Liquid heater

A liquid heater and bottle technology, applied in the field of household electrical appliances, can solve problems such as the inability to accurately determine the height of the liquid heater, the inability to pump out water, and the breeding of bacteria to achieve the effect of reducing hot water splashing and reducing the risk of burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

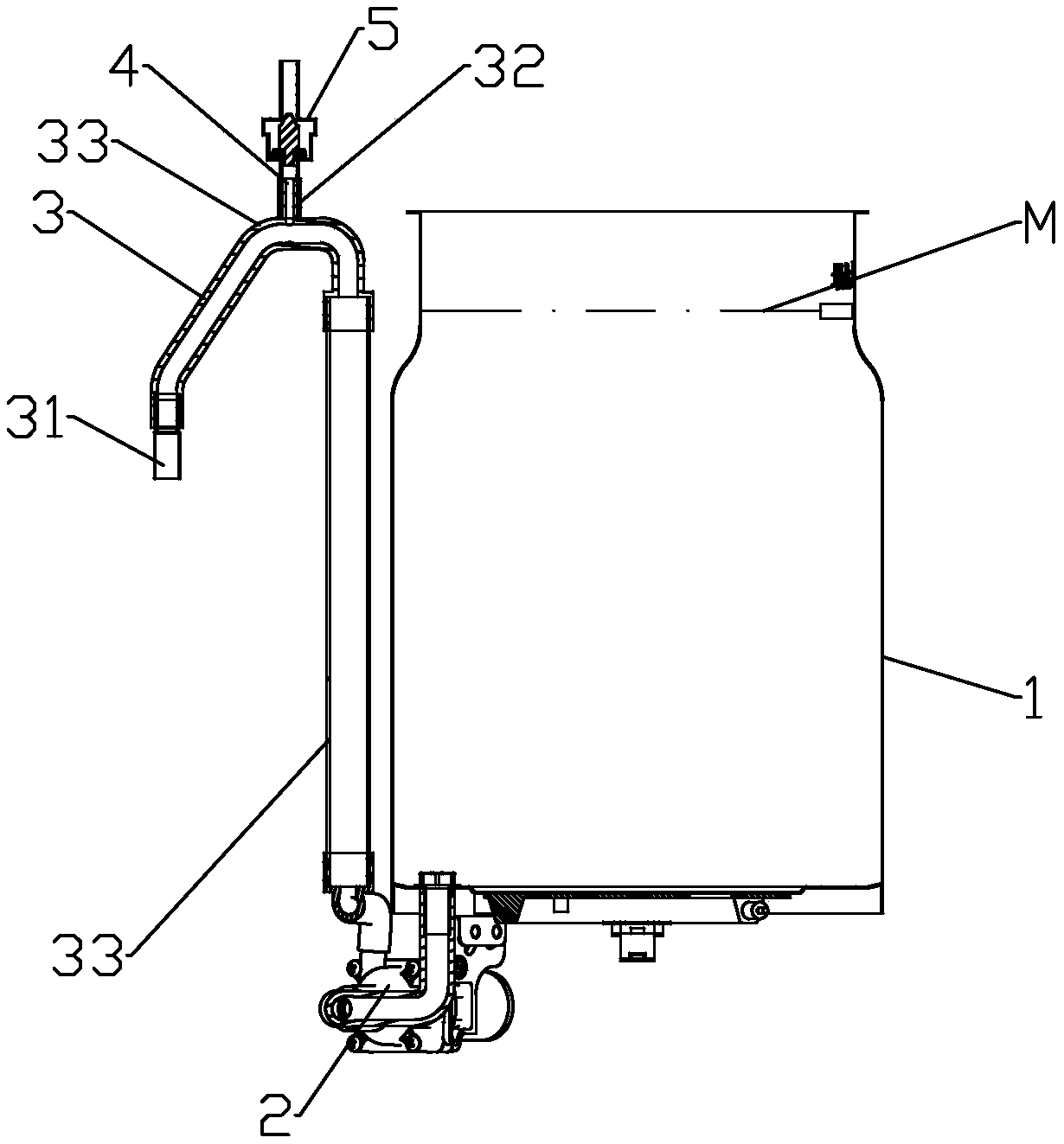

[0023] The present invention provides a liquid heater. In this embodiment, the liquid heater is an electric hot water bottle as an example, including a bottle body and an inner liner 1, a water pump 2 and a water outlet pipe 3 arranged on the bottle body, such as figure 1 As shown, the water pump 2 is connected to the inner tank 1. One end of the water outlet pipe 3 is connected to the water pump 2, and the other end is provided with a water outlet 31. The water outlet pipe 3 extends to a position above the rated maximum water level of the inner tank 1 and the height of the water outlet 31. Below the rated maximum water level M of the inner tank 1, an anti-siphon passage 4 is provided on the outlet pipe 3, and air enters the outlet pipe 3 through the anti-siphon passage 4 when the water pump 2 is stopped to prevent siphoning. First of all, after lowering the height of the water outlet 31, it can be closer to the container receiving water, reducing the splashing of hot water and r...

