Pneumatic tires for two-wheeled motor vehicles

A technology for motorized two-wheeled vehicles and pneumatic tires, which is applied in the directions of motor vehicles, motorcycle tires, tire parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

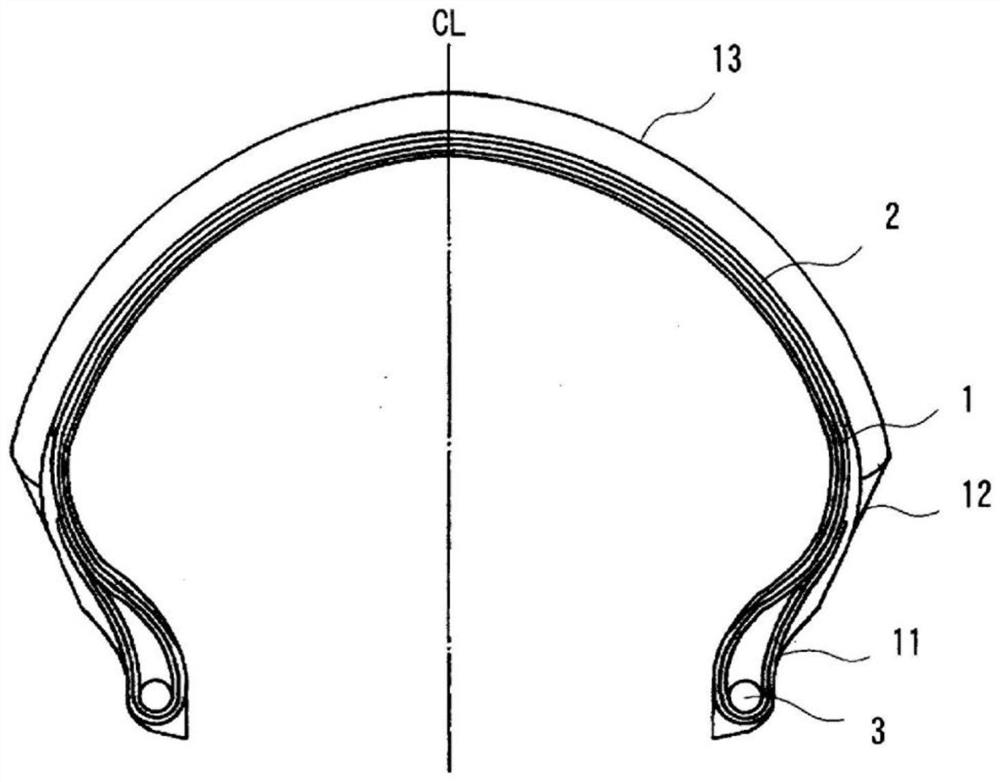

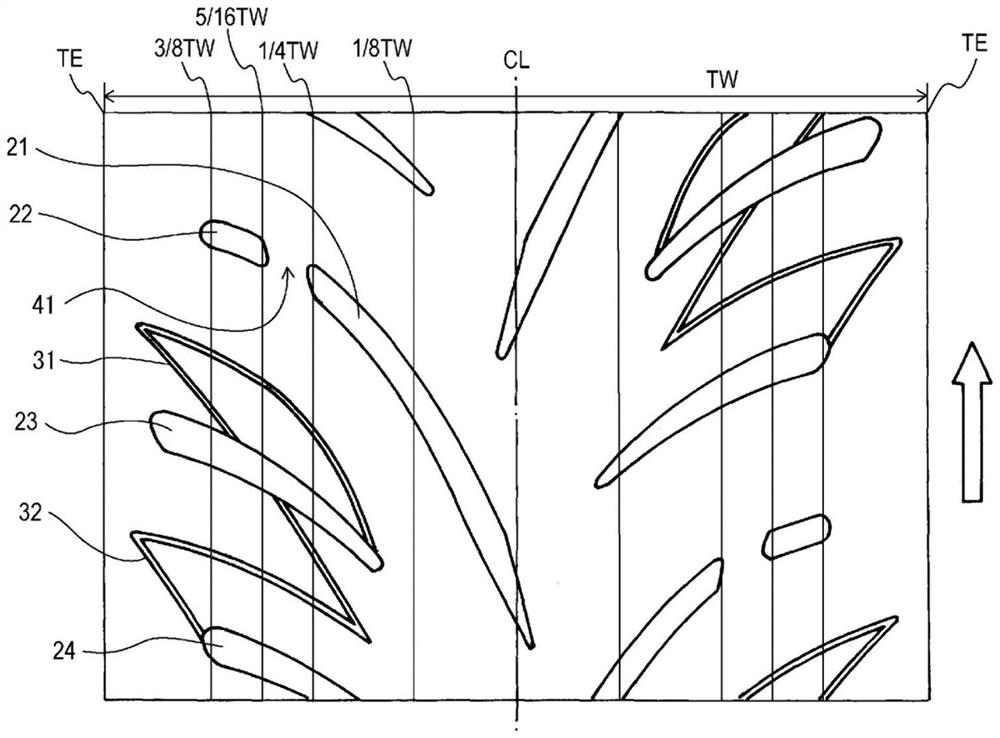

[0044] According to the conditions shown in the table below, according to the tire size MCR120 / 70ZR17M / C figure 1 , figure 2 A pneumatic radial tire for motorcycles according to Example 1 having the cross-sectional structure and tread pattern shown. The carcass 1 has two layers, and rayon is used as a reinforcing cord. In addition, as the belt layer 2 , a single helix belt in which rubber-coated steel cords are helically wound is used.

