Sludge carbon-based nanocluster magnesium oxide catalyst, preparation method and applications thereof

A nano-cluster, sludge carbon technology, applied in physical/chemical process catalysts, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve problems such as low uniformity, blocking of carrier voids, and large catalyst particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A preparation method of sludge carbon-based nano-cluster magnesium oxide catalyst, specifically comprising the following steps:

[0055] S1. Using residual sludge from municipal sewage treatment plants as a precursor material, coupled with paint slag and zinc benzoate as a pore-forming agent, a sludge carbon material with three-level structural pores, including macropores, mesopores, and micropores, was prepared. denoted as SC PS-Zn ;

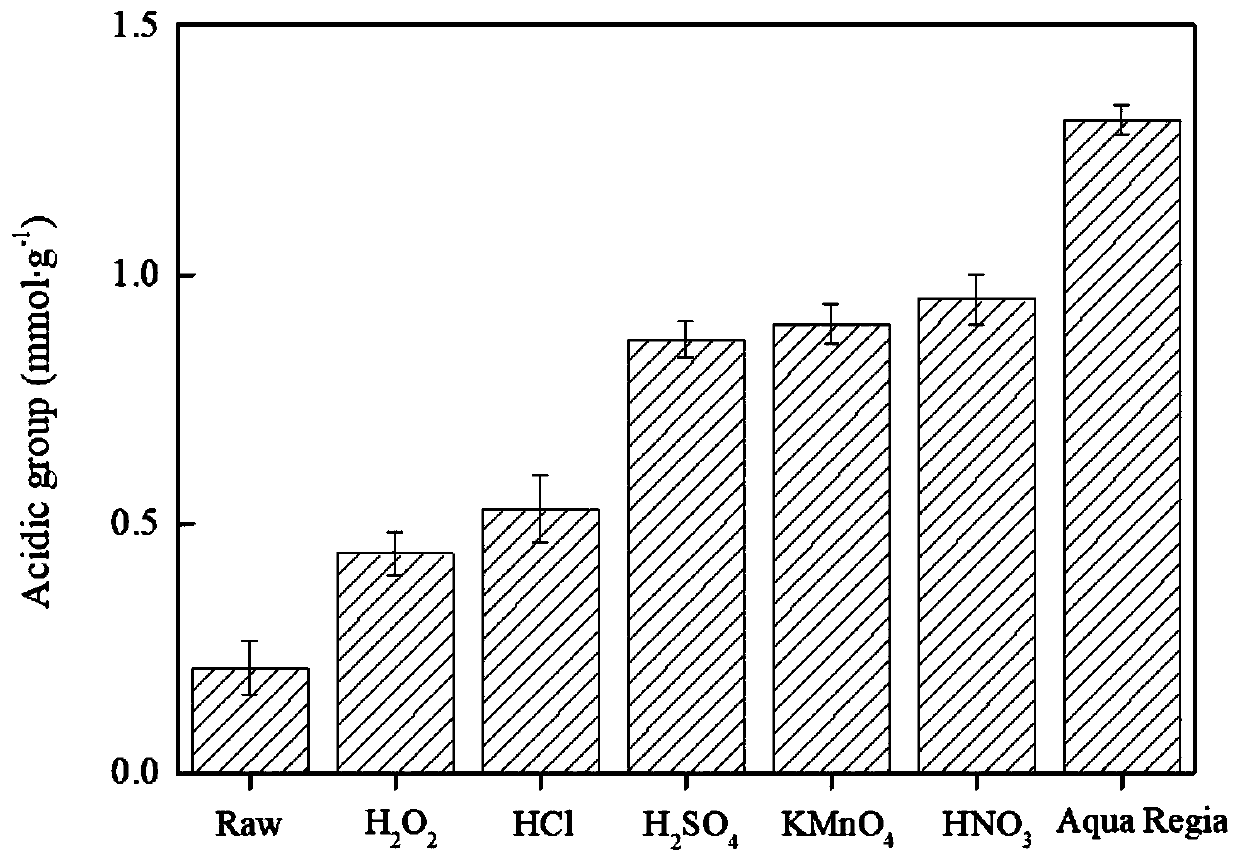

[0056] S2. Weigh 2g of SC PS-Zn , add 1mol L -1 HNO 3 -3HCl 40mL, carry out surface carboxylation treatment under the condition of hydrothermal 150℃, 10h, after natural cooling, use deionized water to clean the residual oxidant (HNO 3 -HCl), dried and stored for later use, denoted as SC PS-Zn (AR);

[0057] S3. Using modified material SC PS-Zn (AR) is used as an adsorbent to adsorb magnesium ions in magnesium nitrate solution, and by controlling the contact time between the adsorbent and the adsorbate, the SC PS-Zn (AR) Carboxyli...

