Preparation method of high-purity silibinin

A silybin and high-purity technology, which is applied in the field of preparation of high-purity silibinin, can solve the problems that the product is affected by the quality of the crude product, and achieve the effect of method system coordination, less time and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

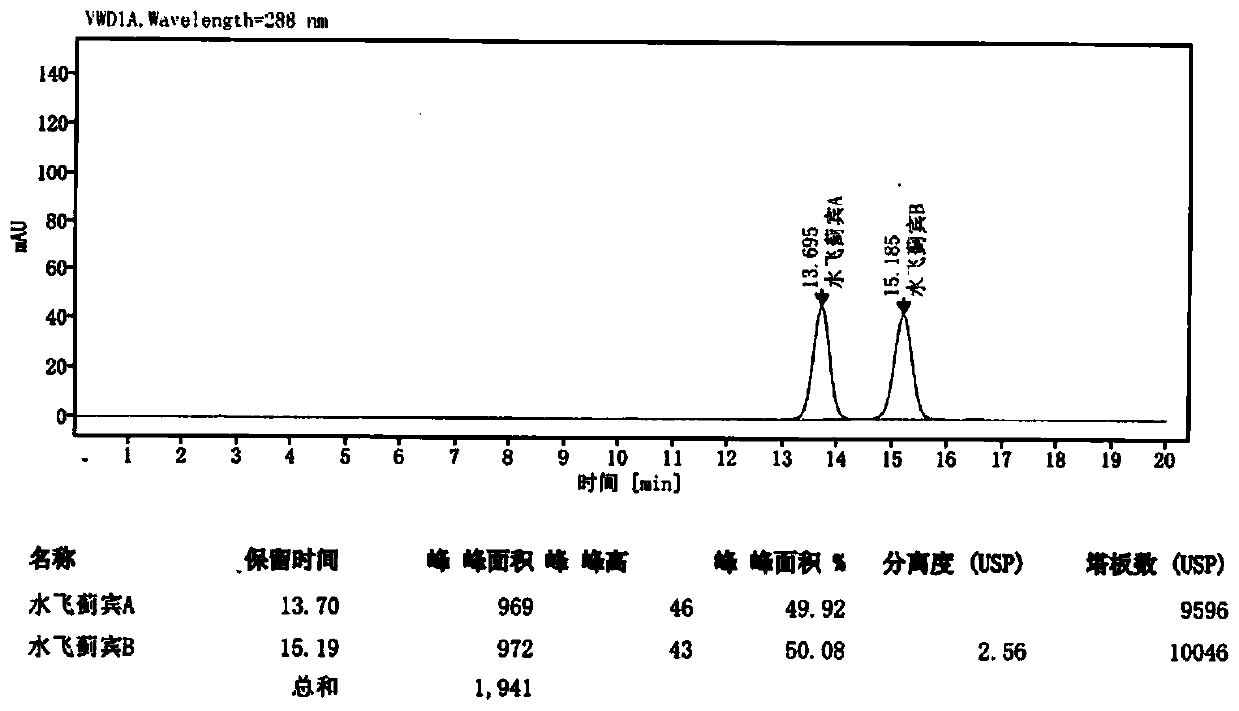

Image

Examples

Embodiment 1

[0034] 1. Superfine pulverization: 30kg of milk thistle is added to a superfine pulverizer for superfine pulverization, and after pulverization, pass through a 120-mesh sieve to obtain pulverized materials.

[0035] 2. Countercurrent extraction: Put the pulverized material into a tank-type countercurrent extraction equipment, heat it to 60°C with 60L ethyl acetate for 2 hours of circulation extraction, and concentrate the extract after extraction to obtain 2.52kg of crude silymarin.

[0036] 3. Recrystallization: Dissolve 2.52kg of crude silymarin in 15L of acetone, stir while heating until completely dissolved, add 0.252kg of activated carbon for decolorization for 0.5h, and cool to obtain silymarin in acetone solution. Add the silymarin solution in acetone to 100L of water, stir well, let it stand, and filter to obtain the wet product of silymarin.

[0037] 4. Drying and pulverization: dry the wet product of silibinin in a vacuum drying oven, and then pulverize it to obtain ...