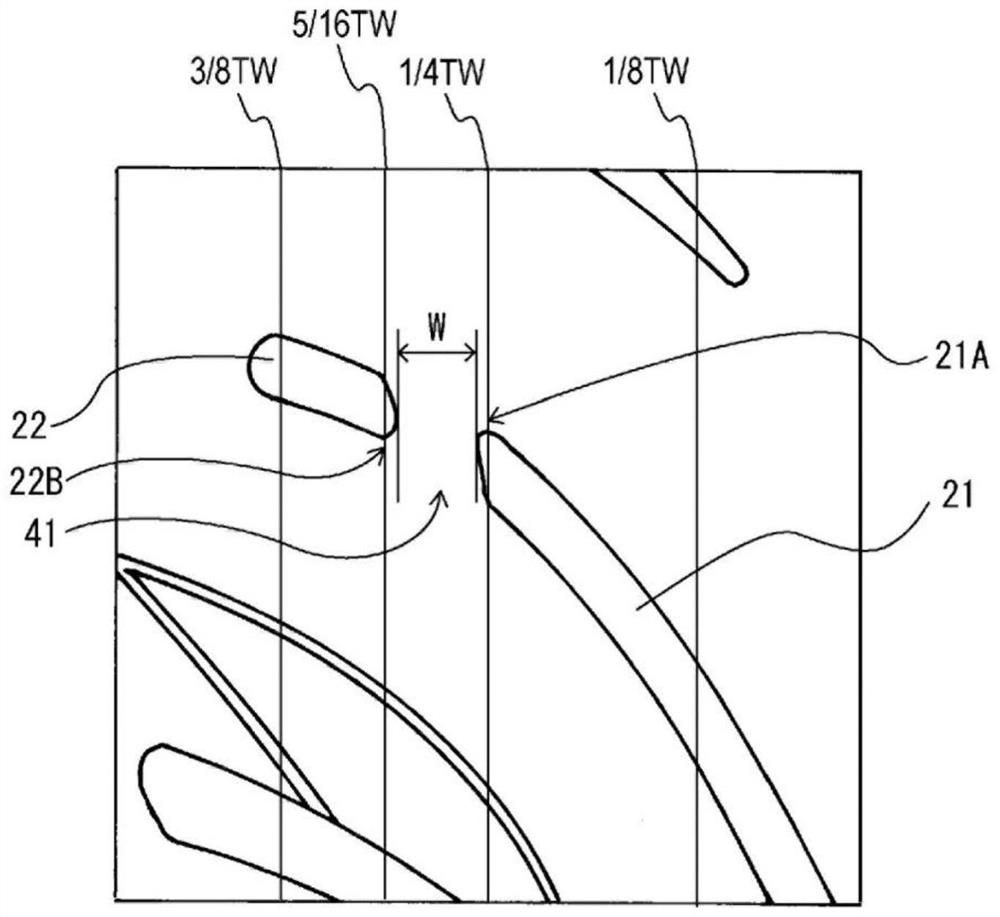

[0045] In the tire of Example 1, the first inclined groove extending obliquely in the same direction as the tire rotation direction from the vicinity of the tire equator toward the outer side in the tire width direction, and the tire width arranged on the first inclined groove are provided on the tire contact surface portion. Short slot in extension of direction outboard end. In addition, the outer end in the tire width direction of the first inclined groove is located near a point offset from the tire equator to the outside in the tire w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com