Automotive full-automatic protection cover

A fully automatic, protective cover technology, applied in the direction of movable outer sheath, vehicle parts, transportation and packaging, etc., can solve the problems of high labor intensity, complicated operation, complex and bulky structure, etc., to reduce failures and ensure stability. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

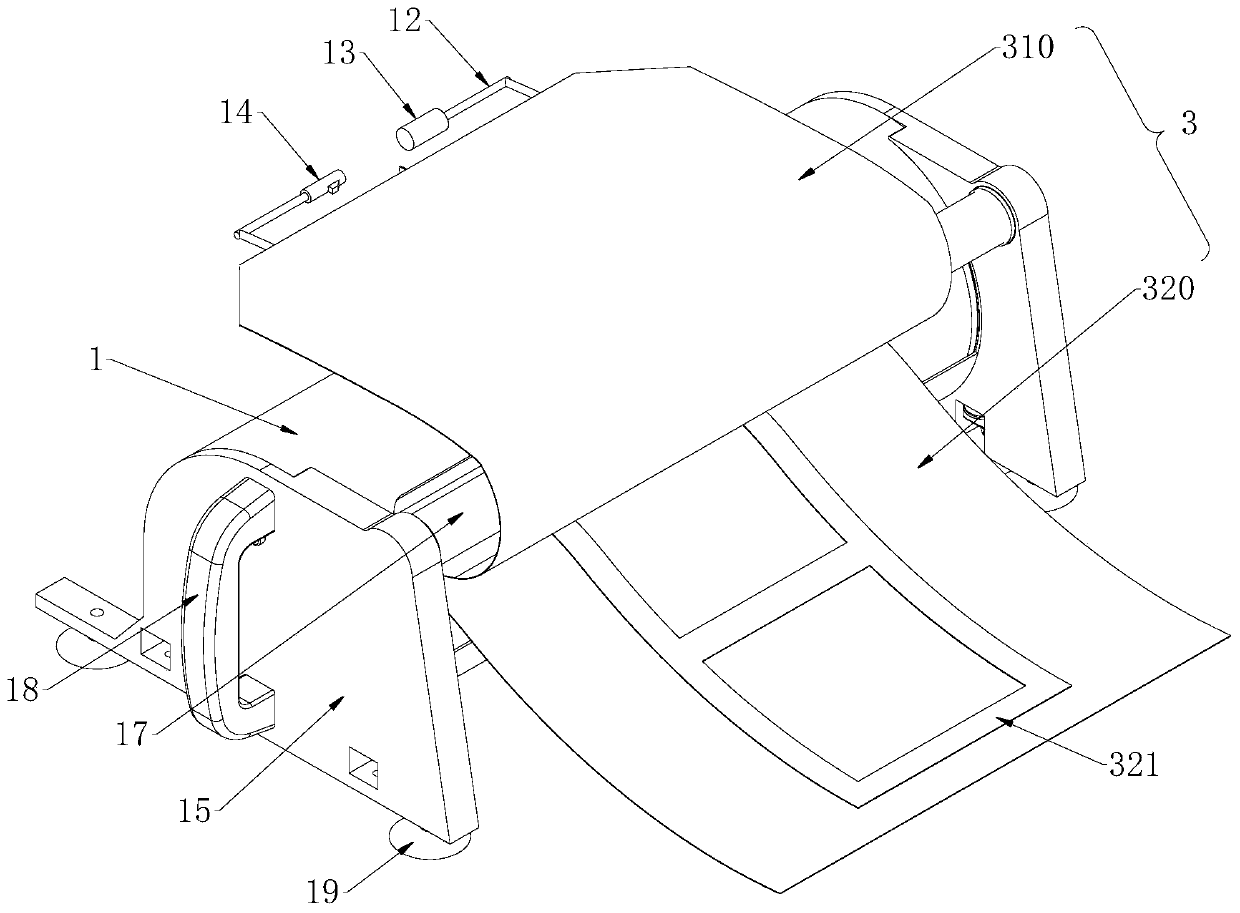

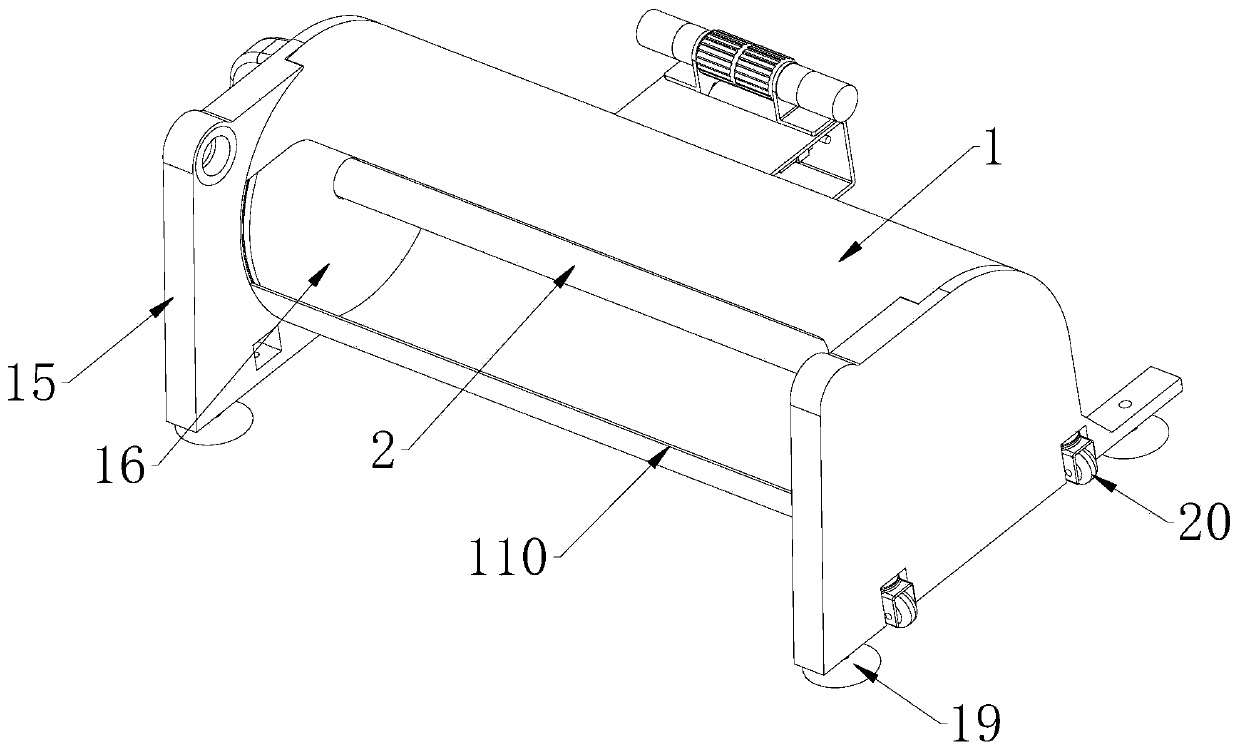

[0041] The fully automatic protective cover for vehicles of the present invention comprises a collection tube 1 located at the upper end of the vehicle body, a central shaft 2 is arranged to rotate inside the collection tube 1, a car body 3 is connected to the central shaft 2, and an opening is provided on the side wall of the collection tube 1 110; the cover body 3 is folded and wound on the central axis 2, the cover body 3 protrudes from the opening 110 to form the first cover 310 and the second cover 320 facing away from the back, and the first cover 310 is provided with The toothed belt 4 is provided with a gap between the toothed belt 4 and the first car cover 310, and the lower end of the first car cover 310 is connected with a connecting cloth 5, and the toothed belt 4 and the first car cover 310 are connected to each other by the connecting cloth 5, and the collected The outer wall of the barrel 1 is provided with a fixed frame 6, and the fixed frame 6 is provided with ...

