Production method of protective clothing

A production method and technology of protective clothing, applied in the field of medical protective clothing production and protective clothing production, can solve the problems of waste generation and low production efficiency of protective clothing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

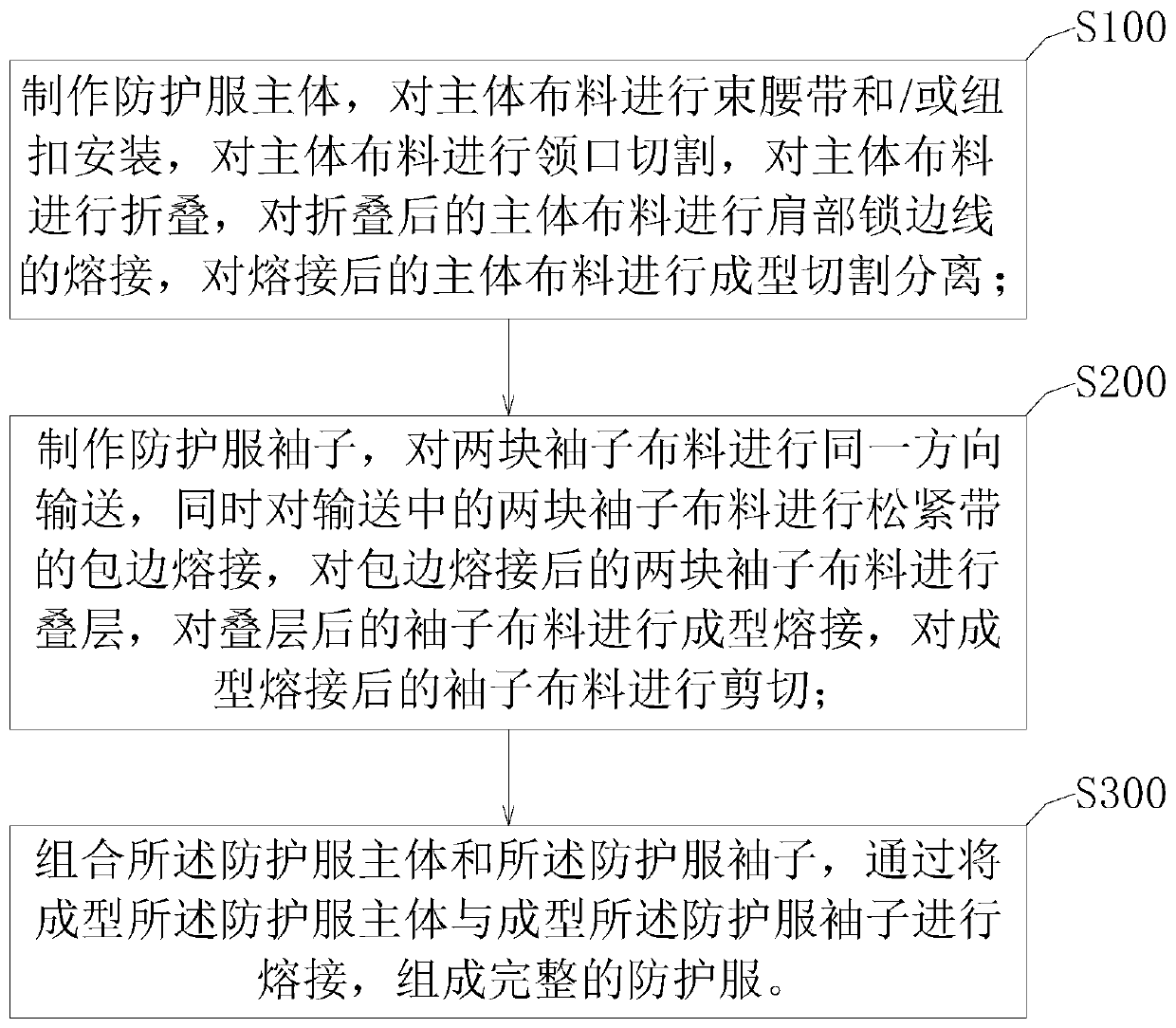

[0087] In another embodiment of the present invention, as figure 2 and Figure 6-11 As shown, the step S100 specifically includes the following steps:

[0088] S110: Servo-unwinding and conveying the main body fabric 10 along a working direction, by performing servo unwinding and conveyance on the main body fabric 10, realizing the adjustment of the conveying speed of the main body fabric 10 and the control of the stop timing of the conveyance in the whole process ;

[0089] S120: Perform welding of the waistband 20 on the upward surface of the main fabric 10 being transported, and perform ultrasonic welding on the upward surface of the main fabric 10 during the conveying process to realize the output molding protection It is not necessary to assemble the main body of the protective clothing with a separate waist belt 20, which saves more procedures and improves efficiency. The waist belt 20 after welding is arranged along the direction perpendicular to the working directio...

