Discharging device for shot blasting machine

A shot blasting machine and blanking technology, which is applied to used abrasive processing devices, abrasives, metal processing equipment, etc., can solve problems such as time-consuming and labor-intensive, and achieve the effect of reducing impact sound and avoiding manual sorting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

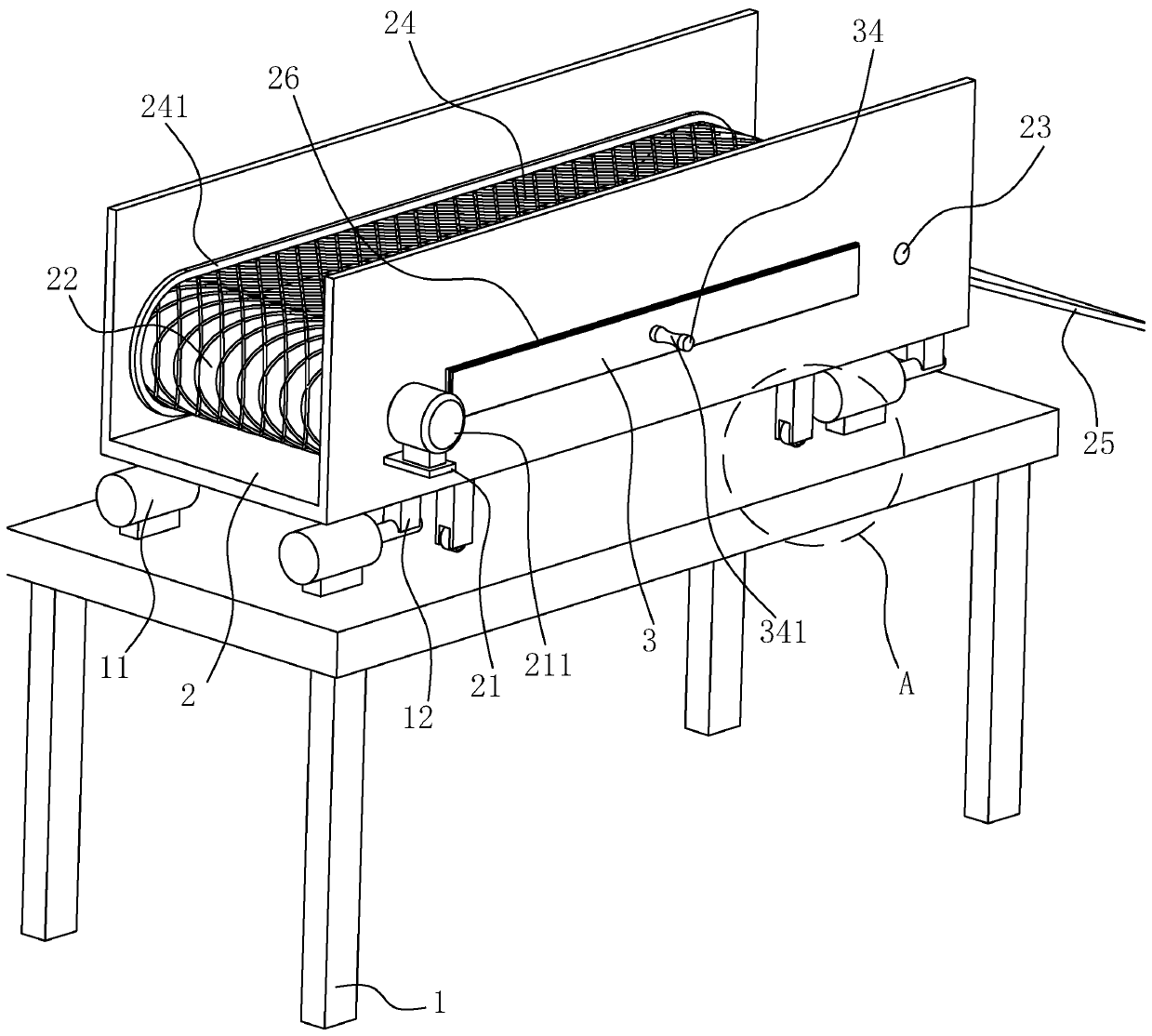

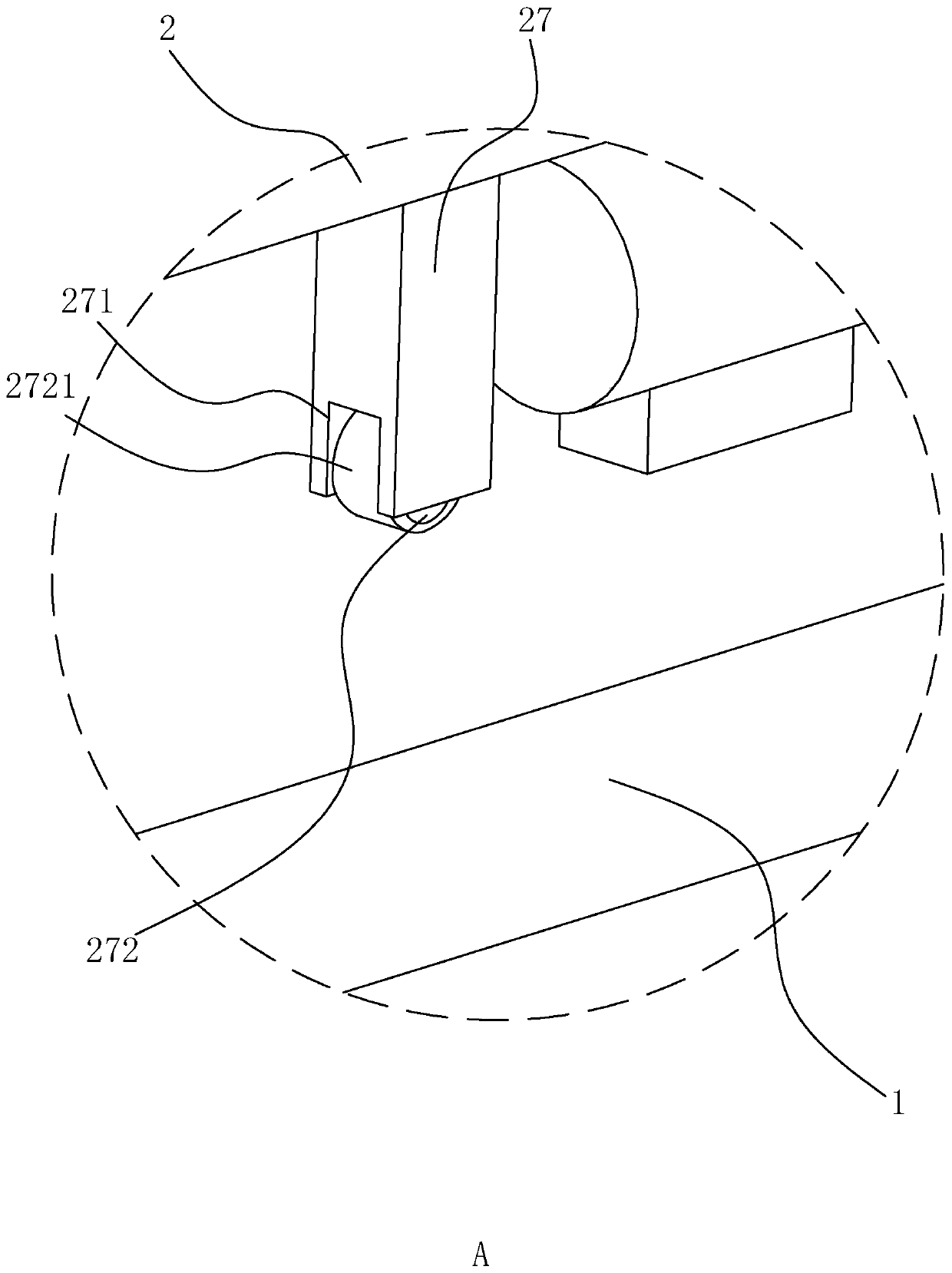

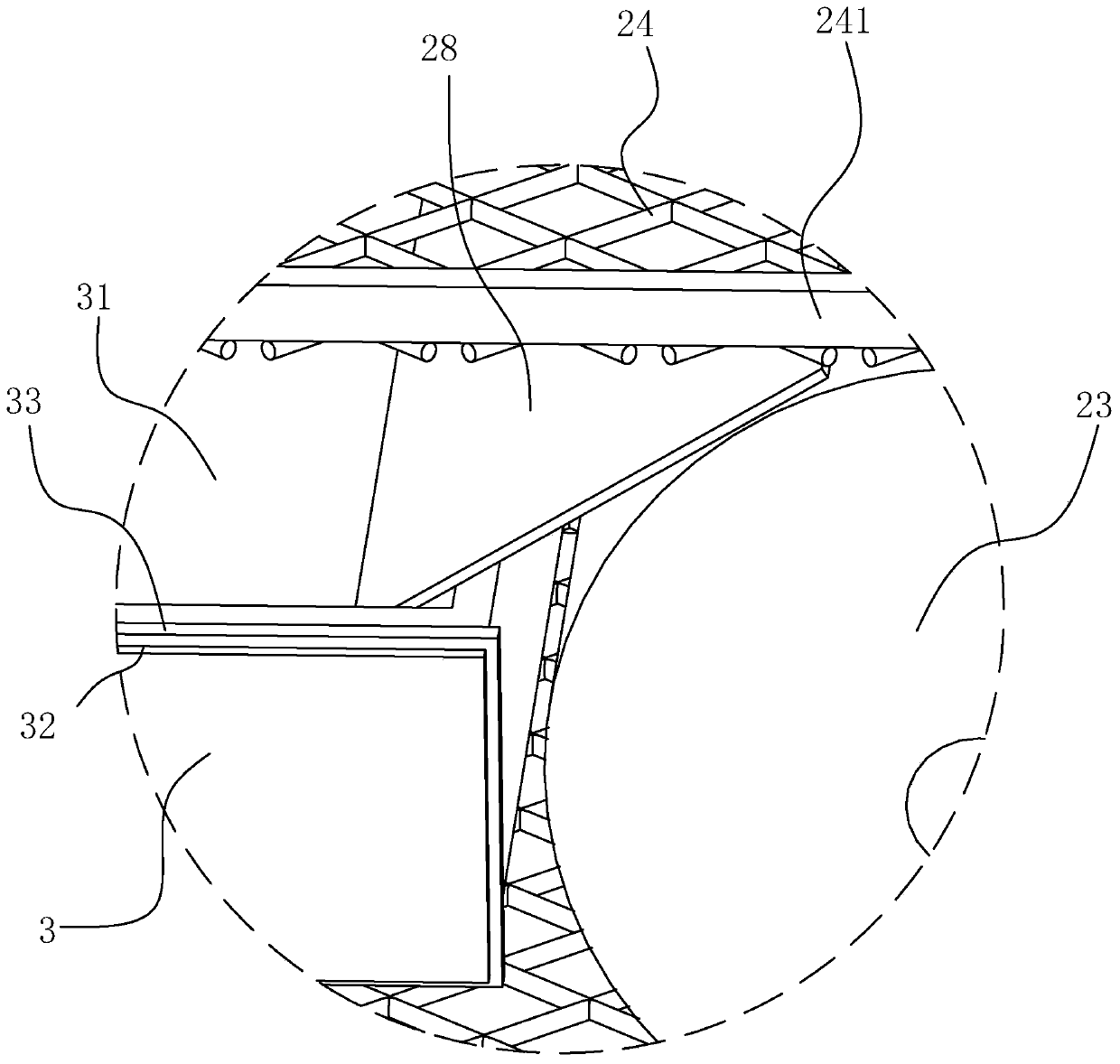

[0038] A blanking device for shot blasting machine, refer to figure 1, which includes a support frame 1 and several cylinders 11 located on the support frame 1, several cylinders 11 are horizontally welded on the top wall of the support frame 1, several cylinders 11 are arranged in the same direction, and the ends of the piston rods of the cylinders 11 are welded with support blocks 12; The top wall of the support block 12 is welded with a sorting frame 2; the side wall of the sorting frame 2 is integrally formed with a driving frame 21, and the driving frame 21 is welded with a driving part 211, and the driving part 211 is preferably a servo motor. The length direction is consistent with the direction of motion of the piston rod of the cylinder 11; the side wall of the sorting rack 2 in the width direction and positioned in the horizontal direction is provided with a driving roller 22, and the driving roller 22 is connected to the sorting rack 2 through bearing rotation, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com