Method for grouping tobacco leaf raw materials in cigarette leaf group formula

A grouping method and technology of cigarette leaves, which are applied in the fields of tobacco, tobacco preparation, and manufacturing computing system, etc., can solve problems such as limitation, failure to achieve complementary coordination, reduction of richness and diversity, etc., and achieve strong operability and stable cigarettes. Product quality, the effect of improving the quality of cigarette products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

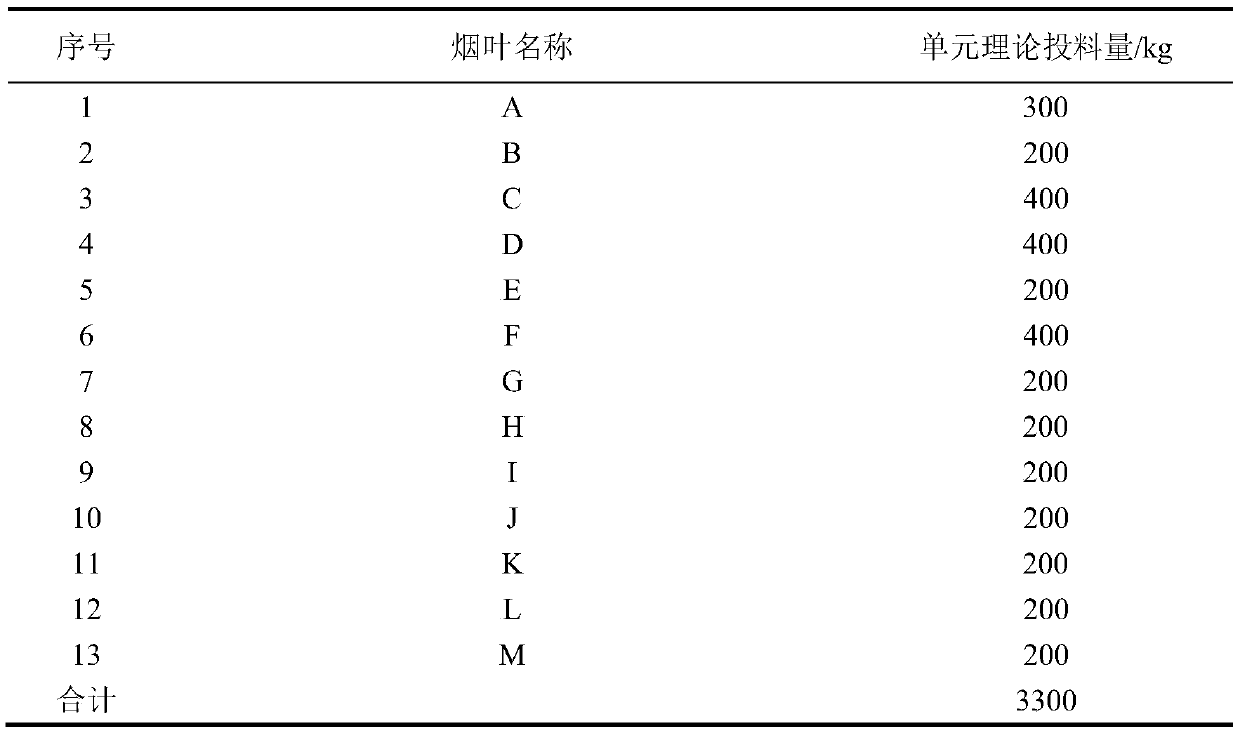

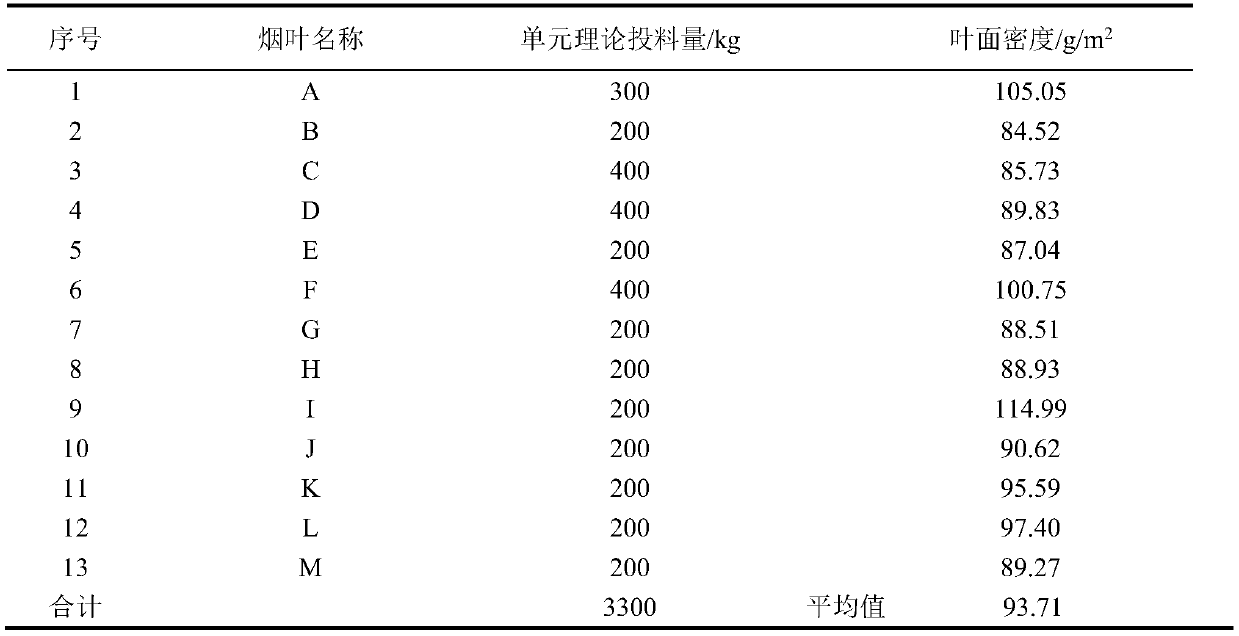

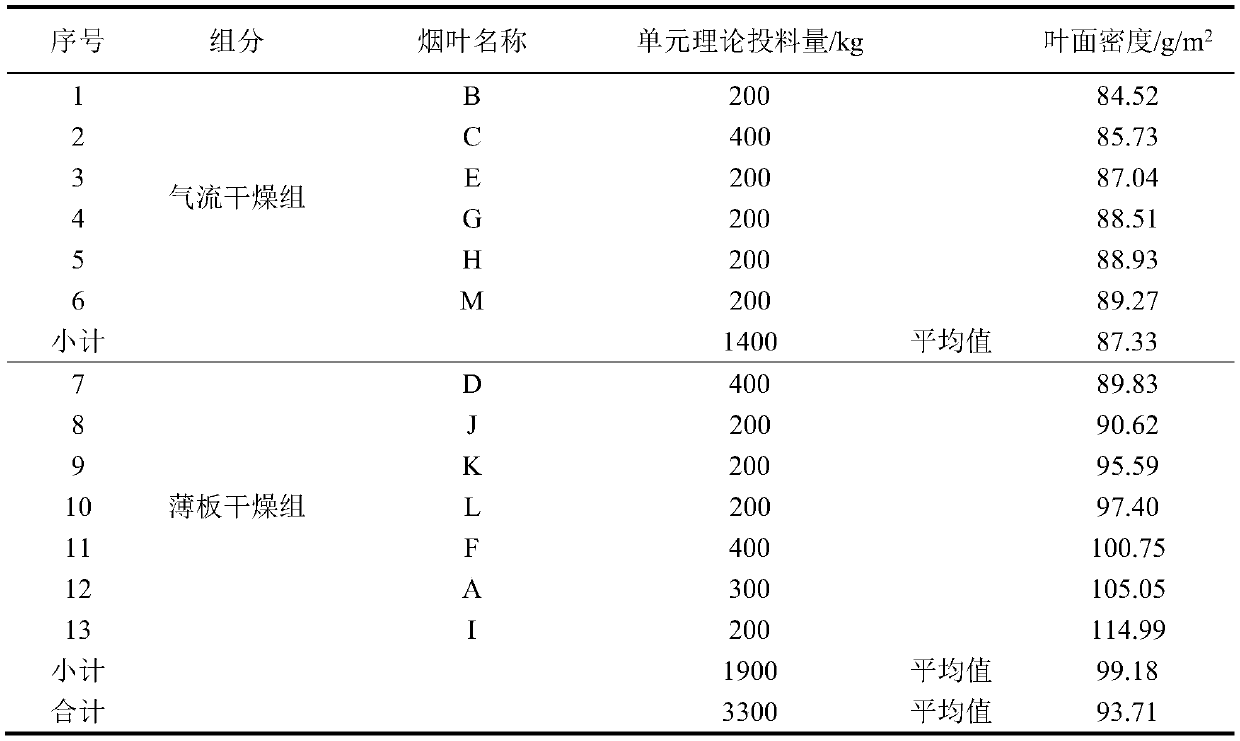

[0023] Step 1. For the new product of Huangshan brand A, the product formula designer designed the leaf group formula in the laboratory. The batch dosage of the leaf group formula is 3300kg. The leaf group formula is shown in Table 1.

[0024] Table 1 Huangshan A brand leaf group formula

[0025]

[0026] Since this product is a newly developed product, there are relatively few grades of tobacco leaves in the leaf group formula, and there are 13 grades of tobacco leaves. Tobacco leaf sampling In the raw material warehouse, three consecutive batches of tobacco leaves of each grade in the leaf group formula were sampled, and multi-point sampling was carried out from different cigarette bales for tobacco leaves of each grade.

[0027] Step 2. The tobacco leaves of all grades sampled are respectively rehydrated on the screen (40 mesh) placed on the constant temperature water bath. After resurfacing, the tobacco leaves use a leaf puncher to take 50 leaf discs, and wait until the...

Embodiment 2

[0038] Huangshan B brand product leaf group formula maintenance, the leaf group formula has a total of 31 grades of tobacco leaves, which are processed in groups, with a single batch of 12000kg. There are 14 grades in the thin plate drying group, and the feeding amount is 4200kg; there are 17 grades in the air drying group, and the feeding amount is 7800kg. The average leaf density is 92.53g / m 2 . Two grades of tobacco leaves need to be changed, tobacco leaves C and tobacco leaves D, respectively in the air-flow drying group and the thin-plate drying group. Tobacco leaf C and tobacco leaf D are fed 400kg and the leaf density is 87.52g / m3 respectively. 2 and 91.63g / m 2 . Tobacco leaf E and tobacco leaf F are proposed to replace these two grades of tobacco leaves, and the leaf density of tobacco leaf E and tobacco leaf F is 88.71g / m3 respectively 2 and 93.65g / m 2 , according to the leaf surface density grouping rules, use tobacco leaf E to replace tobacco leaf C, and use to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com