Preparation method of yellowing-resistant industrial-grade glycerol

An industrial-grade, anti-yellowing technology, applied in coatings and other directions, can solve problems such as limiting application effects and color interference, and achieve the effects of improving UV shielding, preventing yellowing, and improving anti-yellowing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

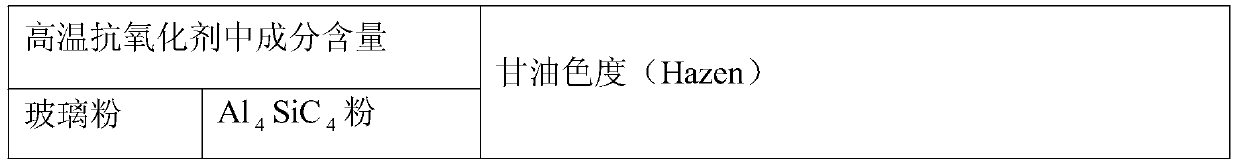

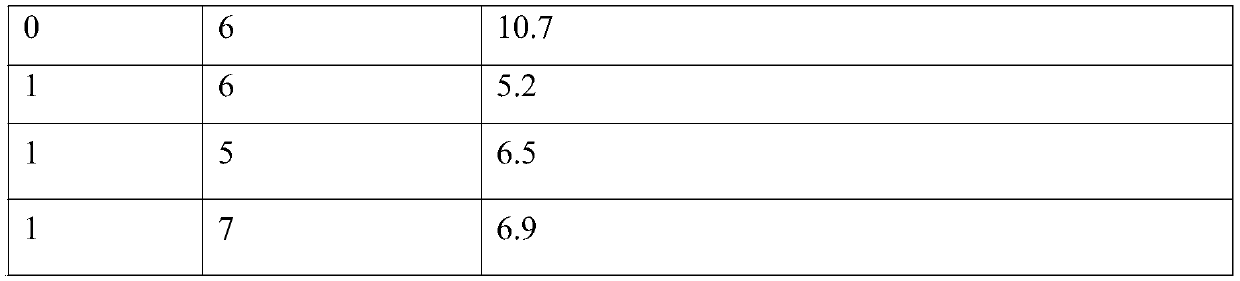

Image

Examples

Embodiment 1

[0024] A kind of preparation method of anti-yellowing technical grade glycerin of the present embodiment, comprises the following steps:

[0025] Step 1, preparation of filling liquid: first add n-decane to the high-temperature reactor, then add carbonate with 5% of the total amount of n-decane, raise the temperature of the high-temperature reactor to 700°C, and then add n-decane The modified rice husk ash with 3% total amount of decane was first stirred at a high speed at a speed of 1000r / min for 20min, and then stirred at a low speed at a speed of 300r / min for 50min, and the filling liquid was obtained after the stirring was completed;

[0026] Step 2, preparation of high temperature self-wetting agent: Cr 2 o 3 The powder is first added to the melting furnace for smelting treatment until it is completely melted, then Ni powder, Al powder and lanthanum nitrate are added in sequence, and the smelting is continued for 10 minutes. Self-wetting agent;

[0027] Step 3, weighin...

Embodiment 2

[0037] A kind of preparation method of anti-yellowing technical grade glycerin of the present embodiment, comprises the following steps:

[0038] Step 1, preparation of filling liquid: first add n-decane to the high-temperature reactor, then add carbonate with 11% of the total amount of n-decane, raise the temperature of the high-temperature reactor to 900°C, and then add n-decane The modified rice husk ash with 6% total amount of decane was first stirred at a high speed of 1400r / min for 30min, and then stirred at a low speed of 400r / min for 60min, and the filling liquid was obtained after the stirring was completed;

[0039] Step 2, preparation of high temperature self-wetting agent: Cr 2 o 3 The powder is first added to the melting furnace for smelting treatment, and smelted until it is completely melted, then Ni powder, Al powder and lanthanum nitrate are added in sequence, and the smelting is continued for 20 minutes. Self-wetting agent;

[0040]Step 3, weighing of raw ...

Embodiment 3

[0051] A kind of preparation method of anti-yellowing technical grade glycerin of the present embodiment, comprises the following steps:

[0052] Step 1, preparation of filling liquid: first add n-decane to the high-temperature reactor, then add carbonate with 8% of the total amount of n-decane, raise the temperature of the high-temperature reactor to 800°C, and then add n-decane The modified rice husk ash with 4.5% total amount of decane is first stirred at a high speed at a speed of 1200r / min for 25 minutes, and then stirred at a low speed of 350r / min for 55 minutes. After the stirring is completed, a filling liquid is obtained;

[0053] Step 2, preparation of high temperature self-wetting agent: Cr 2 o 3 The powder is first added to the melting furnace for smelting treatment, and smelted until it is completely melted, then Ni powder, Al powder and lanthanum nitrate are added in sequence, and the smelting is continued for 15 minutes. Self-wetting agent;

[0054] Step 3, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com