Nonlinear process fault identification method and system based on discriminant kernel slow characteristic analysis

A fault identification and slow feature technology, applied in character and pattern recognition, comprehensive factory control, instruments, etc., can solve the problems of not being able to use category label information, not being able to judge fault types, and reducing fault diagnosis performance, so as to improve fault identification performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

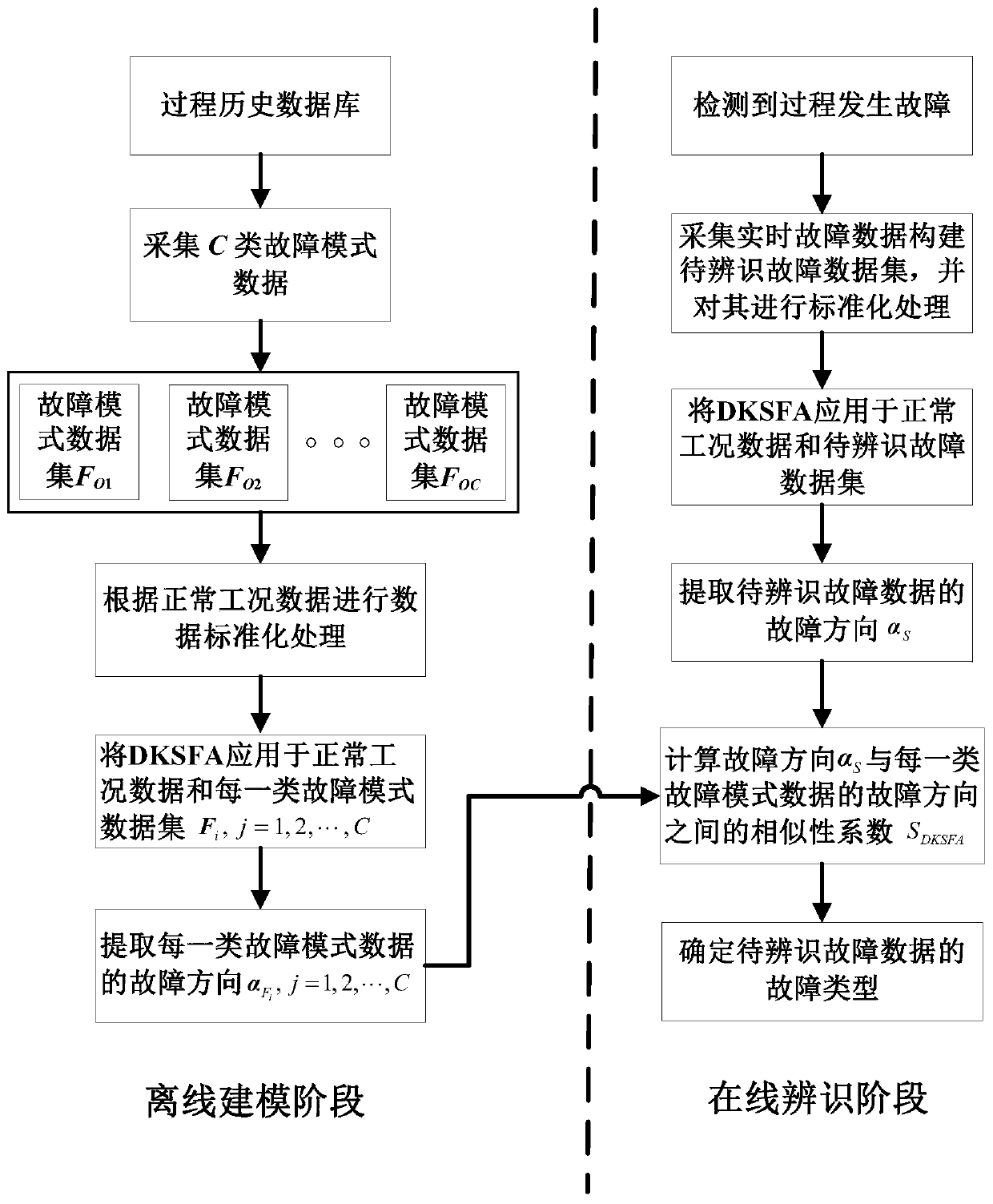

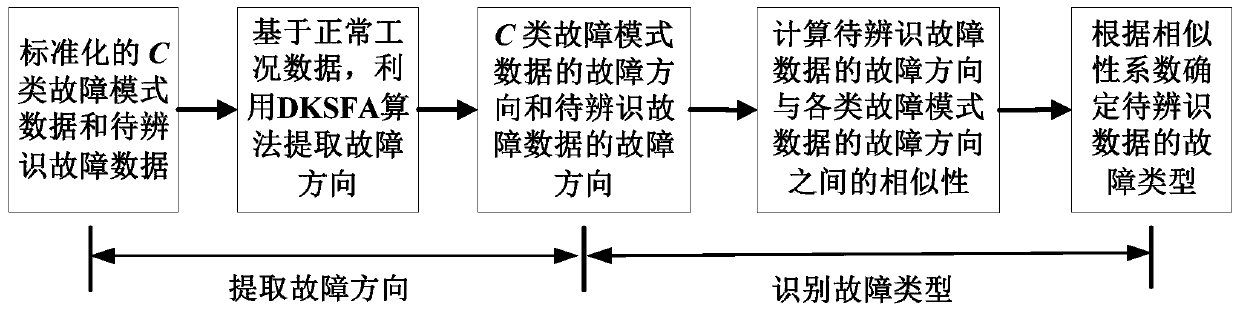

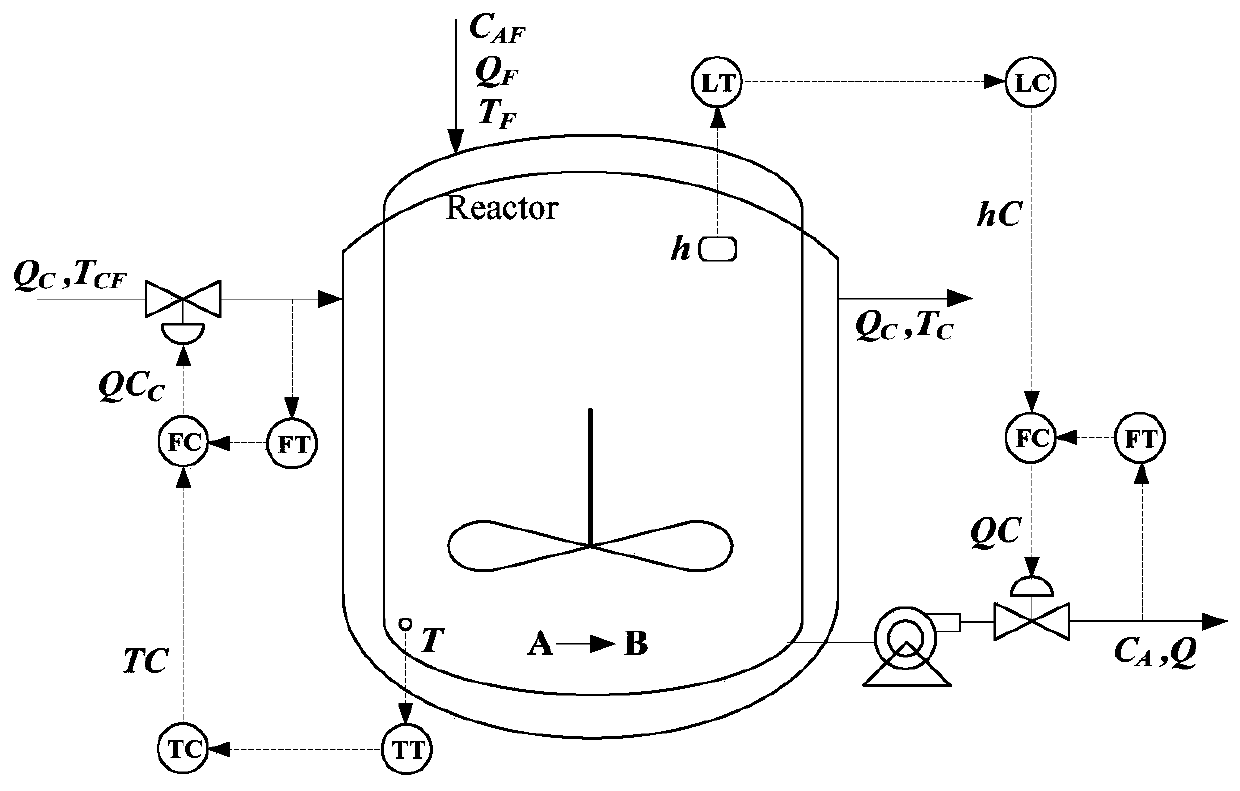

[0031] Such as figure 1 and figure 2 As shown, this embodiment provides a nonlinear process fault identification method based on discriminant kernel slow feature analysis, which includes:

[0032] Step S101: Based on minimizing the time variation of the normal working condition data set and maximizing the inter-class separability between the normal working condition data set and the unidentified fault data set, the unidentified fault data is extracted using the discriminant core slow feature analysis algorithm set and the failure direction of the historical failure mode dataset.

[0033] In the specific implementation, before extracting the fault direction of the fault data set to be identified and the historical fault mode data set, it also includes:

[0034] Receive the normal working condition data set and the historical failure mode data set, standardize the normal working condition data set, standardize the historical failure mode data set according to the normal worki...

Embodiment 2

[0145] This embodiment provides a nonlinear process fault identification system based on discriminant kernel slow feature analysis, which includes:

