Tool track interpolation and speed planning method based on machine tool vibration suppression

A technology of vibration suppression and tool trajectory, applied in the field of CNC machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0173] In this embodiment, a tool trajectory interpolation and speed planning method based on machine tool vibration suppression is described, and the specific steps are as follows:

[0174] (1) Step 1, read the G01 track point into the memory of the numerical control system.

[0175] (2) Step 2, for the G01 trajectory segment obtained in step 1, design G that satisfies the chord error constraint 4 Continuous interpolation trajectory, the specific operation method is as follows:

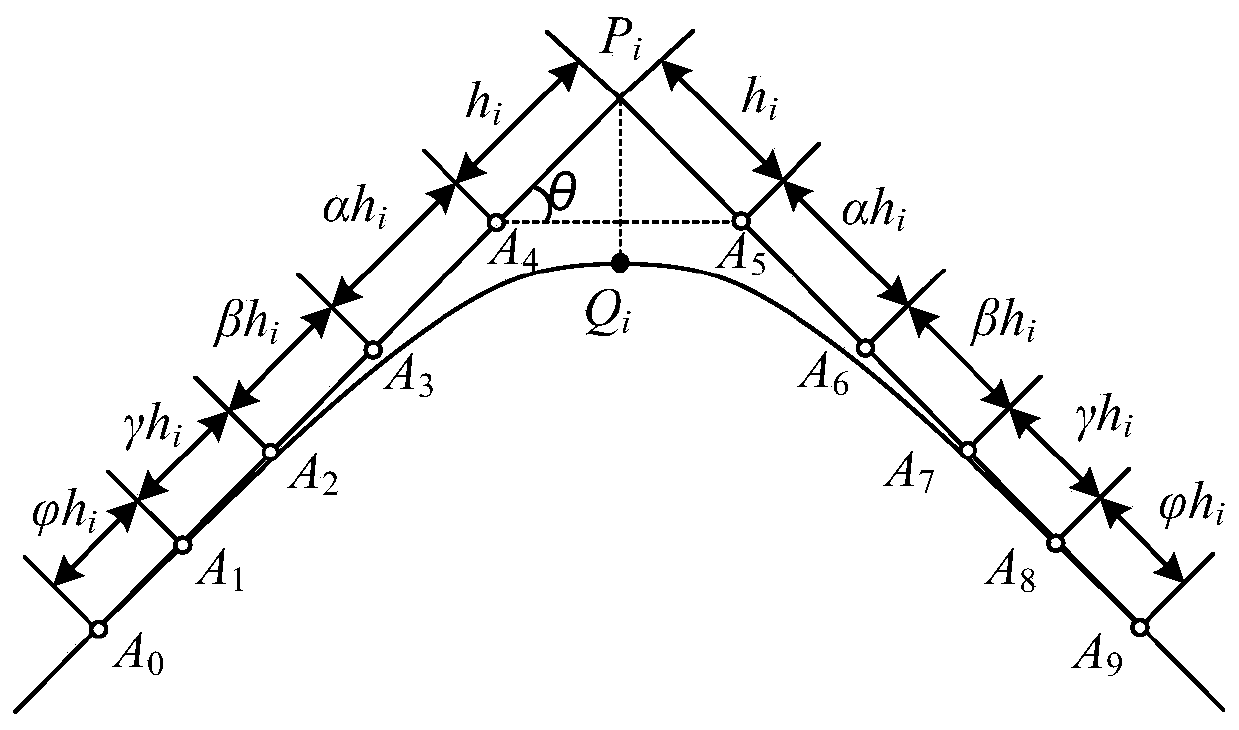

[0176] Step 2-1, establish G at the corner of the G01 trajectory 4 Geometric Model of Continuous Transition Curves

