Processing method for hollow anchor rod

A processing method and bolt technology, which is applied in the installation of bolts, earthwork drilling, and threaded products, can solve the problems of small internal space, affecting performance, and large loss of grouting pressure attenuation, achieving low cost, The effect of increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] At present, the heating method of the hollow anchor is mainly: the hot-rolled seamless steel pipe or the cold-rolled seamless steel pipe is directly rolled into shape by the anchor rolling mill. Although the cost of this anchor production process is low, there is a phenomenon of insufficient strength or toughness. That is, the comprehensive mechanical properties are low. If you want to greatly improve the comprehensive mechanical properties of the hollow bolt, heat treatment is often used.

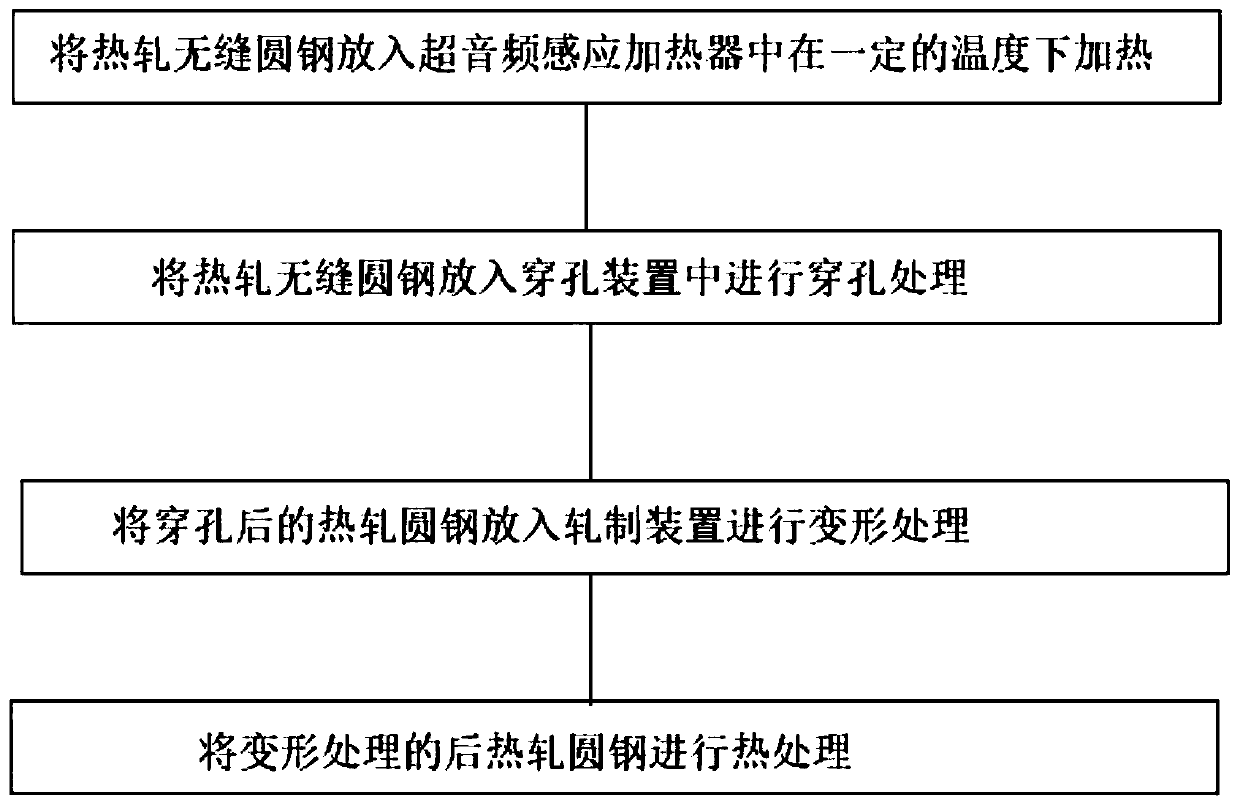

[0021] as attached figure 1 As shown, a hollow anchor rod processing method, the materials and devices used in the hollow anchor rod processing include: hot-rolled seamless round steel, super-audio frequency induction heater, perforation device, rolling device, spray device, heat treatment device, the steps of the hollow bolt processing method are:

[0022] S1: Put hot-rolled seamless round steel into the super-audio frequency induction heater and heat to 970°C;

[0023] S2: Furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com