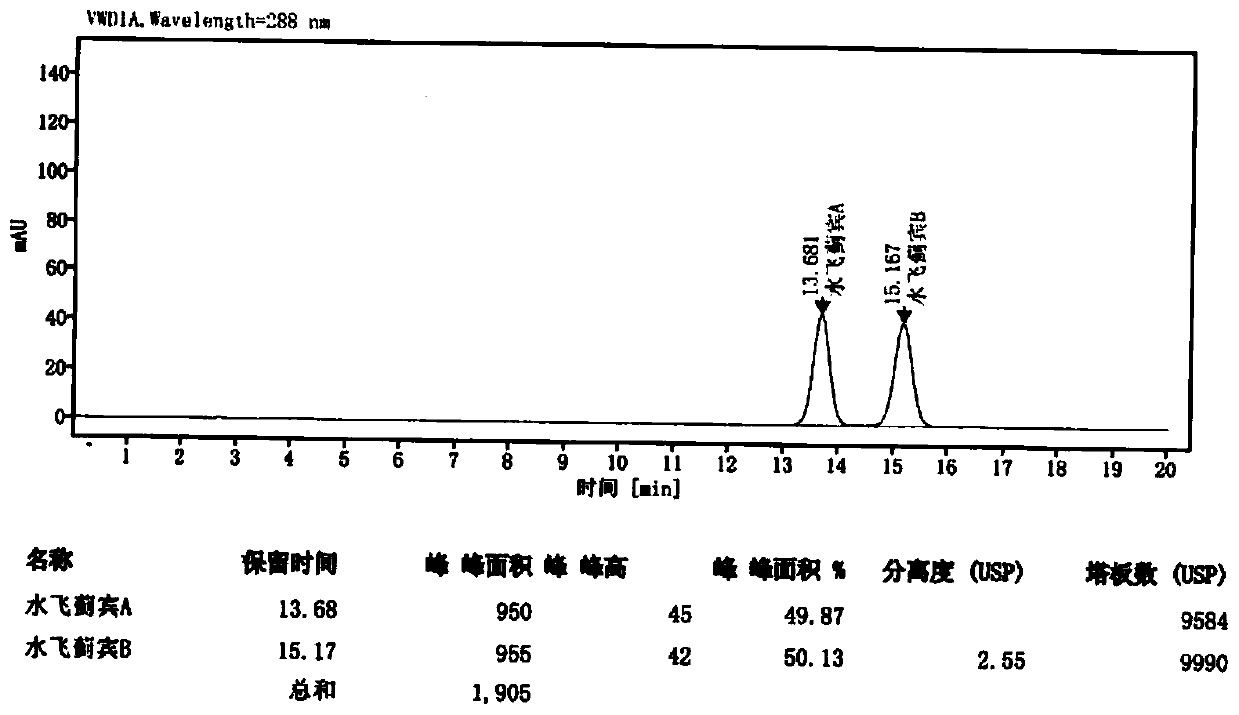

Embodiment 2

[0039] 1. Superfine pulverization: 30kg of milk thistle is added to a superfine pulverizer for superfine pulverization. After pulverization, pass through a 70-mesh sieve to obtain pulverized materials.

[0040] 2. Countercurrent extraction: put the pulverized material into the tank-type countercurrent extraction equipment, use 45L of ethyl acetate to heat to 80°C for 3 hours of circulation extraction, after extraction, concentrate the extract to obtain 2.46kg of crude silymarin.

[0041] 3. Recrystallization: Dissolve 2.46 kg of crude silymarin in 17 L of acetone, stir while heating until completely dissolved, add 0.492 kg of activated carbon for decolorization for 0.5 h, and cool to obtain a solution of silymarin in acetone. The silymarin acetone solution was added to 102L of water, fully stirred, allowed to stand, and filtered to obtain a wet product of silymarin.

[0042] 4. Drying and pulverization: dry the wet product of silibinin in a vacuum drying oven, and then pulveri...

Embodiment 3

[0044] 1. Superfine pulverization: 30kg of milk thistle is added to a superfine pulverizer for superfine pulverization, and after pulverization, pass through a 120-mesh sieve to obtain pulverized materials.

[0045] 2. Countercurrent extraction: put the pulverized material into a tank-type countercurrent extraction equipment, use 75L of ethyl acetate to heat to 50°C for cyclic extraction for 1 hour, and concentrate the extract after extraction to obtain 2.54kg of crude silymarin.

[0046] 3. Recrystallization: Dissolve 2.54 kg of crude silymarin in 13 L of acetone, stir while heating until completely dissolved, add 0.254 kg of activated carbon for decolorization for 1 hour, and cool to obtain a solution of silymarin in acetone. The silymarin acetone solution was added to 104L of water, fully stirred, allowed to stand, and filtered to obtain a wet product of silymarin.

[0047] 4. Drying and pulverization: dry the wet product of silibinin in a vacuum drying oven, and then pulve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com