Electrically conductive resin composition and preparation method thereof

A conductive resin and composition technology, applied in the field of conductive resin composition and its preparation, can solve problems such as difficult products and parts, unevenness, etc., and achieve the effect of excellent elongation and uniform conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

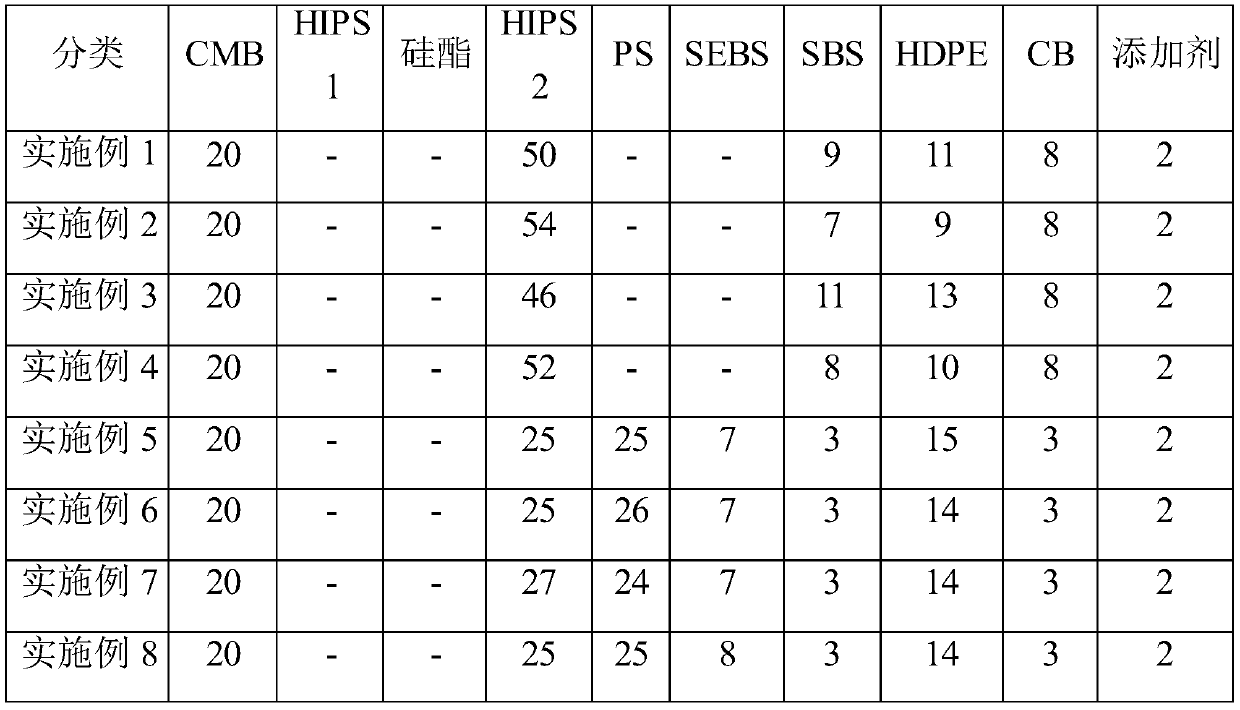

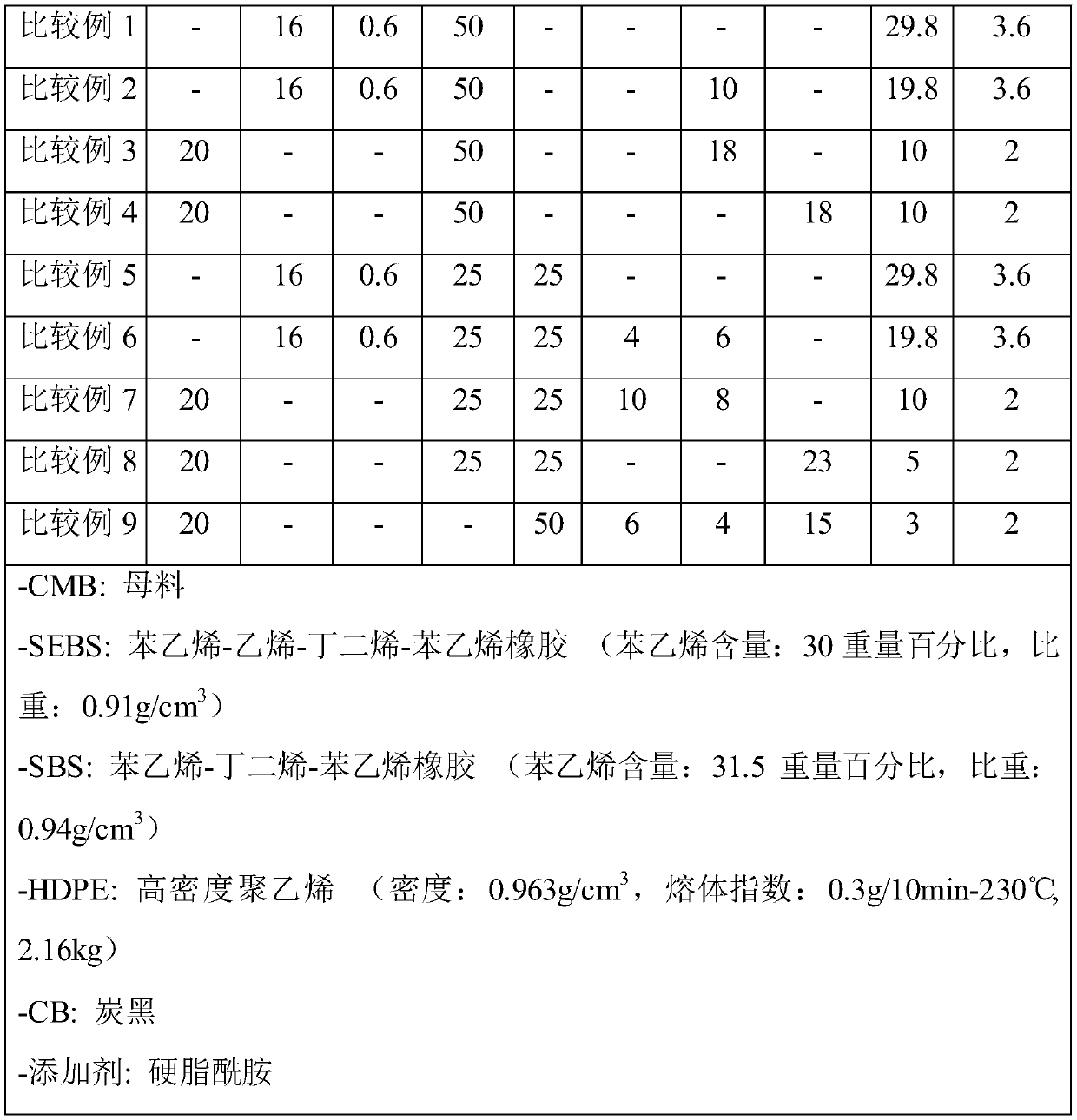

Examples

preparation example Construction

[0085] The preparation method of conductive resin composition

[0086] A method for preparing a conductive resin composition according to another aspect of the present invention may include: a step (a) of mixing a first copolymer comprising a rubber component having an average particle diameter of 1 to 5 μm and a conductive filler to prepare a masterbatch; and Step (b), mixing the above-mentioned masterbatch, the second copolymer including the rubber component with an average particle diameter of 0.1 to 1 μm, the rubber component and the olefin polymer.

[0087] The functions and effects, contents, usable types, etc. of the above-mentioned first copolymer, second copolymer, rubber component, and olefin polymer are the same as those described above.

[0088] That is, the above-mentioned conductive resin composition may firstly prepare a masterbatch by mixing a polymer component and a conductive filler. Besides, other polymer components, rubber components and olefin polymers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com