Bottom gating system for guider

A pouring system and guide technology, which is applied to casting molding equipment, molds, cores, etc., can solve the problems of easy generation of columnar crystals, slag inclusions in castings, and large runout of casting planes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

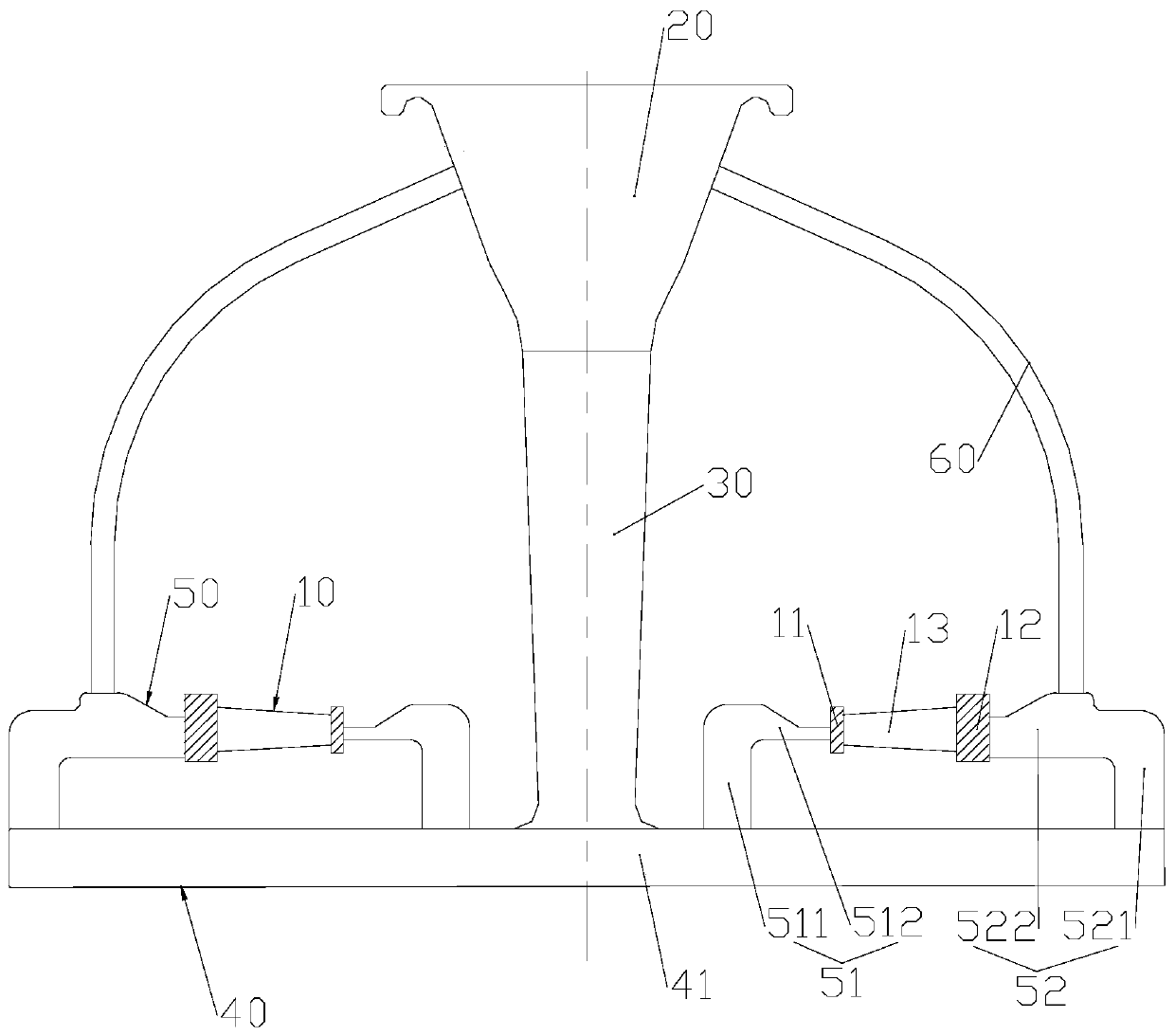

[0029] refer to figure 1 , the preferred embodiment of the present invention provides a guider bottom pouring type pouring system, which is used to fill the guider formwork 10 arranged upside down with the exhaust side of the airfoil formwork 13, so that the guider formwork 10 to form an integral precision casting guide, the guide bottom pouring gating system includes: sprue cup 20, the lower end of sprue cup 20 is connected with a vertical sprue 30, and the bottom end of sprue 30 is connected with a The runner assembly 40 arranged horizontally, the runner assembly 40 is used to divert the filling liquid filled by the sprue 30 and block the slag, so that the slag inclusions mixed in the filling liquid stay in the In the runner assembly 40, the runner assembly 40 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com