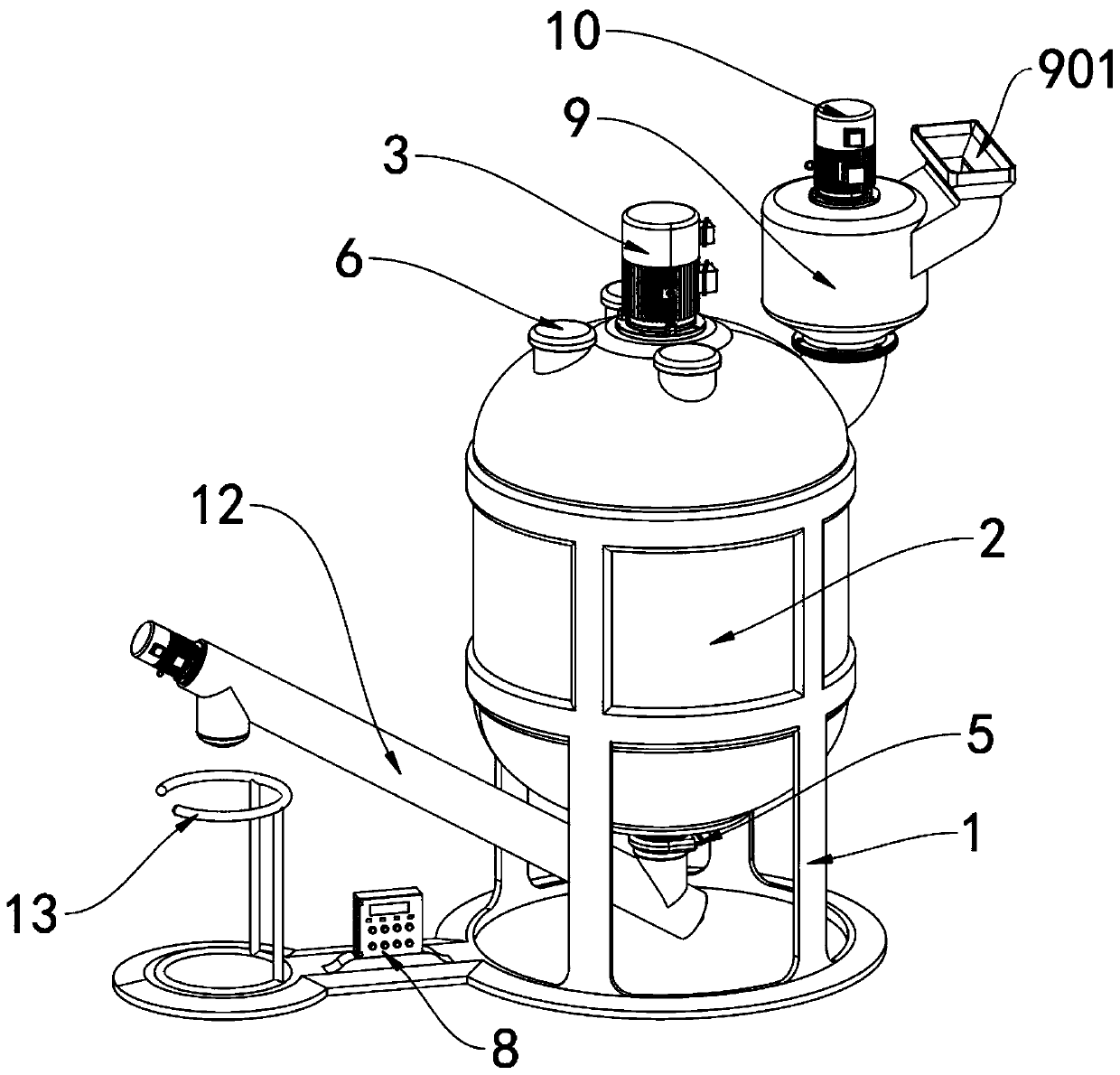

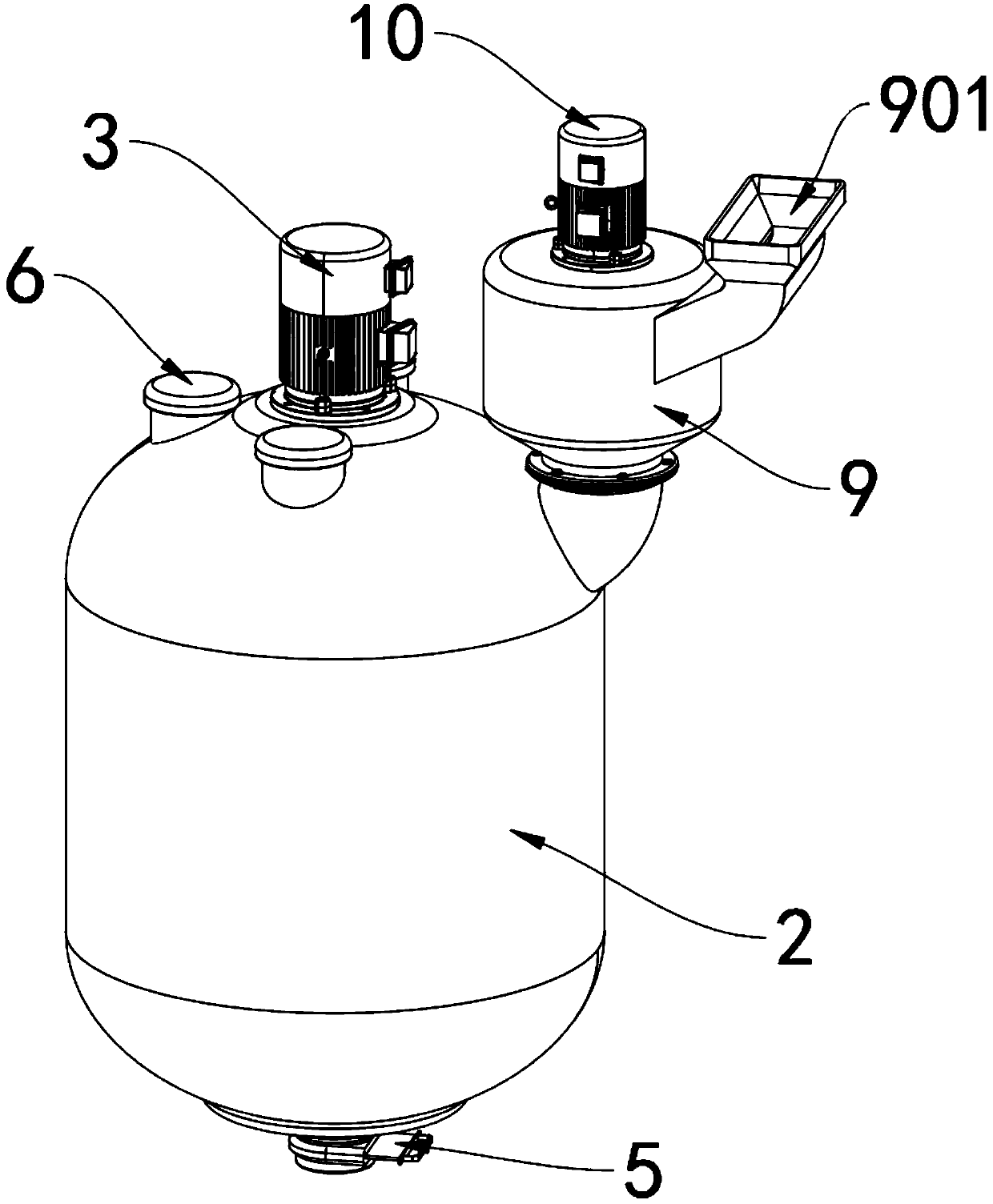

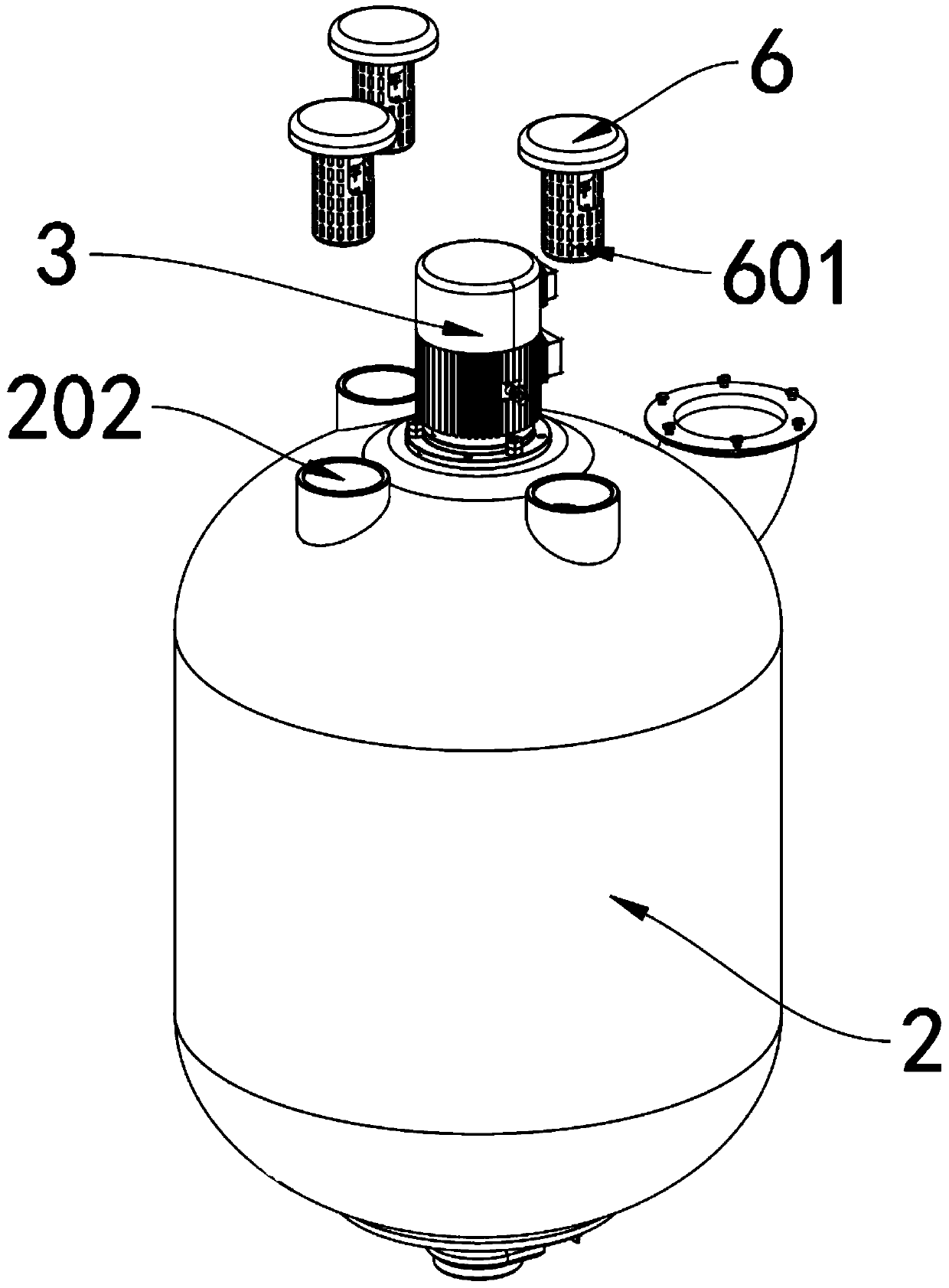

[0030] as attached figure 1 to attach Figure 9 Shown:

[0031]The invention provides an equipment based on waterproof ready-mixed mortar, which includes a ready-mixed mixing tank 2, a mixing motor 3, a screw conveying rod 4, a baffle 5, a moisture-proof sealing cover 6, a fine grinding cylinder 9, a grinding motor 10, a grinding Knife 11 and screw feeder 12; the interior of the ready-mixed mixing tank 2 is a hollow structure, and the ready-mixed mixing tank 2 is installed in the top of the support frame 1, and the top of the ready-mixed mixing tank 2 is surrounded by three assembly holes 202; The mixing motor 3 is installed on the top end surface of the ready-mixing mixing tank 2 through bolts, and the mixing motor 3 is electrically connected to the inside of the control electric box 8 through a power line; the screw conveying rod 4 is located inside the ready-mixing mixing tank 2, and the screw conveying rod 4 The bottom end is rotatably connected to the bottom of the read...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com