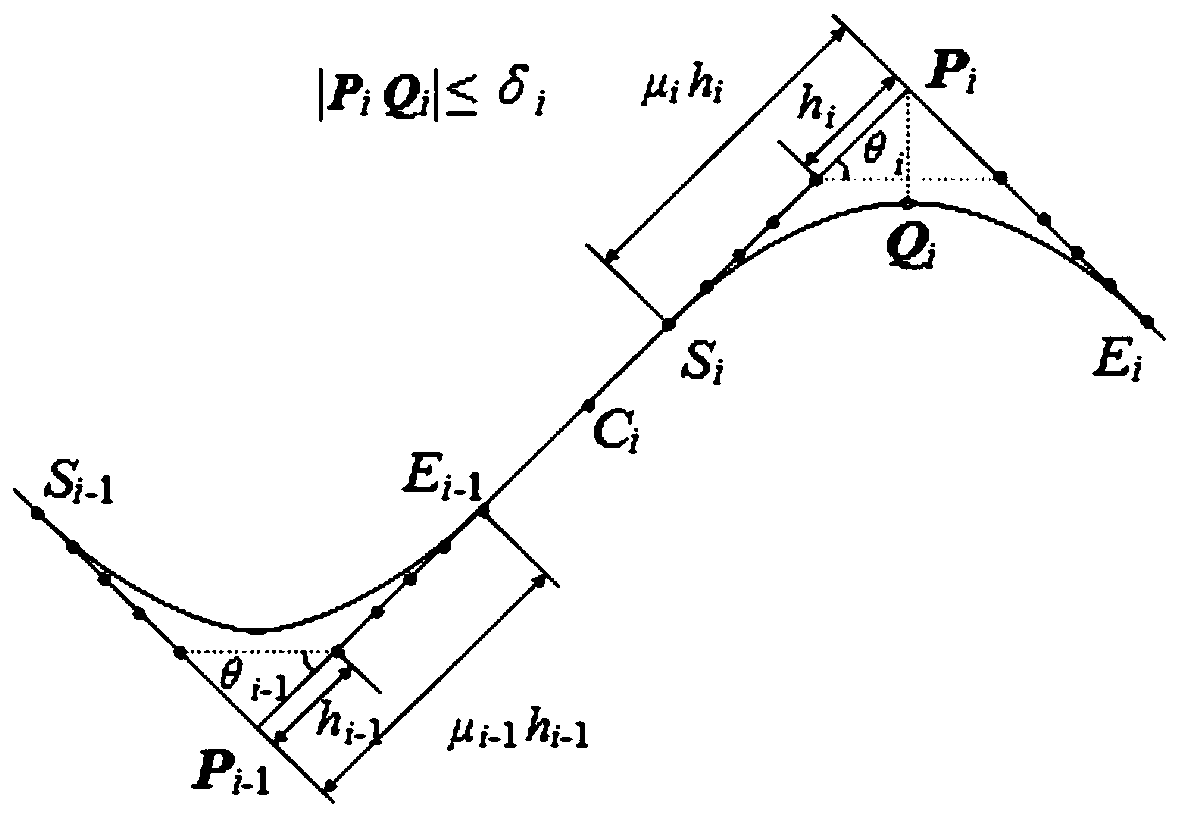

[0177] Trajectory corner P i-1 P i P i+1 The transition curve at is composed of symmetrical nine-degree Bezier curves, such as figure 1 As shown, the mathematical form of the transition curve is shown in formula 1:

[0178]

[0179] In formula (1) A i represents a control point that satisfies where α, β, γ, is the control point ratio (CPR), and the value of the contr...

Embodiment 2

[0308] Based on a tool trajectory interpolation and speed planning method based on machine tool vibration suppression provided in Embodiment 1, specific application cases are shown in the following three links:

[0309] (1) The trajectory point of the "dolphin" model {P i} i=0…219 Read into the memory of the CNC system, the G01 track point of the model is as follows Figure 6 shown;

[0310] (2) Read the G01 trajectory segment from the memory {P i} i=0…219 , design G that satisfies the chordal error constraint 4 Continuously interpolated trajectories. Let the chord error constraint of the trajectory be δ=0.04mm, and the calculation accuracy be ε=10 -4 mm, use the algorithm InterG4 provided in steps 2-4 to calculate the G of the "dolphin" model 4 Continuous interpolation trajectory, the trajectory curve generated by 4 iterations is recorded as: Determine {P according to formula (2) i (4)} The CPR value at each corner of the sequence, calculated according to the CPR v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com