Manufacturing method of reinforced wing rail alloy steel frog

A production method and technology of alloy steel, which can be applied in the direction of track, switch, road, etc., and can solve the problems of different wear, impact, uneven frog top surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

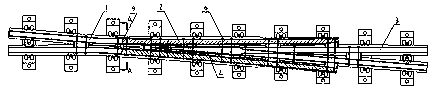

[0018] Embodiment 1: This strengthened wing-rail alloy steel composite frog is mainly composed of alloy steel core rail 4, fork heel rail 3 connected to the rear end of the core rail, and wing rails distributed on both sides of the core rail, through spacer iron 5 and high-strength bolts Connectors 6 are combined together, such as figure 1 shown.

[0019] The wing rail is a fully forged high manganese steel wing rail or a semi-forged high manganese steel wing rail. The semi-forged high manganese steel wing rail is composed of two sections, which are welded by a section of standard cross-section ordinary rail 1 and a section of forged high manganese steel rail 2. As a result, the ordinary rail 1 and a section of forged high manganese steel rail 2 are welded by flash welding, and there is only one weld 9. Ordinary rail 1 is made of the same rail material as section line, which can be used for seamless lines and is convenient for welding.

[0020] After the welded wing rail is ...

Embodiment 2

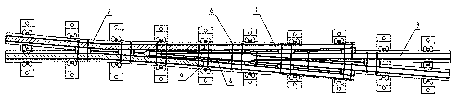

[0022] Embodiment 2: This strengthened wing-rail alloy steel composite frog is mainly composed of alloy steel core rail 4, fork heel rail 3 connected to the rear end of the core rail, and wing rails distributed on both sides of the core rail, through spacer iron 5 and high-strength bolts Connectors 6 are combined together, such as figure 1 , figure 2 shown.

[0023] The wing rail is a two-section welded structure, which is welded by a section of standard cross-section ordinary rail 1 and a section of alloy steel rail 2 , with only one weld 9 . Wing rail alloy steel rail 2 is made of the same alloy steel material as core rail 4 or an alloy steel material with similar properties; The two ends are processed into a standard rail section and connected with the standard rail.

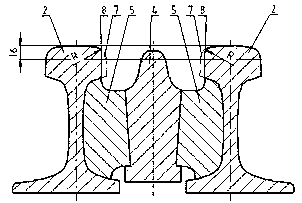

[0024] After the welded wing rail is welded, it is processed according to the designed wing rail structure, and the working edge 7 and fillet 8 of the wing rail are obtained, which smoothly transition wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com