Riding edge internal lock type retainer

A cage and inner-locking technology, applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as lack of bearing performance, achieve simple structure, ensure high speed and high precision, and reduce friction and heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

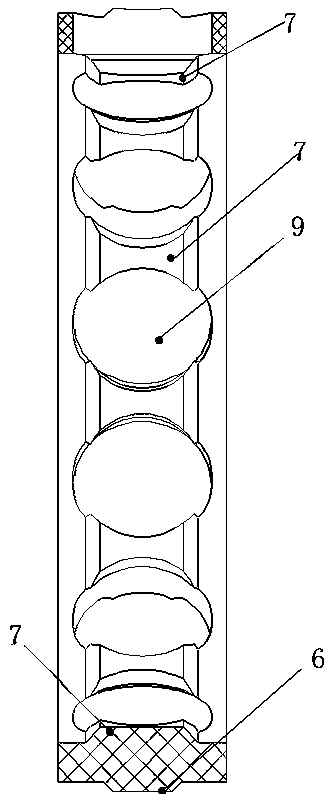

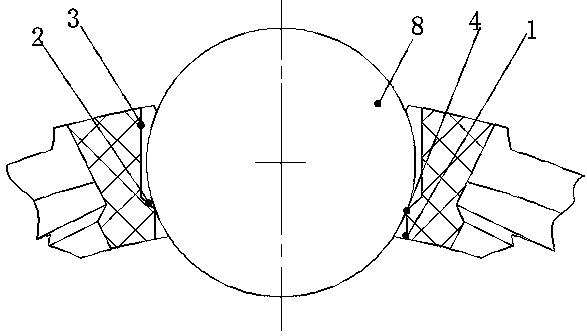

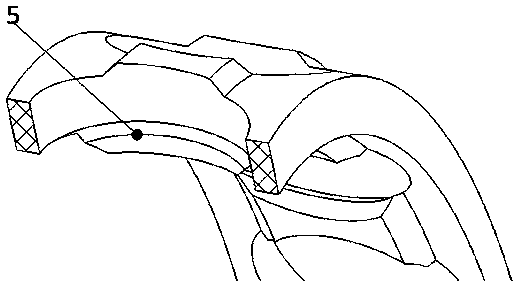

[0029] Riding inner locking cage, the cage pocket 9 is set from the inside to the outside as the first cylindrical section 1, the conical section 2 and the second cylindrical section 3; the cross-sectional diameter of the first cylindrical section 1 is smaller than the second cylindrical section 3 The cross-sectional diameter of the conical section 2 expands from the first cylindrical section 1 to the second cylindrical section 3, and the connecting edge of the first cylindrical section 1 and the conical section 2 is the internal locking position 4 of the cage.

[0030] Further, the axis of the first cylindrical section 1, the axis of the conical section 2 and the axis of the second cylindrical section 3 are coaxial.

[0031] Further, the inner lock position of the cage is in contact with the spherical rolling elements (steel balls 8 ) installed in the cage in two arcs.

[0032] Further, a plurality of outer diameter bosses 6 are arranged on the outer diameter surface of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com