Construction device and construction method of self-adaptive post-tensioning prefabricated box girder

A construction device and post-tensioning technology, used in manufacturing tools, ceramic molding machines, etc., can solve problems such as cracking, beam end concrete stress concentration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

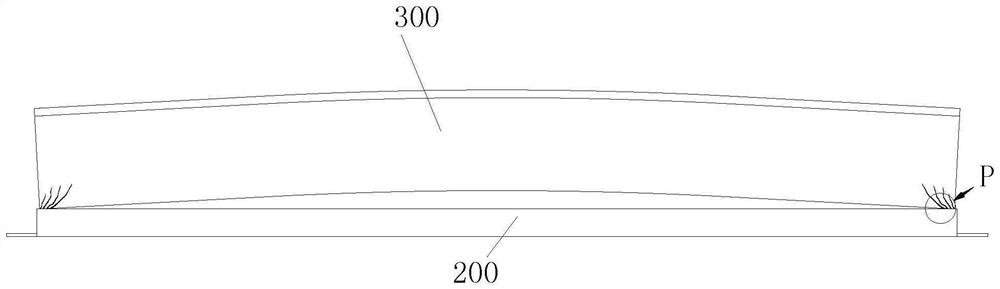

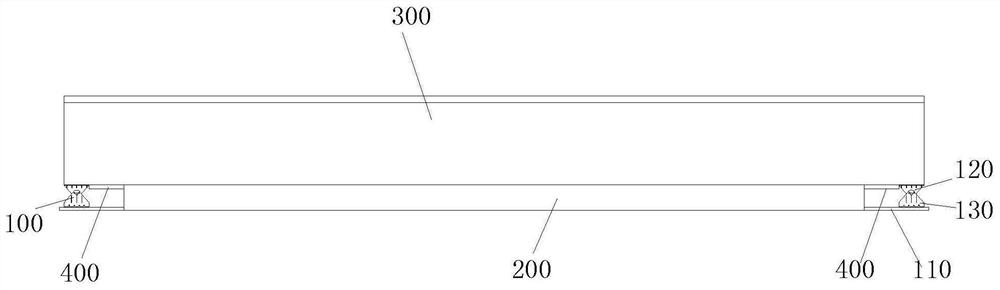

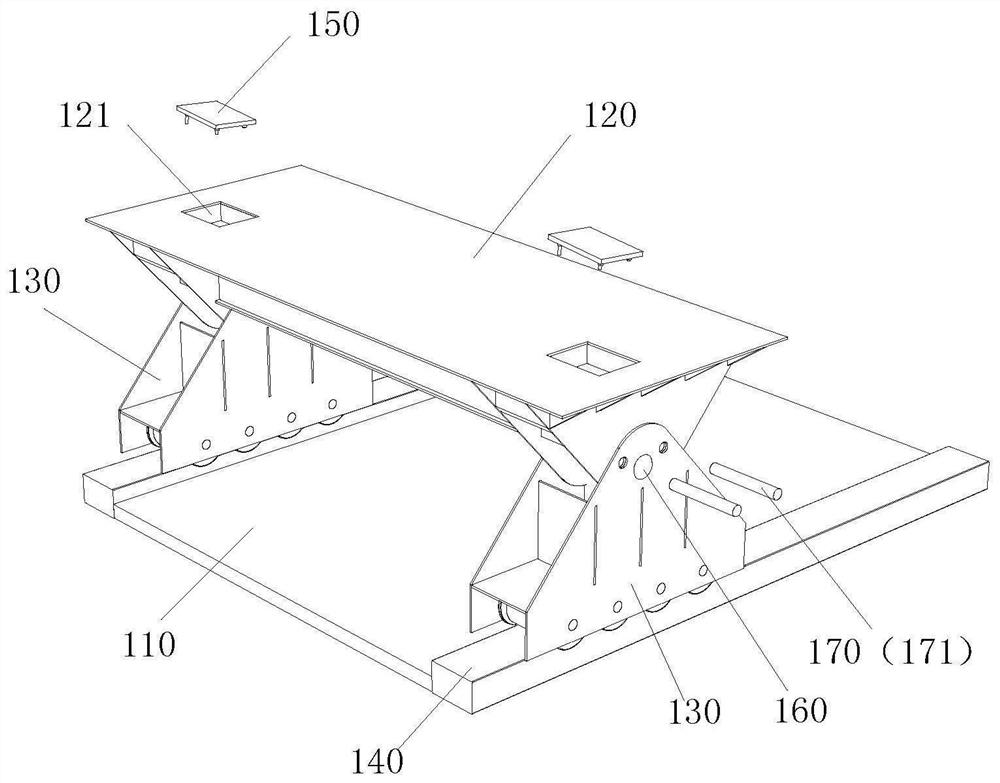

[0036] Such as Figure 2 to Figure 8 As shown, the construction device of the self-adaptive post-tensioning prefabricated box girder of the present embodiment includes a fixed base 200 and two adjustable bases 100 respectively located at both ends of the fixed base 200. The adjustable base 100 includes a base 110, an upper hinge The pedestal 120, the lower hinged pedestal 130 and the pedestal translation track 140, the pedestal translation track 140 is set on the pedestal foundation 110, the lower hinged pedestal 130 is movably arranged on the pedestal translation track 140, between the upper hinged pedestal 120 and the lower hinged pedestal 130 It is hinged by the hinge shaft 160, and a locking assembly 170 is provided between the upper hinged base 120 and the lower hinged base 130 to limit the relative rotation of the two, the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com