Collecting device for biomass fuel

A biomass fuel and collection device technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of waste of resources, physical injury of staff, etc., and achieve the effect of convenient unloading work, convenient transportation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

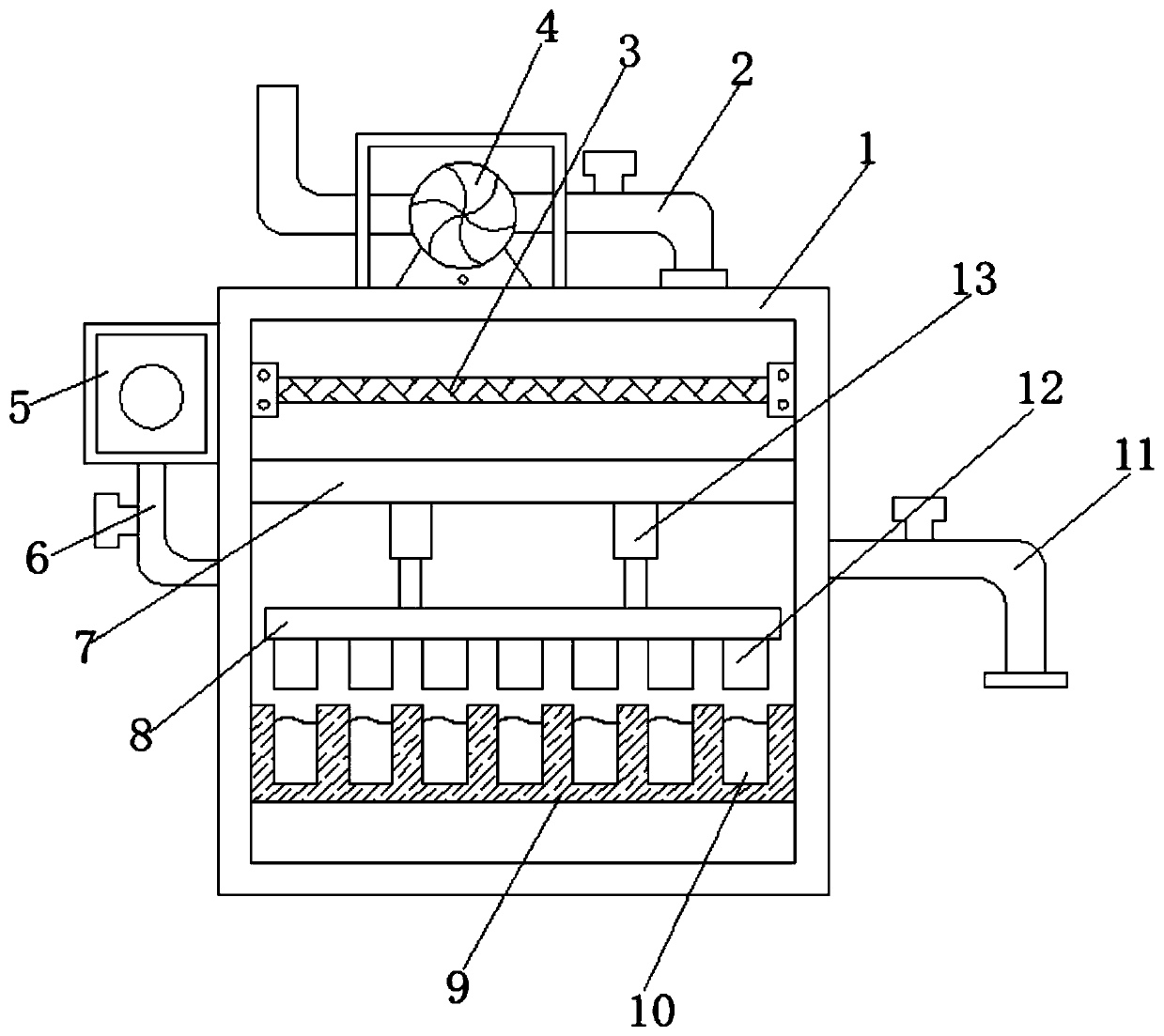

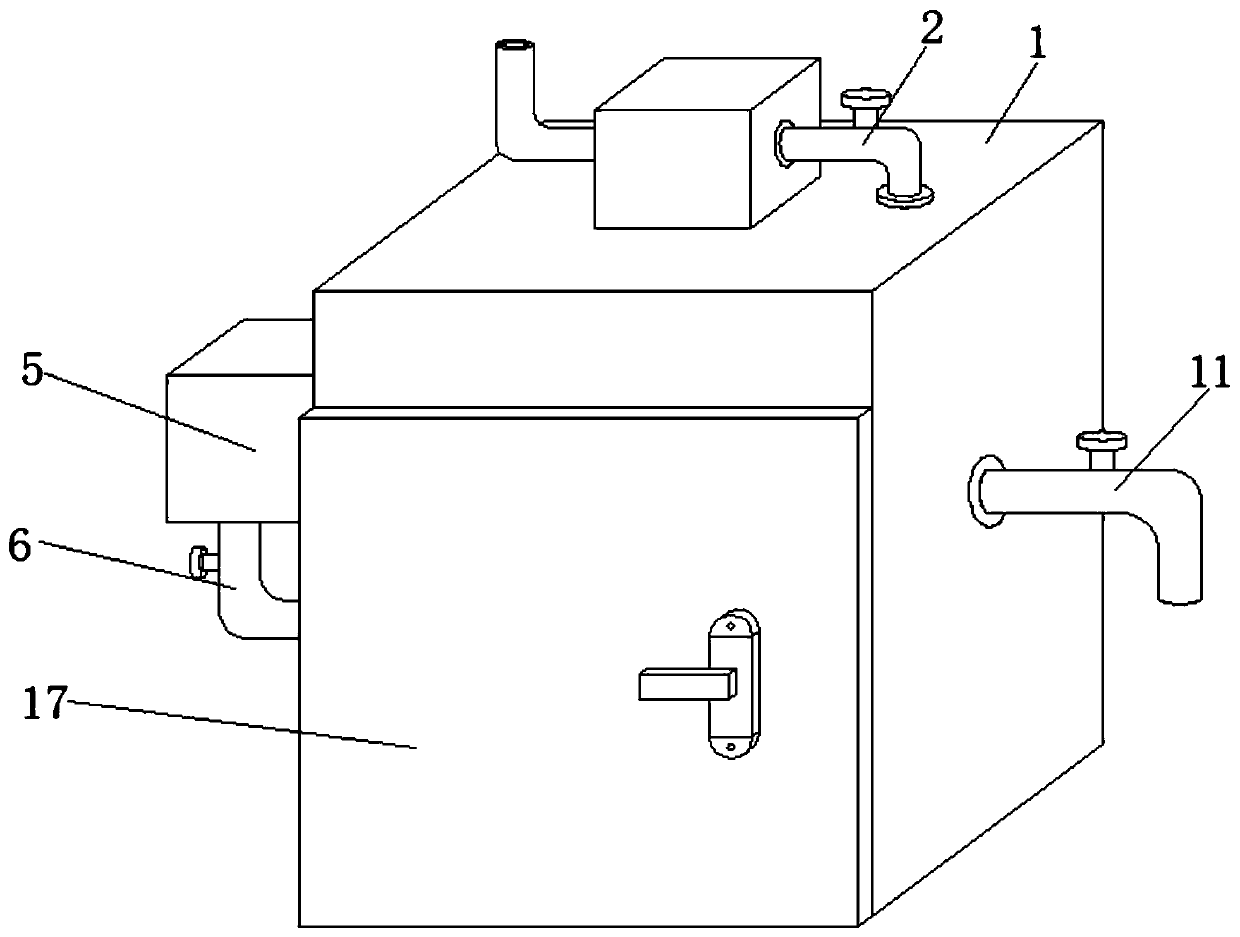

[0025] refer to Figure 1-2 , a collection device for biomass fuel, comprising a box body 1, a connecting pipe 11 is plugged into the outer wall of one side of the box body 1, and an exhaust fan 4 is connected to the top outer wall of the box body 1 by bolts, and one side of the exhaust fan 4 The outer wall is plugged with a suction pipe 2, and the end of the suction pipe 2 away from the exhaust fan 4 extends to the inside of the box body 1, and the inner walls of both sides of the box body 1 are connected with dust filter bags 3 by bolts, and one part of the box body 1 The side outer wall is connected with a hot air blower 5 by bolts, and an air inlet pipe 6 is plugged into one side of the outer wall of the hot air blower 5 , and the end of the air inlet pipe 6 away from the hot air blower 5 extends to the inside of the box body 1 .

[0026] Wherein, the inner walls on both sides of the box body 1 are connected with the fixed rod 7 by bolts, and the bottom outer wall of the f...