Embodiment 2

[0060] The influence of condition in the preparation process of embodiment 2

[0061] 1. To adopt SC PS-Zn Cause Analysis

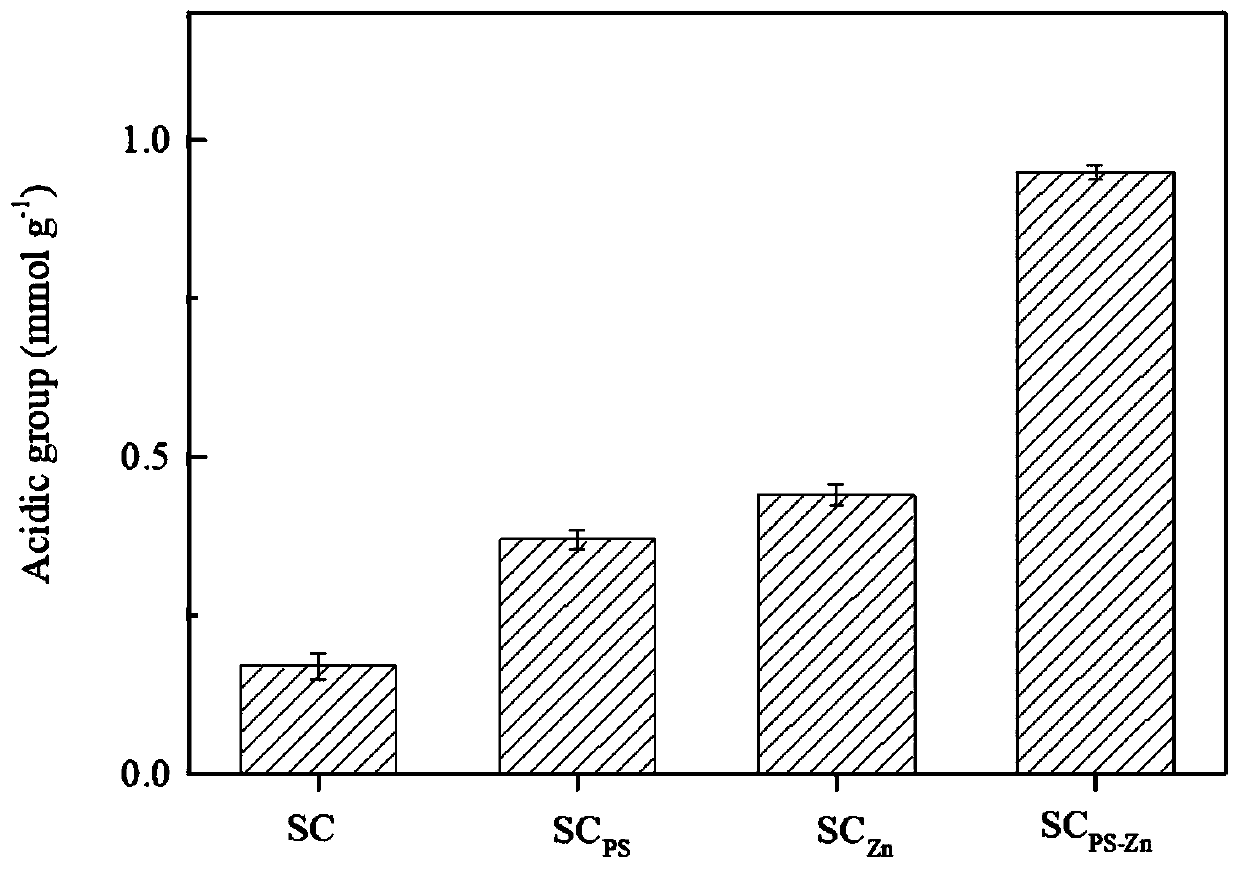

[0062] Using nitric acid as an oxidant, the non-porous, macroporous, micro-mesoporous, microporous-mesoporous-macroporous sludge carbon materials (SC, SC PS 、SC Zn 、SC PS-Zn ) for surface carboxylation treatment, and its carboxylation effect was studied, and the content of acidic functional groups on the surface of different materials after carboxylation was determined by Boehm titration.

