Hot dry rock single well closed-type development method

A single-well closed-type, hot-dry rock technology, applied in geothermal energy power generation, geothermal energy, mining fluids, etc., can solve the problems of environmental pollution, poor fracturing effect, high fracturing cost, etc., achieve simple construction process and reduce construction cost, and the effect of improving rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

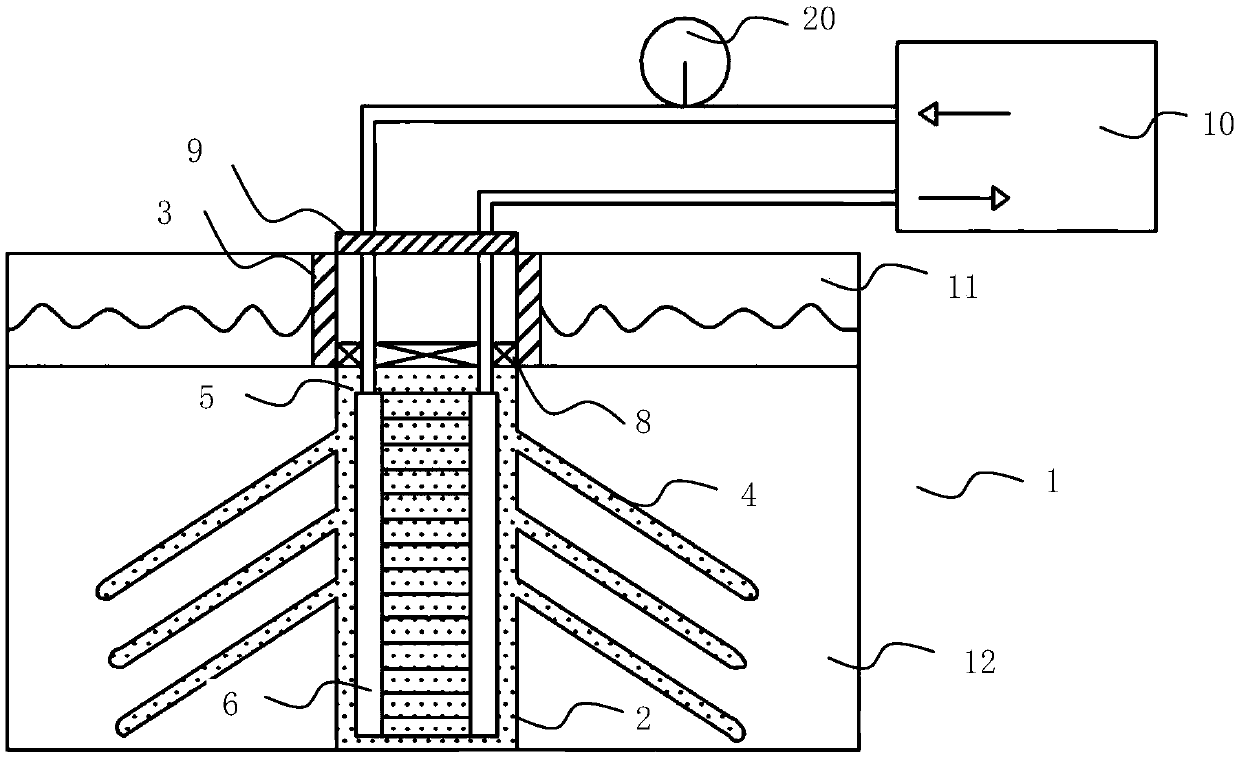

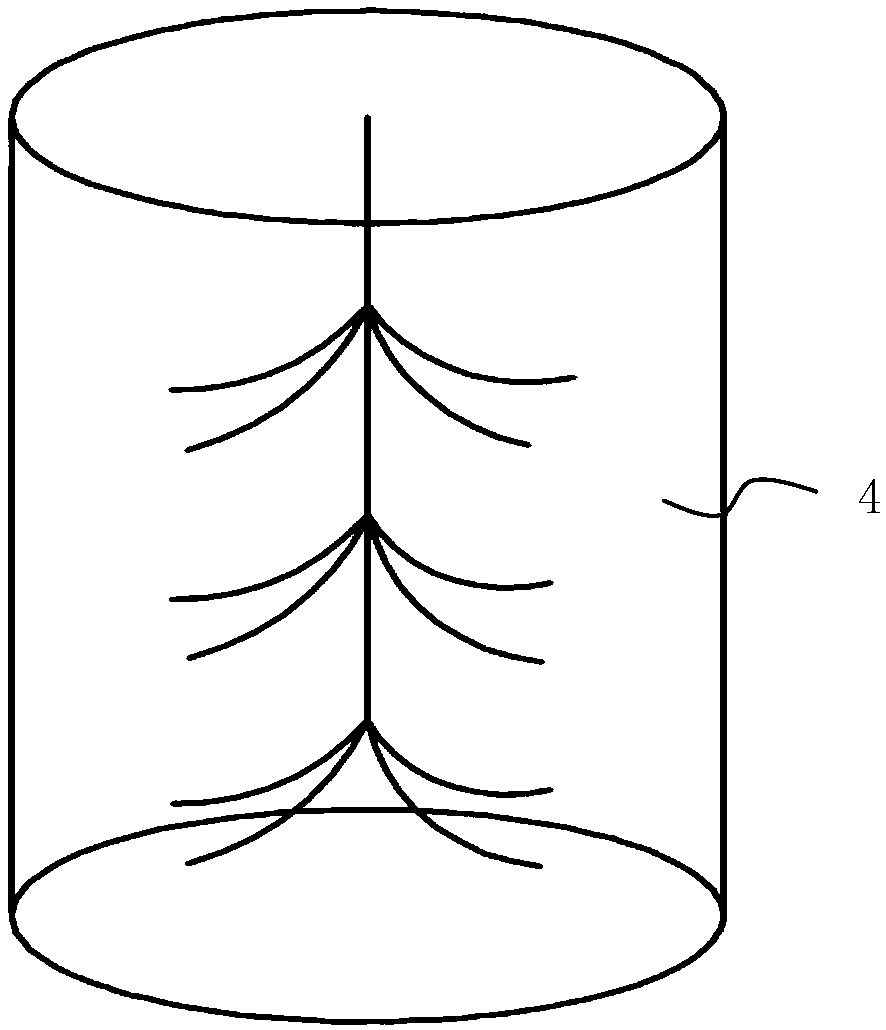

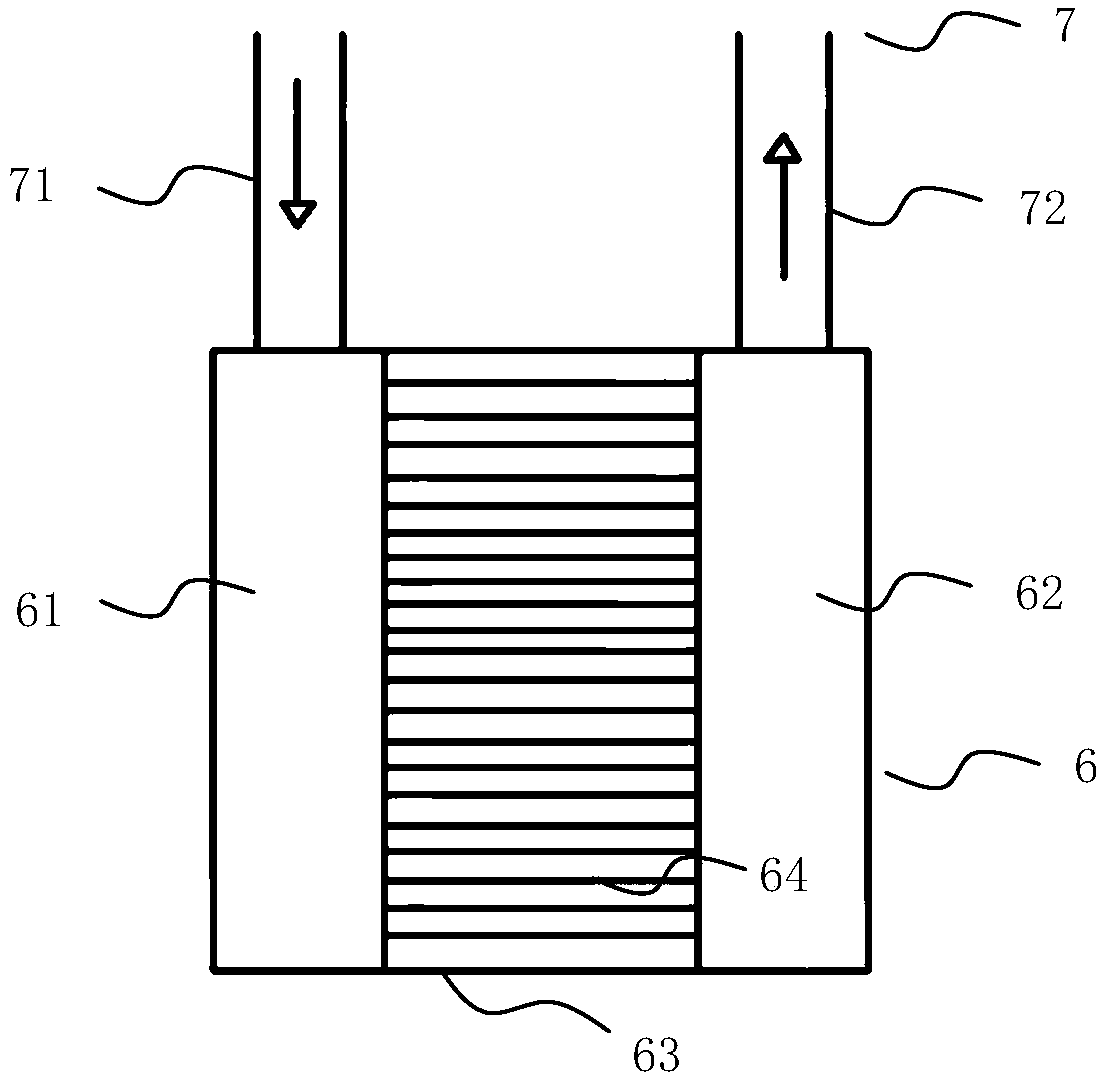

[0048] Such as figure 1 , figure 2 and image 3 As shown, a kind of hot dry rock single well closed cycle heat exchange method of the present invention comprises the following steps:

[0049] Step 1. Determine the burial depth of the hot dry rock, design the drilling project plan, and drill a vertical well in the stratum 1 to form the main borehole 2. The main wellbore 2 in the upper formation 11 of the hot dry rock is cemented with casing 3 and common cement slurry, and the hot dry rock reservoir 12 is completed with a 152.4 mm diameter open hole.

[0050] Step 2. Run the micro-bore branch well drilling device into the bottom of the main wellbore 2 by using the drill pipe. The micro-bore branch well drilling device is composed of three sub-sections with a length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com