A pollution-free crushing device for medical waste

A shredding device, a technology for medical waste, applied in the direction of drying solid materials without heating, drying chambers/containers, lighting and heating equipment, etc., can solve the problems of garbage compression and insufficient garbage crushing, and achieve the effect of increasing crushing. Practical Strong sex, increase the effect of crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

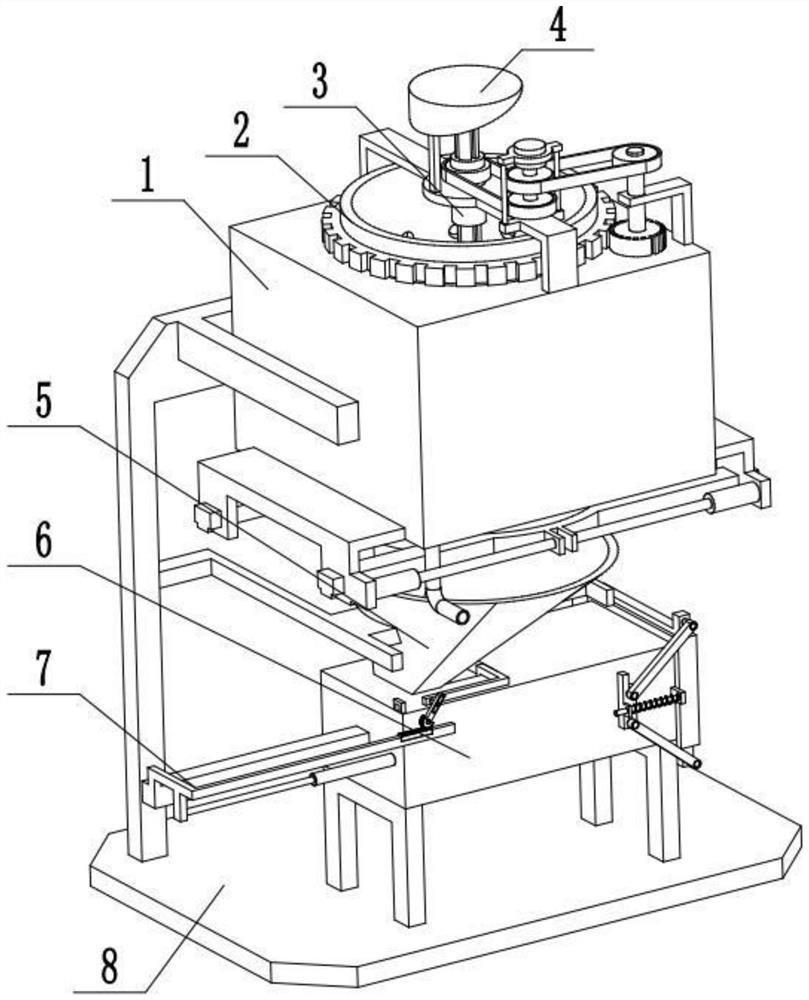

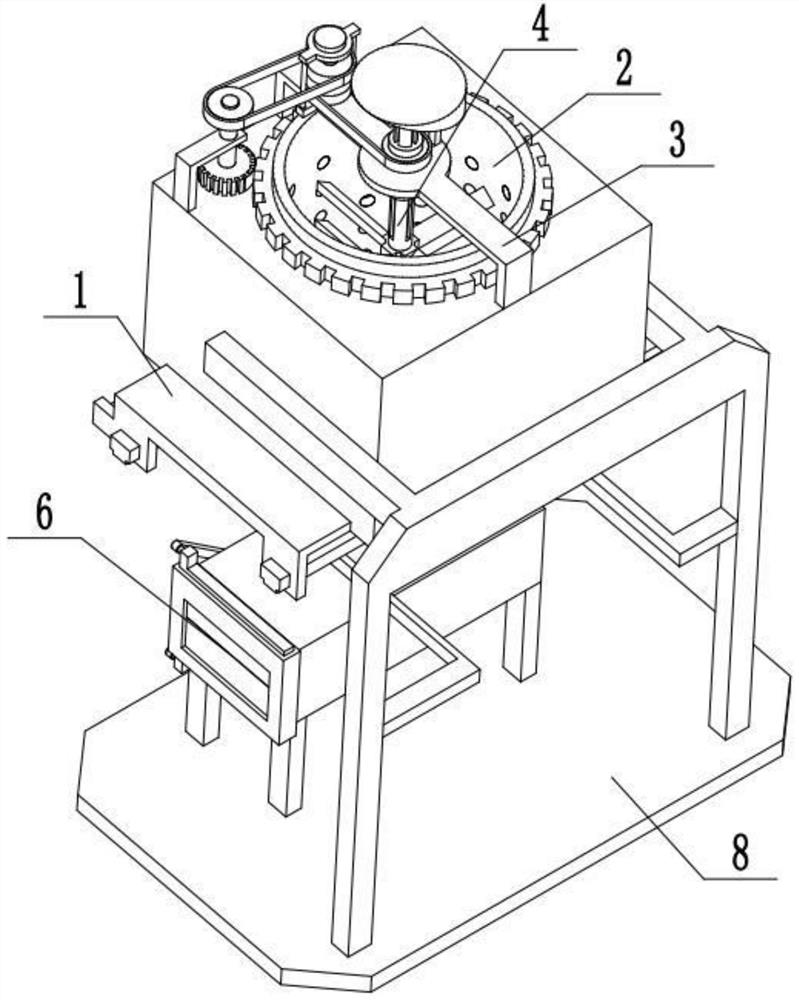

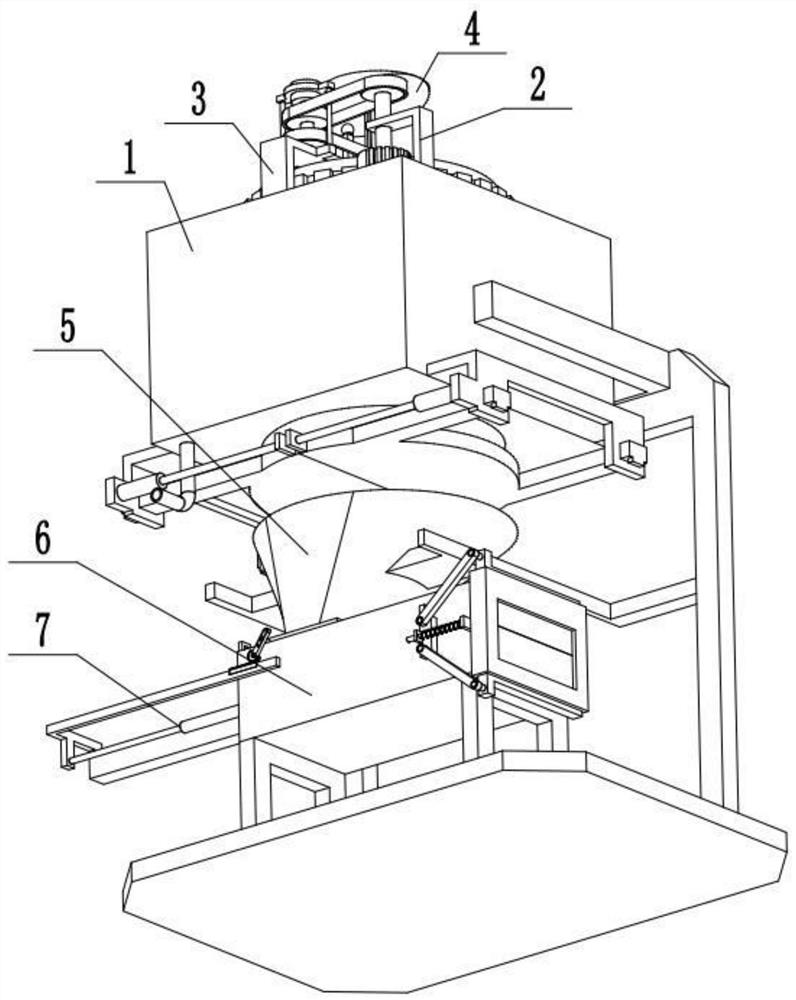

[0034] Combine below Figure 1-14 Describe this embodiment, a pollution-free crushing device for medical waste, including an outer box assembly 1, a waste dehydration mechanism 2, a crushing drive 3, a crushing mechanism 4, a material guide seat 5, a compression box assembly 6, and an extrusion discharge mechanism 7 and the frame 8, the outer box assembly 1, the material guide seat 5 and the compression box assembly 6 are sequentially arranged on the frame 8 from top to bottom, and the garbage dehydration mechanism 2 is arranged on the outer box assembly 1 and the crushing drive 3, the crushing drive 3 is set on the outer box assembly 1, the garbage dehydration mechanism 2 is in transmission connection with the crushing drive 3, the crushing mechanism 4 is movably connected with the crushing drive 3, and the extrusion discharge mechanism 7 is set on the compression box assembly 6 superior. When in use, put the garbage into the garbage dehydration mechanism 2. After the garbag...

specific Embodiment approach 2