Embodiment 2

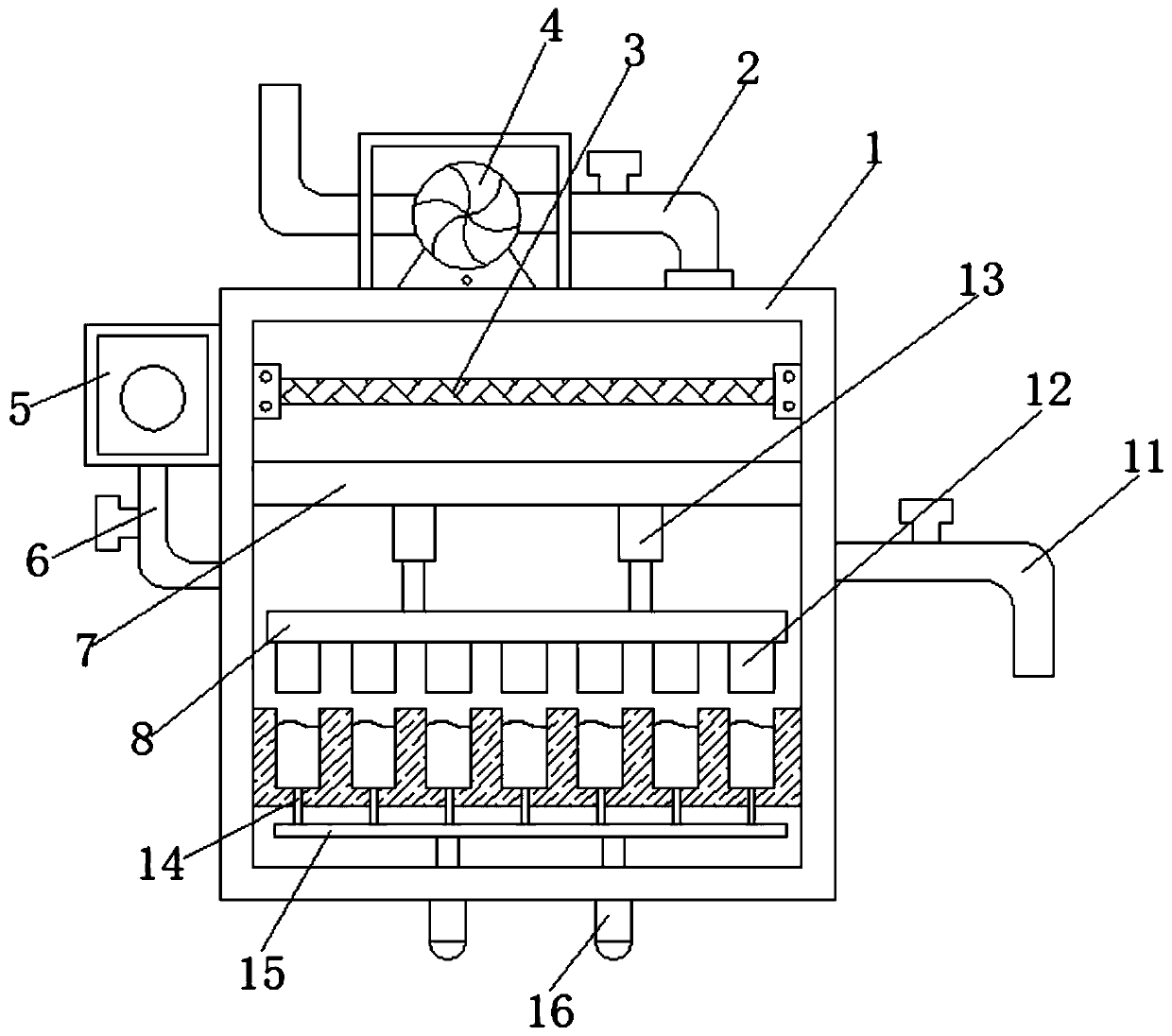

[0029] refer to image 3 , a collection device for biomass fuel. Compared with Embodiment 1, the outer wall of the bottom of the box body 1 is inserted with a second electric push rod 16, and one end of the outer wall of the second electric push rod 16 is connected by bolts. The second connecting rod 15, the top outer wall of the second connecting rod 15 is welded with a fixing column 14, and the bottom outer wall of the pressure groove 10 has a circular hole, and one end of the fixing column 14 extends into the circular hole.

[0030] Working principle: When in use, the staff inserts the connecting pipe 11 into the pulverizer, and then starts the exhaust fan 4, and the exhaust fan 4 can suck the debris generated during the crushing process into the box body 1 through the connecting pipe 11, which can effectively The debris is collected to avoid the direct discharge of the debris and cause harm to the body of the staff. When the debris collected in the box 1 falls into the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com