Embodiment 2

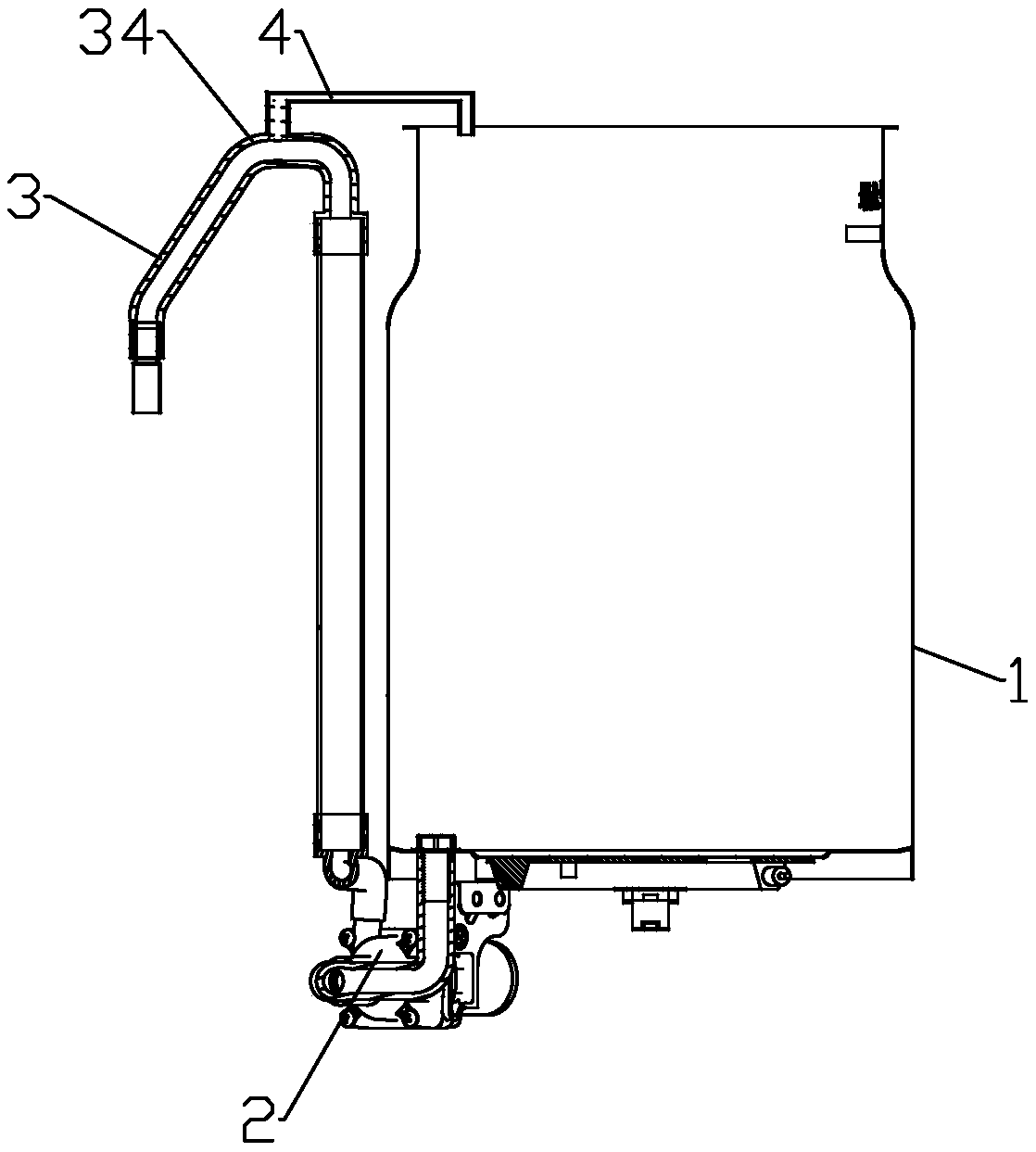

[0029] In addition to using a one-way valve or solenoid valve, it is also possible to design the inlet end of the anti-siphon passage 4 to be high enough relative to the top of the outlet pipe 3, and the water pump 2 is not enough to let water spray out from the anti-siphon passage 4, and the anti-siphon passage 4 Partly or completely higher than the height of the curved section 34, such as figure 2 As shown, all the anti-siphon passages 4 are higher than the height of the curved section 34. One end of the anti-siphon channel 4 is in the best communication with the curved section 34, and air can be fed into the water outlet pipe 3 in time when the water pump 2 stops working, and the siphon phenomenon can be quickly prevented from occurring.

