Ultrasonic wave environment purifier

An ultrasonic and purifier technology, applied in the field of purification equipment, can solve the problems of fire caused by static electricity, machine damage, failure to apply, etc., and achieve the effect of high purification efficiency and good cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

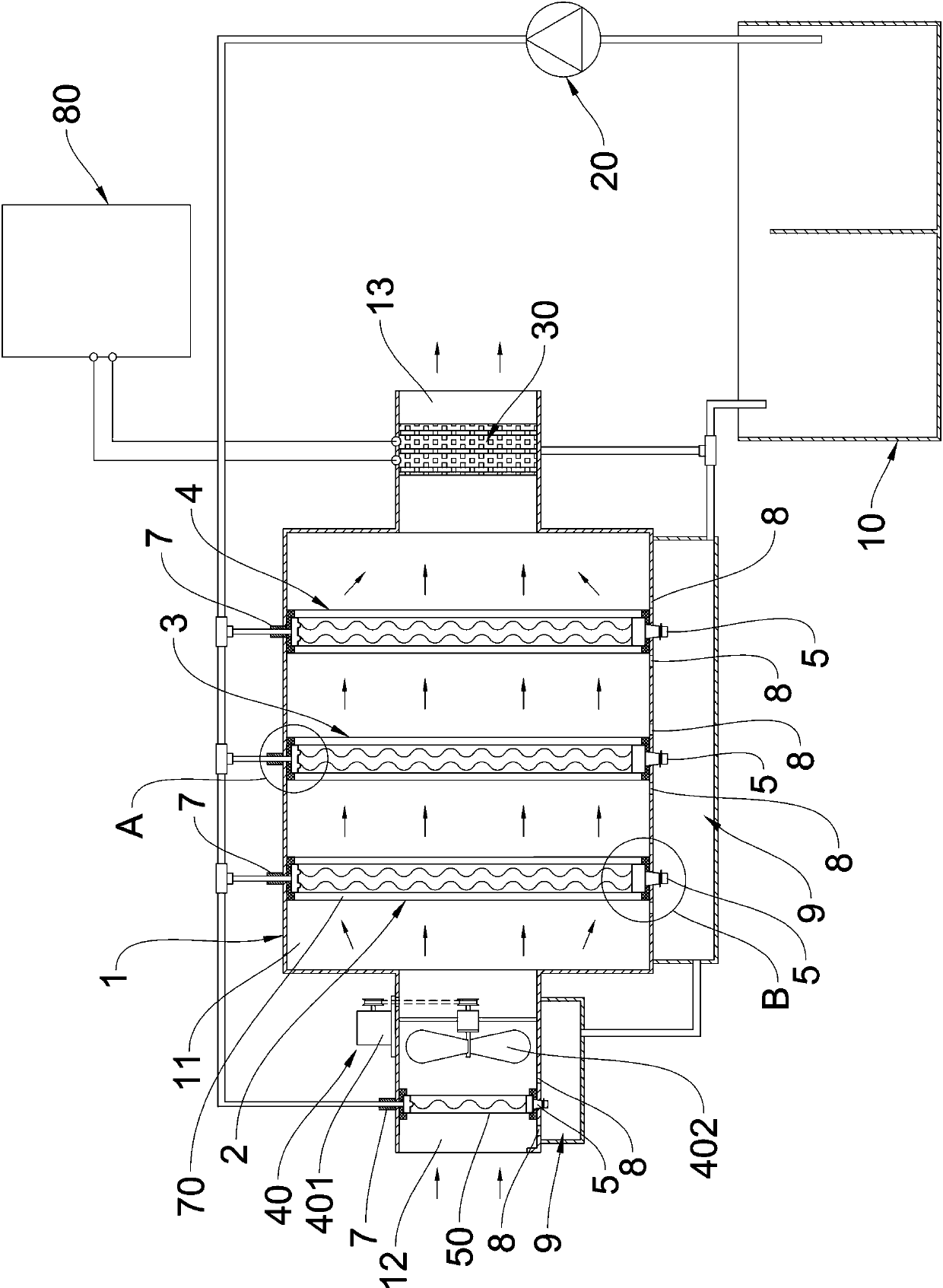

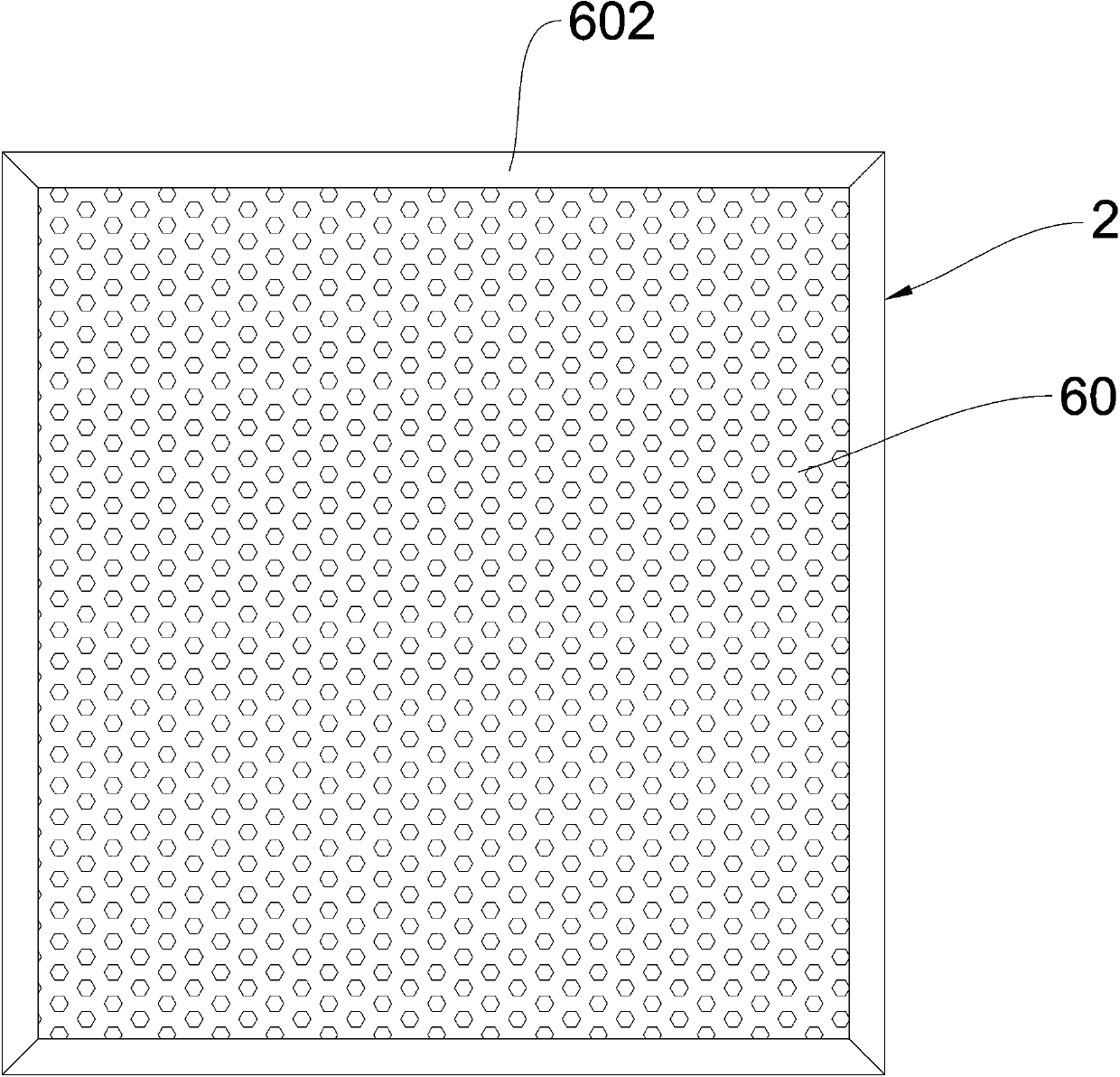

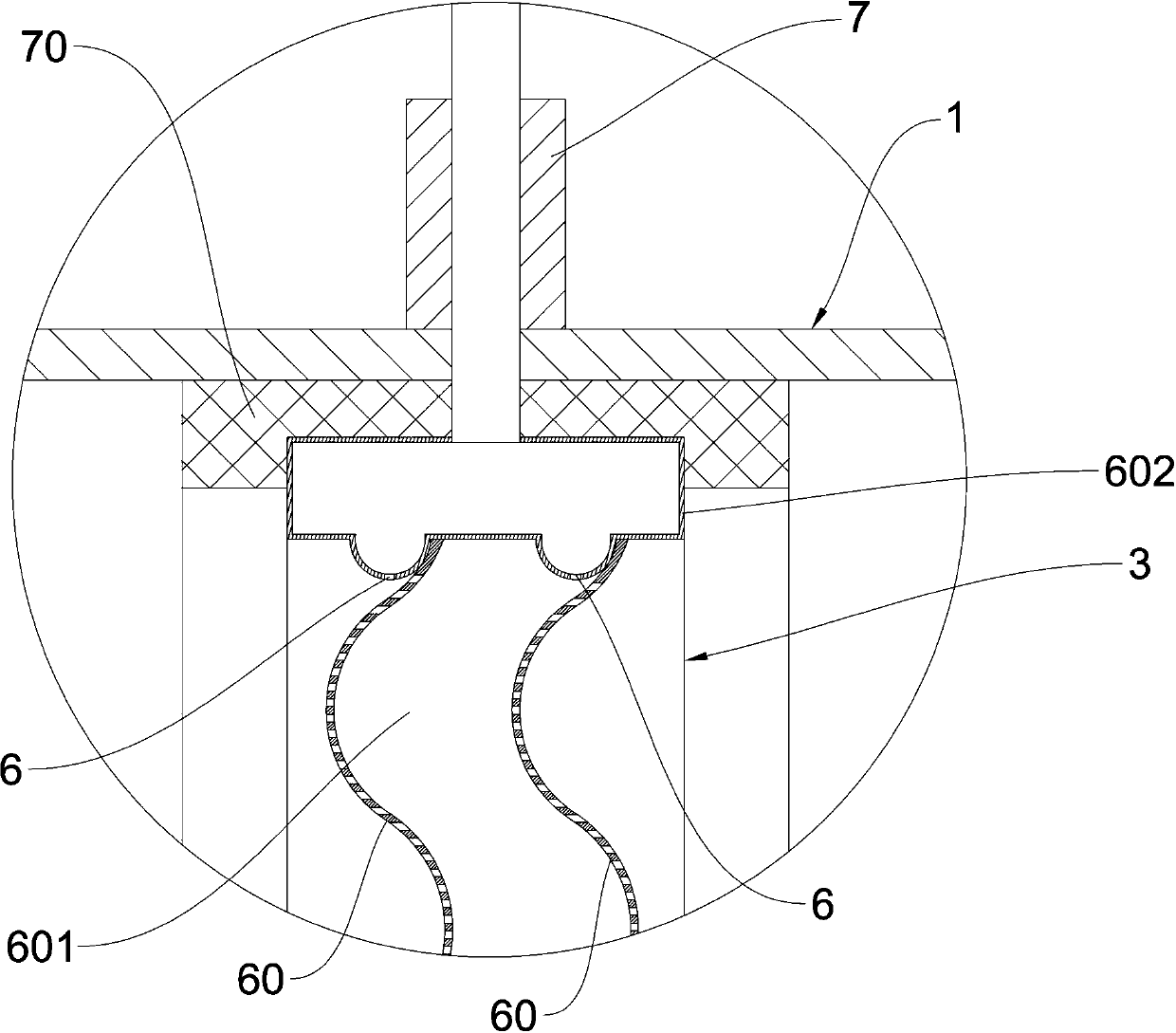

[0012] Such as figure 1 As shown, a kind of ultrasonic environment purifier of the present invention comprises casing 1, at least one filter screen board, ultrasonic transducer 5, wherein said casing 1 is provided with purification chamber 11, in casing 1 The two ends are respectively provided with an air inlet 12 and an air outlet 13, and the air inlet 12 and the air outlet 13 communicate with the purification chamber 11 respectively. In application, the air inlet 12 is generally connected with the air outlet of the fan or the source of turbid air to filter and purify the turbid air.

[0013] Such as figure 1 As shown, each filter screen plate is vertically installed in the purification chamber 11 respectively in sequence, and ultrasonic transducers 5 are also respectively arranged on the sides of each filter screen plate, so that each filter screen plate generates ultra-high Frequency cut oscillating filter motion. The ultrasonic transducer 5 is arranged at any position a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com