Artificial aggregate and preparation method thereof

An artificial bone and artificial technology, applied in the field of solid waste reuse, can solve the problems of large land occupation, low utilization rate, polluted land, rivers and lakes, etc., and achieve the effects of saving steel bars, low water absorption and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Prepare the mixture:

[0034] Put 250 parts of foundry regeneration ash, 250 parts of foundry dedusting ash and 50 parts of Ca-based bentonite ball-milled into 150-mesh raw materials into a mixer and stir for 10 minutes;

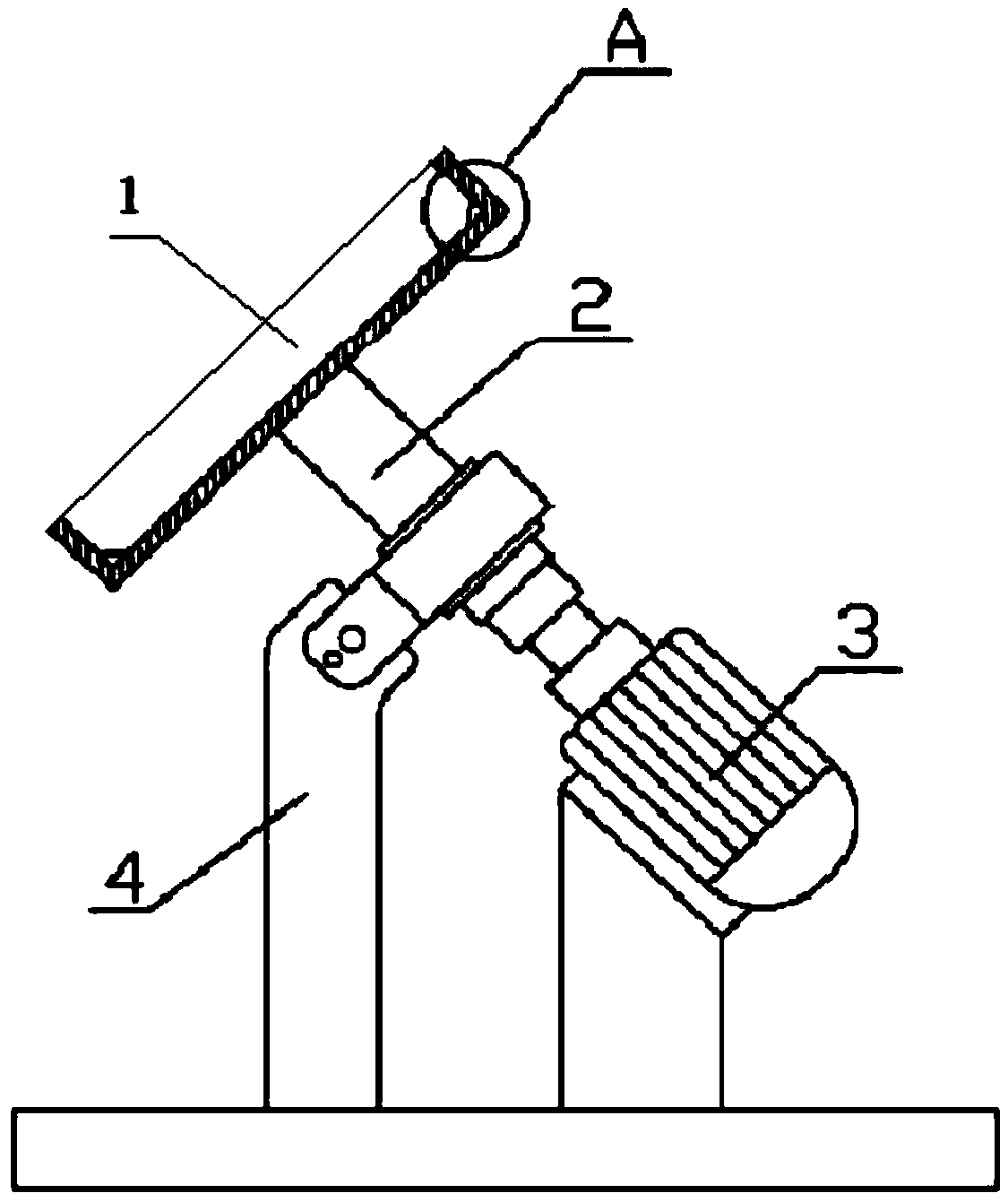

[0035] (2) Granulation and maintenance:

[0036] Granulate the mixed powder in a disc granulator with a rotating speed of 35r / min to obtain pellets with a particle size of 5mm, and then maintain them in a thermostat at 120°C for 24 hours;

[0037] (3) Sintering:

[0038] The artificial aggregate was obtained by sintering at 1125° C. for 30 minutes.

Embodiment 2

[0040] (1) Prepare the mixture:

[0041] Put 250 parts of foundry regenerated ash, 250 parts of foundry dedusting ash, 50 parts of Ca-based bentonite, and 50 parts of fly ash into 100 mesh particle size, put them into the mixer and stir for 5 minutes;

[0042] (2) Granulation and maintenance:

[0043] Granulate the mixed powder in a disc granulator with a rotating speed of 30r / min to obtain pellets with a particle size of 3mm, and then maintain them in a thermostat at 120°C for 24 hours;

[0044] (3) Sintering:

[0045] The artificial aggregate was obtained by sintering at 1150° C. for 30 minutes.

Embodiment 3

[0047] (1) Prepare the mixture:

[0048] Put 250 parts of foundry regenerated ash, 250 parts of foundry dedusting ash, 75 parts of Ca-based bentonite and 75 parts of fly ash into 150 mesh particle size and put them into the mixer and stir for 15 minutes;

[0049] (2) Granulation and maintenance:

[0050] Granulate the mixed powder in a disc granulator with a rotating speed of 40r / min to obtain pellets with a particle size of 8mm, and then maintain them in a thermostat at 120°C for 24 hours;

[0051] (3) Sintering:

[0052] The artificial aggregate was obtained by sintering at 1150° C. for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com