Embodiment 2

[0044] This embodiment is further optimized on the basis of Embodiment 1 as follows: the profile of the connecting cloth 5 is T-shaped, the upper end of the connecting cloth 5 is connected to the first car cover 310, and the lower end of the connecting cloth 5 is connected to the first car cover. 310 are parallel to each other, two toothed belts 4 are arranged side by side, and the two toothed belts 4 are respectively located on the left and right sides of the connecting cloth 5; the left and right sides of the connecting cloth 5 are symmetrically provided with a driving unit 7, and the driving unit 7 includes a reduction motor 730, The motor bracket 720 and the gear 710, the reduction motor 730 and the fixed frame 6 are connected to each other through the motor bracket 720, the gear 710 is sleeved on the drive shaft of the reduction motor 730, the gear 710 is located in the gap, and the gear 710 and the toothed belt 4 mesh with each other .

[0045] After adopting the above t...

Embodiment 3

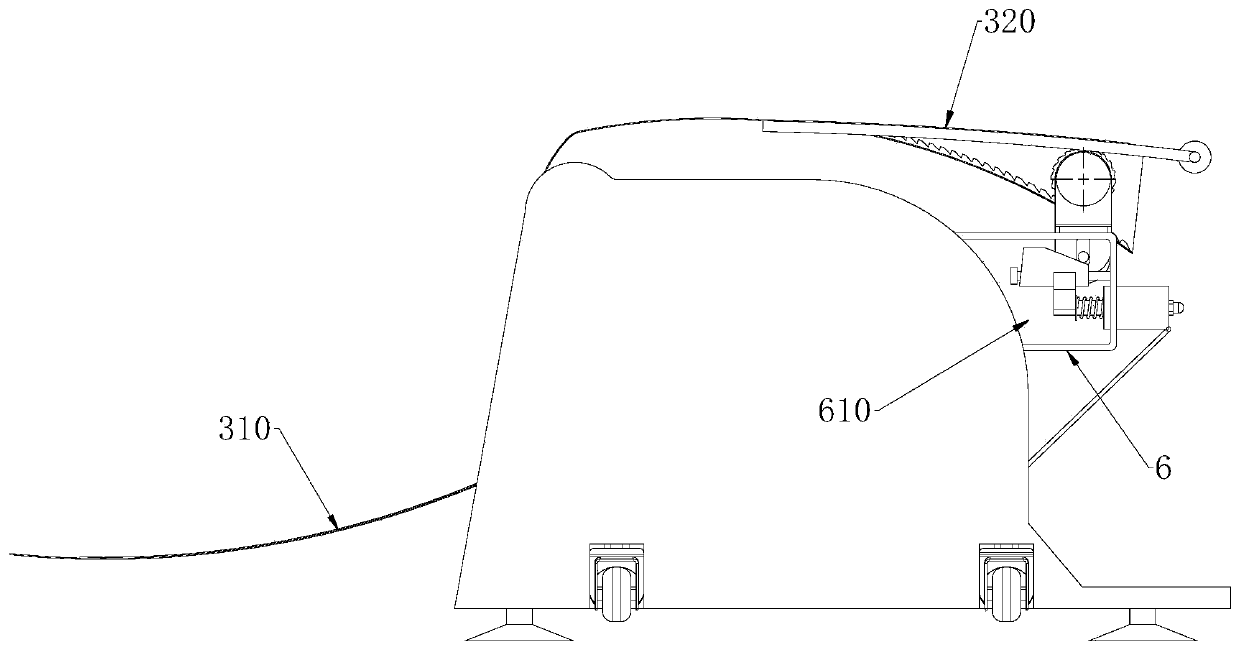

[0047] This embodiment is further optimized on the basis of Embodiment 1 as follows: a placement groove is formed between the fixed frame 6 and the outer wall of the collection tube 1, the toothed belt 4 is located above the placement groove, and the fixed frame 6 is provided with a groove for easy compression. The through hole for the lifting and moving of the wheel 8. The lower ends of the two motor brackets 720 extend into the placement groove after penetrating the fixed frame 6. The motor brackets 720 are provided with chute 721 along the vertical direction, and the two chute 721 are provided with There is a pressing wheel shaft 810, and the pressing wheel 8 is rotatably sleeved on the outside of the pressing wheel shaft 810, and the outer sides of the two chutes 721 are respectively provided with jacking units 9.

[0048] After adopting the above technical solution: the fixed frame 6 is formed by bending the upper and lower ends of a plate towards the direction close to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com