[0146] (1) Fault direction extraction module, which is used to minimize the time variation of the normal working condition data set and maximize the inter-class separability between the normal working condition data set and the fault data set to be identified, using the discriminant kernel slow The feature analysis algorithm extracts the fault direction of the fault data set to be identified and the historical fault mode data set.

[0147] Specifically, the process of using the discriminant core slow feature analysis algorithm to extract the fault direction of the fault data set to be identified and the historical fault mode data set is as follows:

[0148] Using the discriminant kernel slow feature analysis algorithm to construct the discriminant kernel slow feature analysis objective function, solve the minimization of the disc...

Embodiment 3

[0164] This embodiment provides a computer-readable storage medium, on which a computer program is stored, and when the program is executed by a processor, the figure 1 and figure 2 The steps in the non-linear process fault identification method based on discriminant kernel slow feature analysis are shown.

[0165] This embodiment overcomes the problem that the traditional contribution graph method is prone to "smearing" effect and the limitation that it is not suitable for nonlinear process monitoring methods, and uses the discriminant core slow feature analysis algorithm to extract the fault data set to be identified and the historical fault mode data By calculating the similarity between the fault directions to identify the fault types of the data to be identified, it provides a new idea for identifying the fault types of nonlinear industrial processes based on the discriminant kernel slow feature analysis method, and achieves the goal of using process data. The purpose o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com