Embedded reinforcing structure and method of bridge expansion device

A technology of expansion device and reinforcement structure, which is applied in the field of pre-embedded reinforcement structure and pre-embedded reinforcement structure of bridge expansion device, which can solve the problems of easy damage, low precision and strength of expansion joint device, fatigue of bridge expansion device, etc. problems, to achieve the effect of increasing steel content, improving anchor strength and installation accuracy, and improving anchor strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

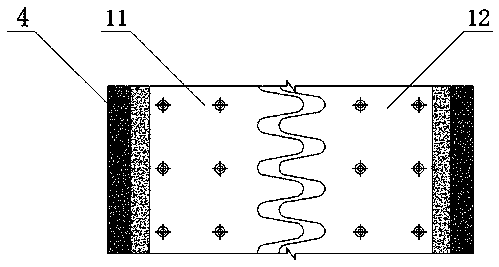

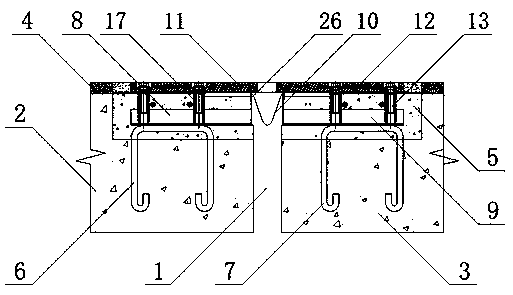

[0065] Specific implementation mode one: see figure 1 , figure 2, the left pre-embedded unit 8 and the right pre-embedded unit 9 include positioning connectors 15 and transverse steel bars 16, and a row of mutually parallel positioning connectors 15 is welded and fixed on the left notch embedded part 6 and the right notch pre-embedded part 7 , the positioning connector 15 is an angle steel, and the positioning connector 15 is vertically fixed with two or more transverse steel bars 16, and the positioning connector 15 is vertically fixed with a slotted nut sleeve 17 or a slotted nut 18, and the slotted nut sleeve Internal threads are provided in the inner hole of the barrel 17 . The position of the long hole nut sleeve 17 or the long hole nut 18 has been accurately positioned in the horizontal and vertical directions, which ensures that the follow-up telescopic device can be installed quickly and accurately, and the installation accuracy is ensured.

specific Embodiment approach 2

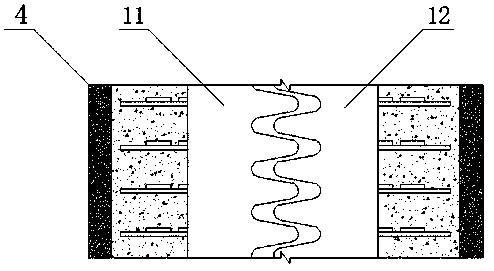

[0066] Specific implementation mode two: see Figure 5 , Image 6 , the left pre-embedded unit 8 and the right pre-embedded unit 9 include positioning connectors 15 and transverse steel bars 16. Compared with the specific embodiment 1, the connection method is different. On the left slot embedded part 6 and the right slot embedded part 7 A row of positioning connectors 15 parallel to each other are respectively welded and fixed. The positioning connectors 15 are angle steels, channel steels or I-beams. The member 15 is perpendicular to the transverse reinforcement 16 . A slotted nut sleeve 17 or a slotted nut 18 is vertically fixed on the positioning connector 15 , and an internal thread is arranged in the inner hole of the slotted nut sleeve 17 . The position of the long hole nut sleeve 17 or the long hole nut 18 has been accurately positioned in the horizontal and vertical directions, which ensures that the follow-up telescopic device can be installed quickly and accuratel...

specific Embodiment approach 3

[0067] Specific implementation mode three: see Figure 5 , Image 6 , the left pre-embedded unit 8 and the right pre-embedded unit 9 include a transverse elongated steel part 19 and a transverse elongated steel part 20, and the left notch embedded part 6 and the right notch pre-embedded part 7 are respectively welded and fixed with two or More than two horizontal long steel pieces 19 are arranged in parallel, and the horizontal long steel pieces 19 are distributed in parallel along the direction of the expansion joint 1, and the horizontal long steel pieces 19 are made of long steel processed parts or steel castings. The steel structure connectors 20 are two and distributed in parallel, and the two transverse elongated steel parts 19 are connected and fixed by a plurality of evenly distributed steel structure connectors 20, and each steel structure connector 20 is fixed with a long hole nut Sleeve 17 or slotted nut 18. The position of the long hole nut sleeve 17 or the long ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com