Embodiment 2

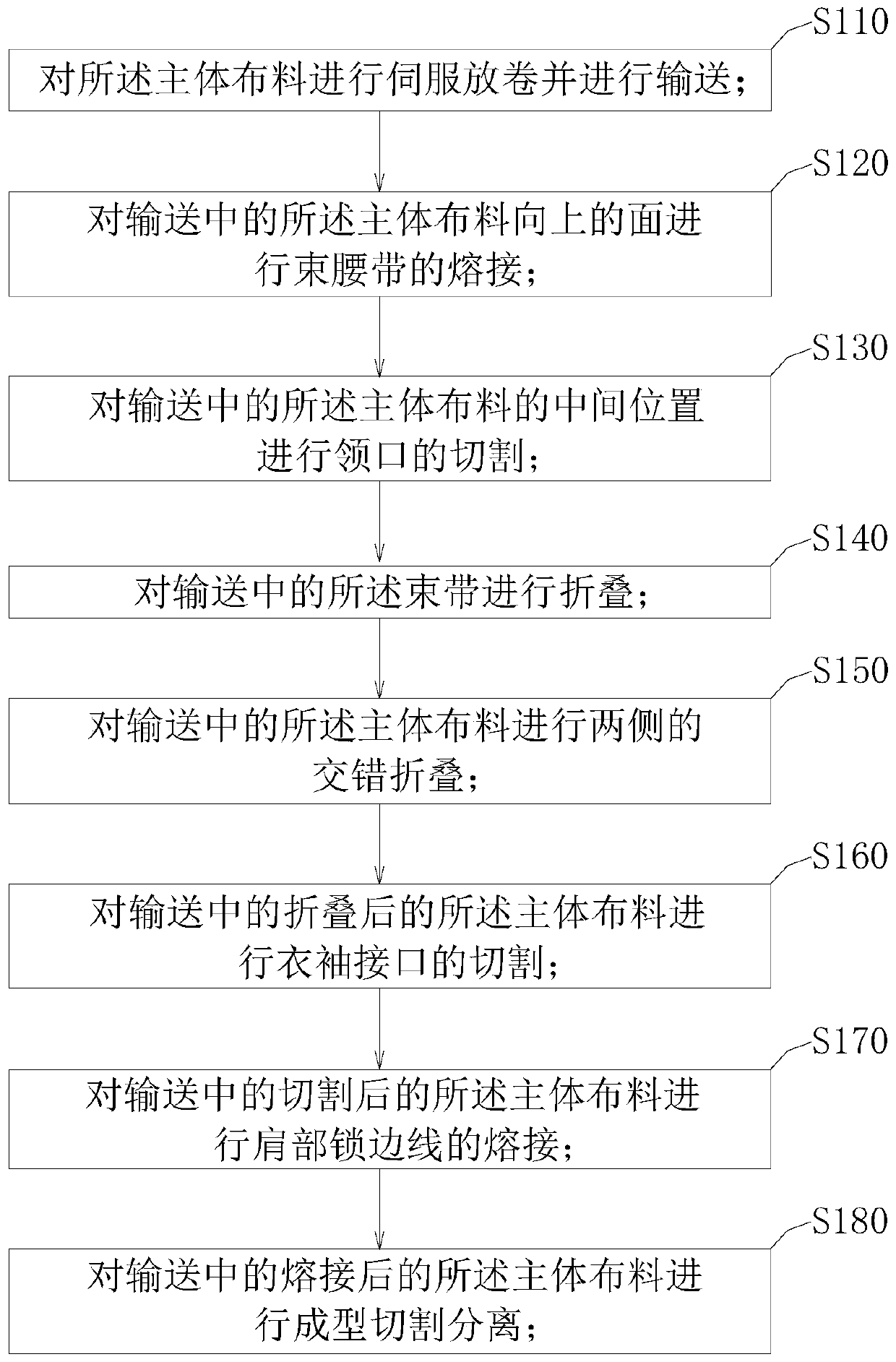

[0116] like image 3 and Image 6 As shown, in this embodiment, the main difference from Embodiment 1 is that the step S100 specifically includes the following steps:

[0117] S110: Servo unwinding and conveying the main body fabric 10 along a working direction;

[0118] S120: Perform welding of the waist belt 20 on the upward surface of the main body fabric 10 being conveyed, and arrange the waist belt 20 after welding along a direction perpendicular to the working direction;

[0119] S130: cutting the neckline 11 at the middle position of the main body fabric 10 being conveyed;

[0120] S140: Fold the waist belt 20 being transported, and arrange the folded waist belt 20 along the working direction;

[0121] S150: performing interfolding on both sides of the main body fabric 10 being transported;

[0122] S160: Cutting the sleeve interface 13 on the folded main body fabric 10 being conveyed;

[0123] S170: Perform welding of the shoulder seam line 14 on the cut main body...

Embodiment 3

[0128] like Figure 4 and Image 6 As shown, in this embodiment, the main difference from Embodiment 1 is that the step S100 specifically includes the following steps:

[0129] S110: Servo unwinding and conveying the main body fabric 10 along a working direction;

[0130] S120: cutting the neckline 11 at the middle position of the main body fabric 10 being transported;

[0131] S130: Assembling the button 12 at the edge positions on both sides of the main body fabric 10 being conveyed;

[0132] S140: performing interfolding on both sides of the main body fabric 10 being transported;

[0133] S150: Cutting the sleeve interface 13 on the folded main body fabric 10 being conveyed;

[0134] S160: Perform welding of the shoulder seam line 14 on the cut main body fabric 10 being conveyed;

[0135] S170: Forming, cutting and separating the welded main body fabric 10 being transported.

[0136] In the production method of the main body of the protective clothing in the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com