Coarse particle tailing discarding sorting system based on hydraulic flotation technology

A sorting system and coarse particle technology, which is applied in the field of coarse particle tailing separation system, can solve the problems of low efficiency of tailing throwing and large crushing particle size, so as to increase the processing capacity of ore dressing, reduce the energy consumption of regrinding, and increase the input The effect of material grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

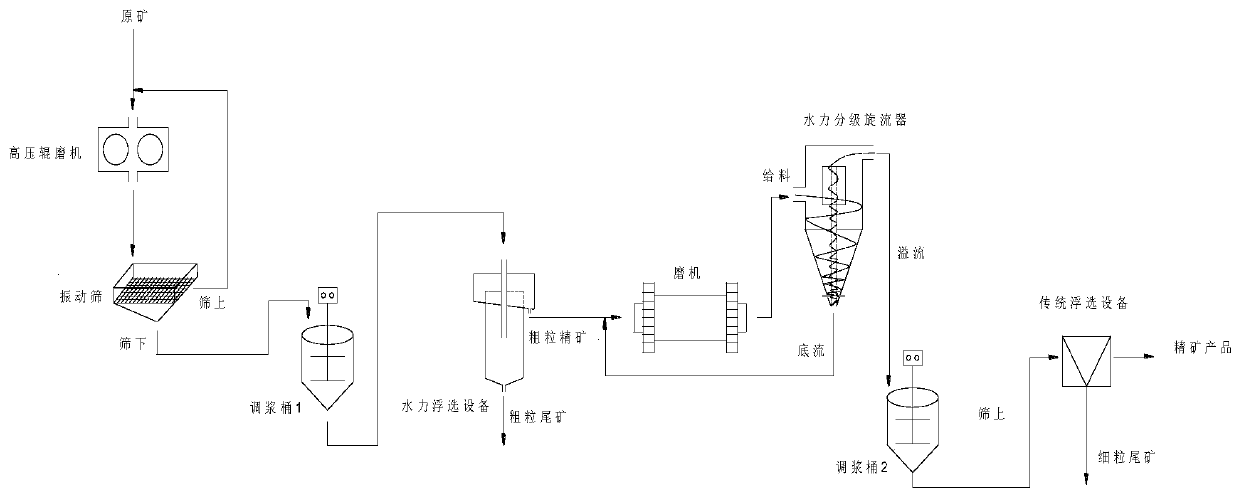

[0025] A sorting system for coarse particle tailings based on hydraulic flotation technology, including the following workflow:

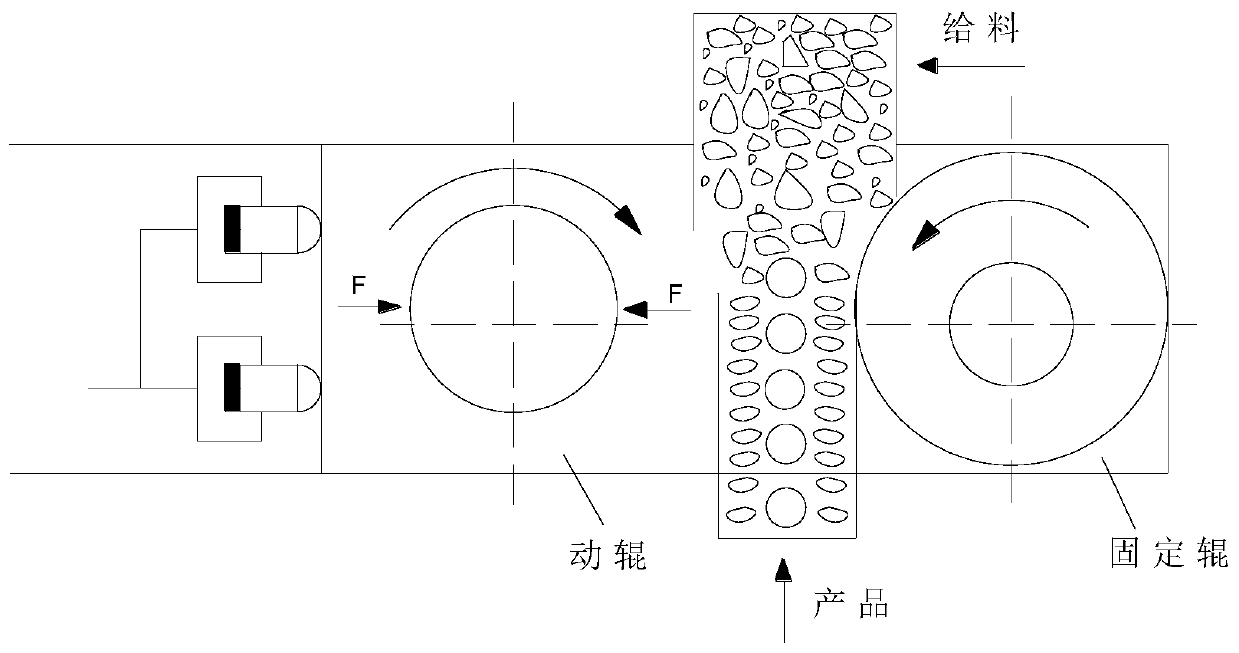

[0026] Process 1: According to the physical properties of the raw ore, adjust the high-pressure roller mill to an appropriate pressure value, and grind the raw ore to a certain range of coarse particle size.

