Production method of high-quality mango vinegar

A high-quality, mango technology, applied in the preparation of vinegar, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of unguaranteed quality, single flavor of vinegar drink, simple function, etc. Absorption, increased nutrients, increased functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

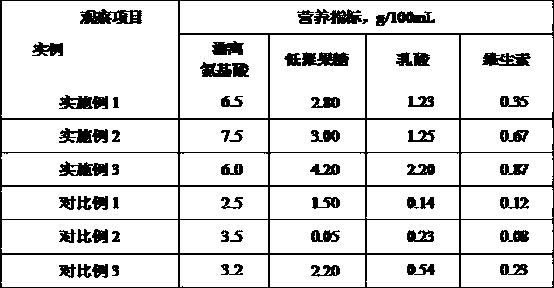

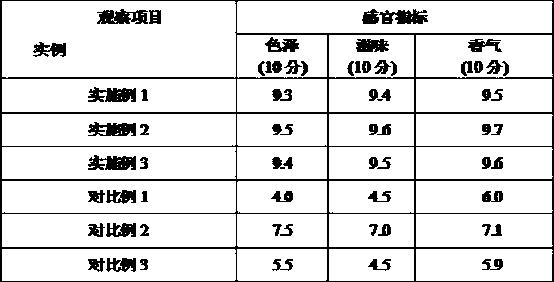

Examples

Embodiment 1

[0034] S1, preparation of mango slurry: Take 600g of fresh mango, wash and cut into pieces, soak in nutrient solution, drain the water, and use colloid mill to refine and beat.

[0035] S2, preparation of mixed fruit and vegetable slurry: Take 200g of fresh Jerusalem artichoke and 200g of pineapple, mix them according to the ratio of 1:1, beat and refine them.

[0036] S3, preparation of mycelia: culture Aspergillus oryzae and Aspergillus niger on liquid medium, wherein the medium of Aspergillus oryzae is mixed with YPG medium and mango juice in a ratio of 1:1, and the medium of Aspergillus niger is potato dextrose liquid culture The ratio of base and mango juice is mixed at 1:1; the conditions for the cultivation of the two bacteria are as follows, the cultivation temperature is 30°C, the initial pH value is 6.0, the rotation speed is 150r / min, and the time is 40h.

[0037] S4, preparation of enzymolysis solution: centrifuge the obtained bacterial suspension to obtain myceliu...

Embodiment 2

[0044] With embodiment 1, the difference is,

[0045] S1, preparation of mango slurry: Take 800g of fresh mango, wash and cut into pieces, soak in nutrient solution, drain the water, and use colloid mill to refine and beat.

[0046] S2, preparation of mixed fruit and vegetable slurry: Take 200g of fresh Jerusalem artichoke and 300g of pineapple, mix them according to the ratio of 1:2, beat and refine them.

[0047] S3, preparation of mycelia: culture Aspergillus oryzae and Aspergillus niger on a liquid medium, wherein the medium of Aspergillus oryzae is a mixture of YPG medium and mango juice in a ratio of 2:1, and the medium of Aspergillus niger is potato dextrose liquid culture Base and mango juice were mixed at a ratio of 2:1; the conditions for the cultivation of the two bacteria were as follows, the cultivation temperature was 32°C, the initial pH value was 7.0, the rotation speed was 180r / min, and the time was 50h.

[0048] S4, preparation of enzymolysis solution: centr...

Embodiment 3

[0055] With embodiment 1, the difference is,

[0056] S1, preparation of mango slurry: Take 1200g of fresh mango, wash and cut into pieces, soak in nutrient solution, drain the water, and use colloid mill to refine and beat.

[0057] S2, preparation of mixed fruit and vegetable slurry: Take 400g of fresh Jerusalem artichoke and 900g of pineapple, mix them according to the ratio of 1:2, beat and refine them.

[0058] S3, preparation of mycelia: culture Aspergillus oryzae and Aspergillus niger on a liquid medium, wherein the medium of Aspergillus oryzae is a mixture of YPG medium and mango juice in a ratio of 2:1, and the medium of Aspergillus niger is potato dextrose liquid culture Base and mango juice were mixed at a ratio of 2:1; the conditions for the cultivation of the two bacteria were as follows, the cultivation temperature was 35°C, the initial pH value was 7.0, the rotation speed was 200r / min, and the time was 60h.

[0059] S4, preparation of enzymatic hydrolysis solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com