[0036] Combine below Figure 1-14 To illustrate this embodiment, the outer box assembly 1 includes a water receiving tank 1-1, a drain pipe 1-2 with a control valve, a bottom plate slide 1-3, a bottom plate 1-4, and an electric telescopic rod 1-5; The upper and lower ends of the water receiving tank 1-1 are open, the garbage dehydration mechanism 2 is arranged on the water receiving tank 1-1, the lower end of the water receiving tank 1-1 is fixedly connected and communicated with the drain pipe 1-2, and the inner bottom surface of the water receiving tank 1-1 Tilting towards the drainpipe 1-2, the two bottom plate slides 1-3 are symmetrically and fixedly connected to the lower end of the water receiving tank 1-1, and the two bottom plates 1-4 are respectively slidingly fitted and connected to the two bottom plate slides 1-3. An electric telescopic rod 1-5 is respectively fixedly connected to the two bottom plate slides 1-3, and the telescopic ends of the two electric telescopi...

specific Embodiment approach 3

[0038] Combine below Figure 1-14 To illustrate this embodiment, the garbage dehydration mechanism 2 includes a motor 2-1, a first pulley 2-2, a second pulley 2-3, a third pulley 2-4, a gear 2-5, and a drive shaft 2 -6, shaft frame plate 2-7, ring gear 2-8 and dehydration cylinder 2-9; the motor 2-1 is fixedly connected to the crushing drive part 3 through the motor frame, and the output shaft of the motor 2-1 is fixedly connected to the first belt The pulley 2-2 and the second pulley 2-3, the second pulley 2-3 is connected with the crushing driving part 3, the first pulley 2-2 is connected with the third pulley 2-4 through a belt transmission, the third pulley The pulley 2-4 and the gear 2-5 are respectively fixedly connected to the two ends of the drive shaft 2-6, the drive shaft 2-6 is rotatably connected to the shaft frame plate 2-7, and the shaft frame plate 2-7 is fixedly connected to the water tank 1-1, the gear 2-5 is meshed with the ring gear 2-8, and the ring gear 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com