Method for culturing chlorella by using sludge anaerobic digestion liquid

A technology of anaerobic digestion and sludge anaerobic fermentation, which is applied in anaerobic digestion treatment, methods using microorganisms, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

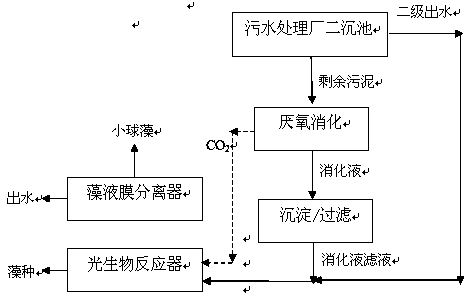

[0028] The present invention utilizes the method for cultivating chlorella of sludge anaerobic digestion liquid such as figure 1 As shown, the residual sludge discharged from the secondary sedimentation tank of the municipal sewage treatment plant is anaerobically digested and the digested liquid is pretreated to remove the suspended solids to obtain the sludge anaerobic fermentation liquid, the sludge anaerobic fermentation liquid and the secondary effluent Mix to adjust the concentration to obtain pretreated wastewater; then enter the photobioreactor for chlorella cultivation, and finally separate the chlorella and purified sewage through the algae liquid membrane separator. The specific control process is as follows.

[0029] (1) Wastewater pretreatment

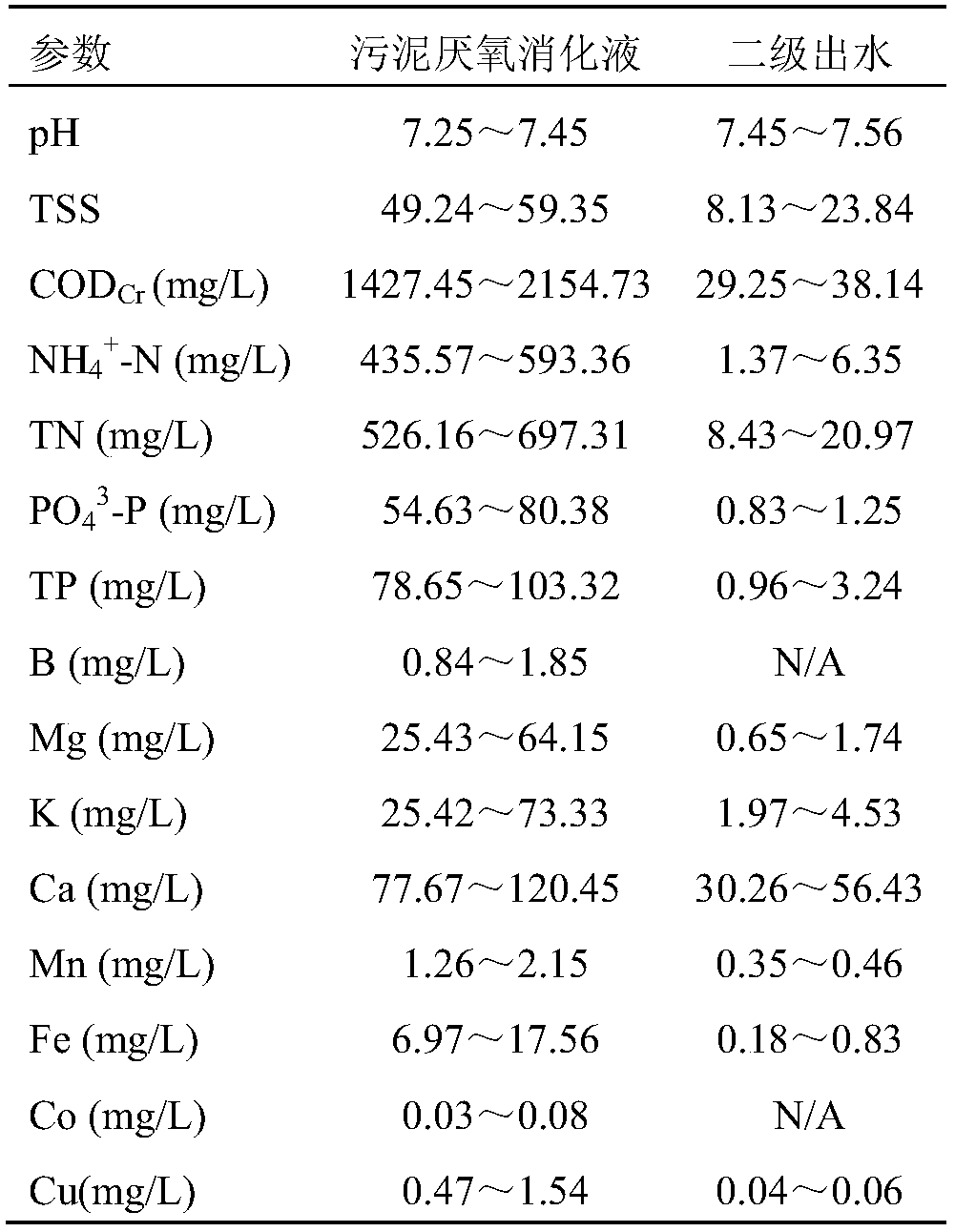

[0030] The total suspended solids concentration (TSS) of sludge anaerobic digestion liquid is as high as 2000 mg / L or more. Such a high concentration of suspended solids will block the light absorption of microalgae, sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com