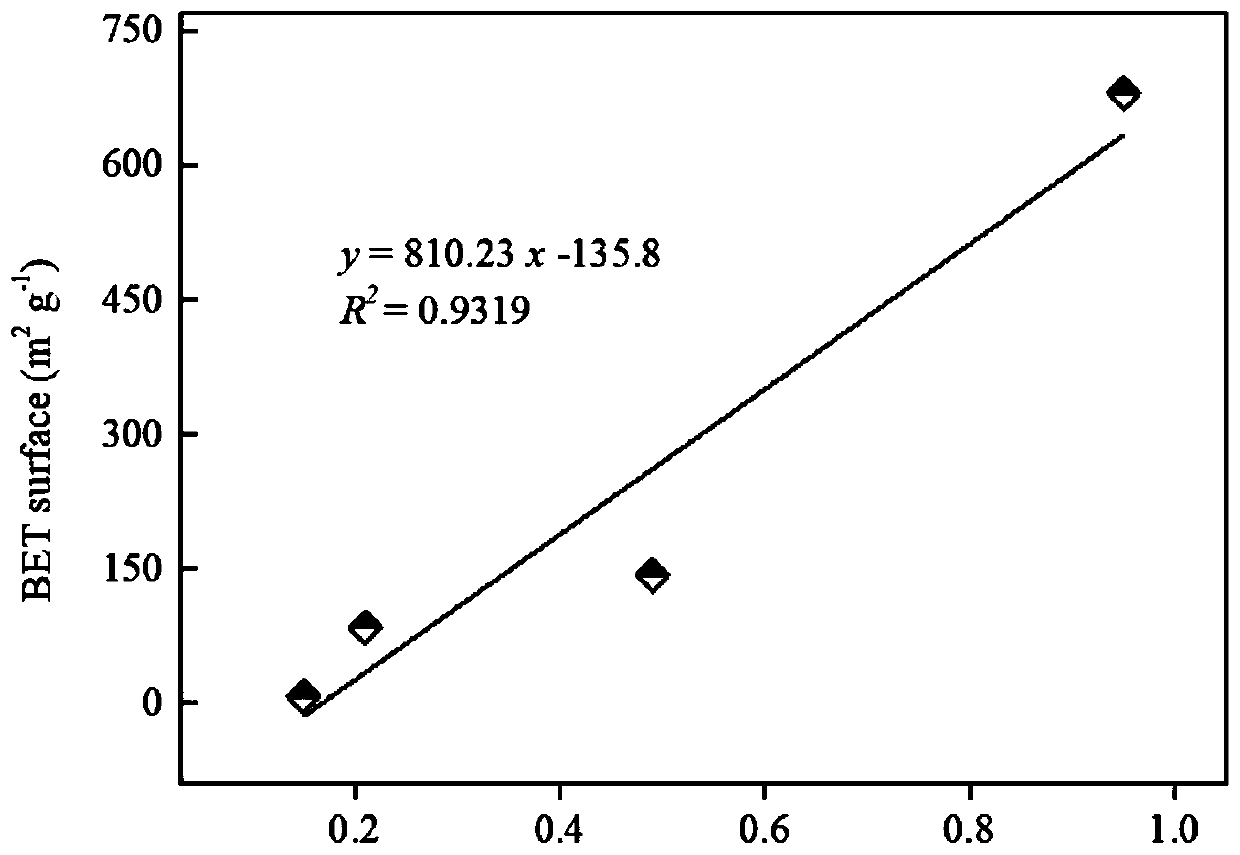

[0063] The measured results are as figure 1 shown by figure 1 It can be seen that different sludge carbon materials modified under the same hydrothermal conditions have a hierarchical pore structure sludge carbon (SC PS-Zn ) surface contains the highest amount of acidic groups (Acidic group), which is 0.95mmol L -1 , is a micro-mesoporous sludge carbon material (SC Zn ) is 1.94 times that of macroporous sludge carbon material (SC PS ) is 4.25 times that of slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com