[0030] The other end of the anti-siphon passage 4 may be located on the top or side of the bottle body or extend into the inner liner 1. In this embodiment, the other end of the anti-siphon channel 4 extends into the inner tank 1. Once an a...

Embodiment 3

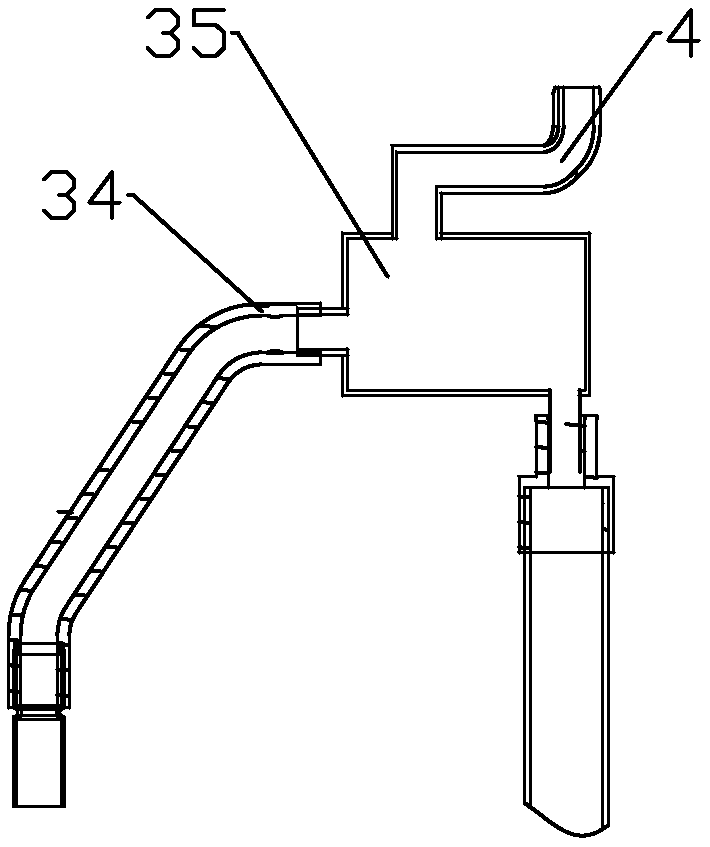

[0033] In order to avoid setting the other end of the anti-siphon channel 4 too high to affect the design of the bottle body, the bending section 34 can be designed to include a water-gas separation cavity 35, such as image 3 As shown, the anti-siphon channel 4 is connected to the top wall of the water-gas separation chamber 35. The water-gas separation cavity 35 can store a certain volume of water, which can effectively prevent water from spraying from the other end of the anti-siphon channel 4.

[0034] For other content not described in this embodiment, reference may be made to the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com