Motor-driven bottle body painting device

A motor-driven, bottle-body technology, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of slow painting operation, inconvenient operation, low production efficiency, etc., to ensure processing accuracy and improve painting. The effect of speeding up the painting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

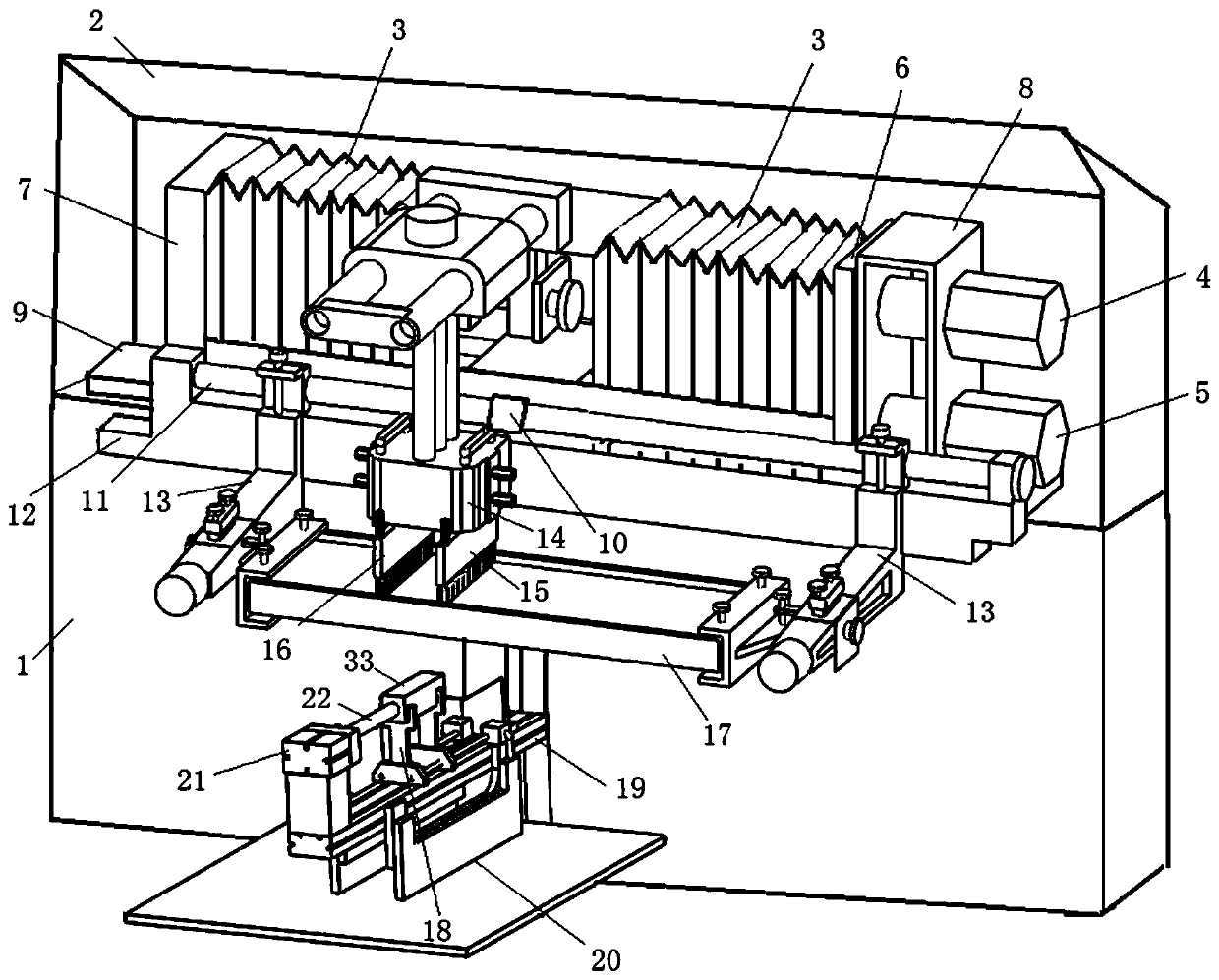

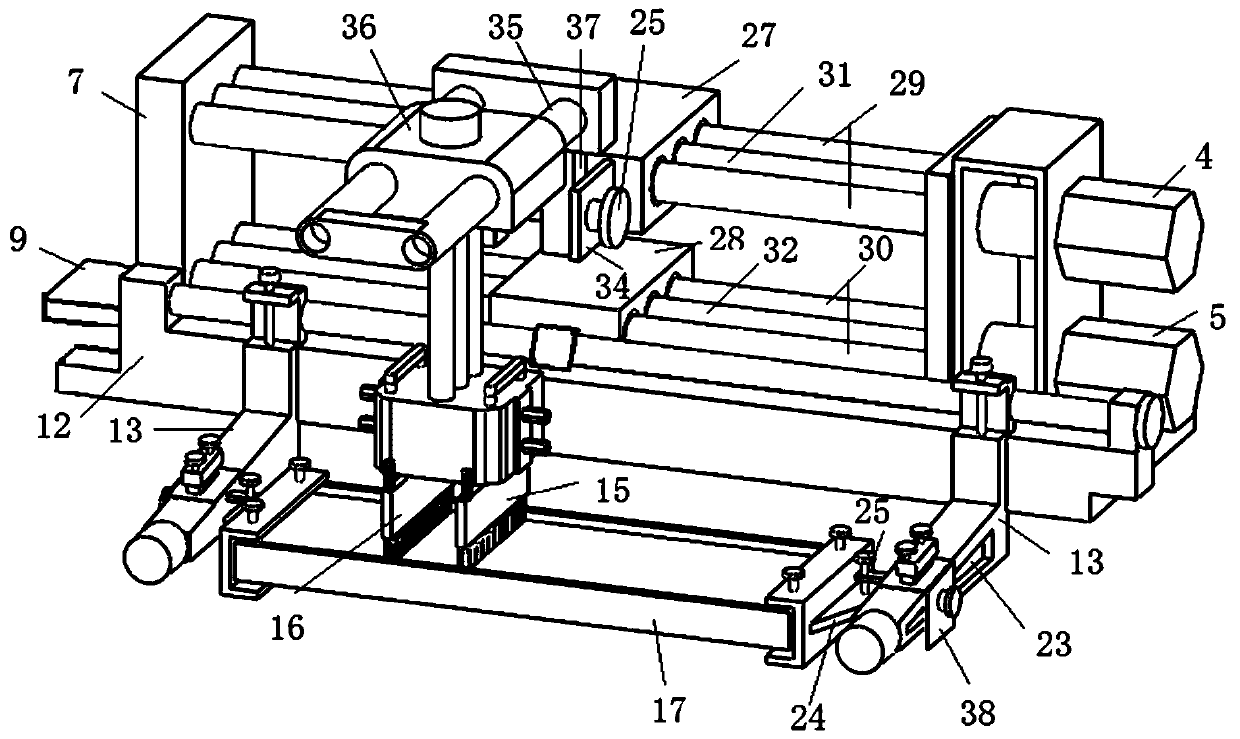

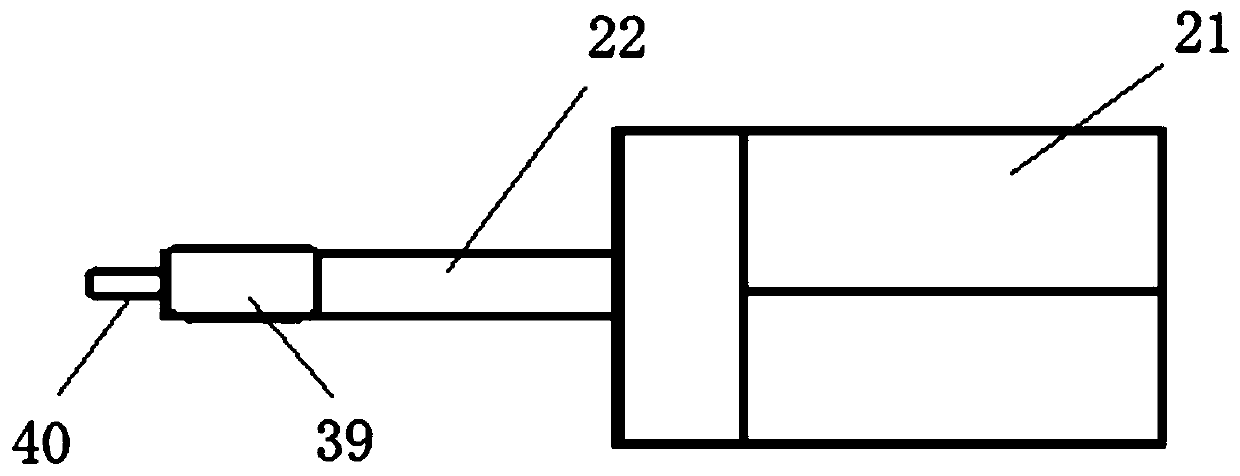

[0029] The invention relates to a motor-driven bottle body painting device, which comprises a machine body 1, an upper cover 2, a painting mechanism, a telescopic protective cover 3, a motor driving mechanism, a screen frame sliding mechanism, and a bottle body adjusting mechanism.

[0030] Body 1 is fixed on the ground, and the top of body 1 is provided with screen frame slide mechanism and loam cake 2, and loam cake 2 is half open shape, and it is fixed on the edge of body 1, and is arranged on the top of screen frame slide mechanism. The motor drive mechanism includes a base plate 9, a first motor 4, a second motor 5, a first screw 31, a second screw 32, a first optical axis 29, a second optical axis 30, a motor holder 8, and a first fixed plate 6. The second fixing plate 7. The bottom plate 9 is fixed on the top of the body 1, the motor holder 8, the first fixed plate 6, and the second fixed plate 7 are fixed on the bottom plate 9, and the corresponding position of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com