[0027] Process 2: Feed the crushed raw ore into the vibrating screen, and replace the screens with different particle sizes within the range of 1 to 5 mm according to the feeding needs of the hydraulic flotation equipment, and then selectively screen the raw ore.

[0028] Process 3: Feed the mineral under the sieve into the mixing tank 1, add a certain amount and proportion of foaming agent, collector and regulator, and adjust the rotation speed of the stirring paddle to fully mix the ore pulp and the chemical agent.

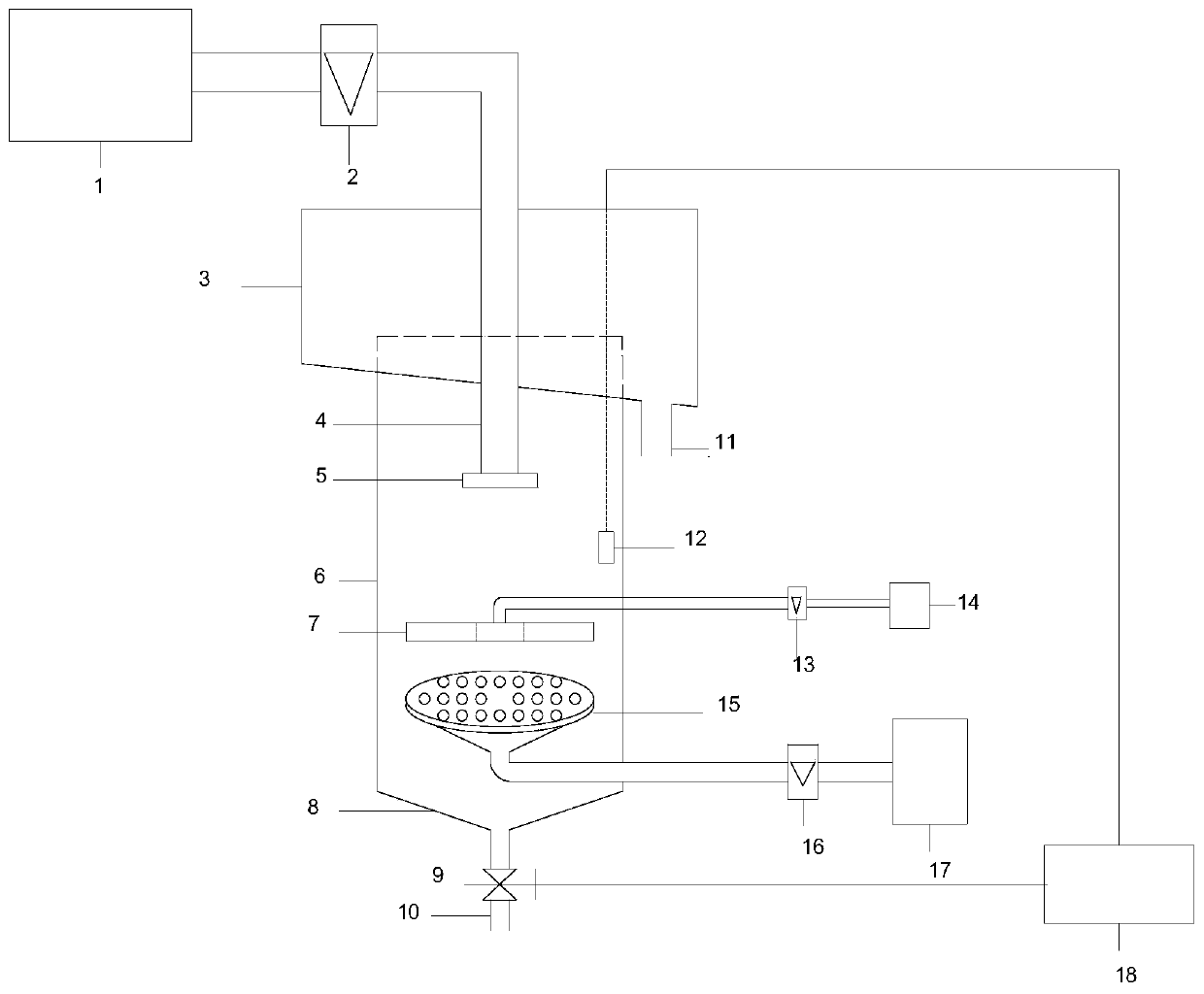

[0029] Process 4: The ore pulp after the upward slurry mixing is fed into the hydraulic flotation equipment, and the low-grade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com