An air suspension bearing high-speed frequency conversion motor impeller production equipment

A frequency conversion motor, air suspension technology, applied in welding equipment, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of reducing production output, unable to continuously produce fan blades, unable to achieve automatic output, etc. Quality, improve quality and assembly efficiency, the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

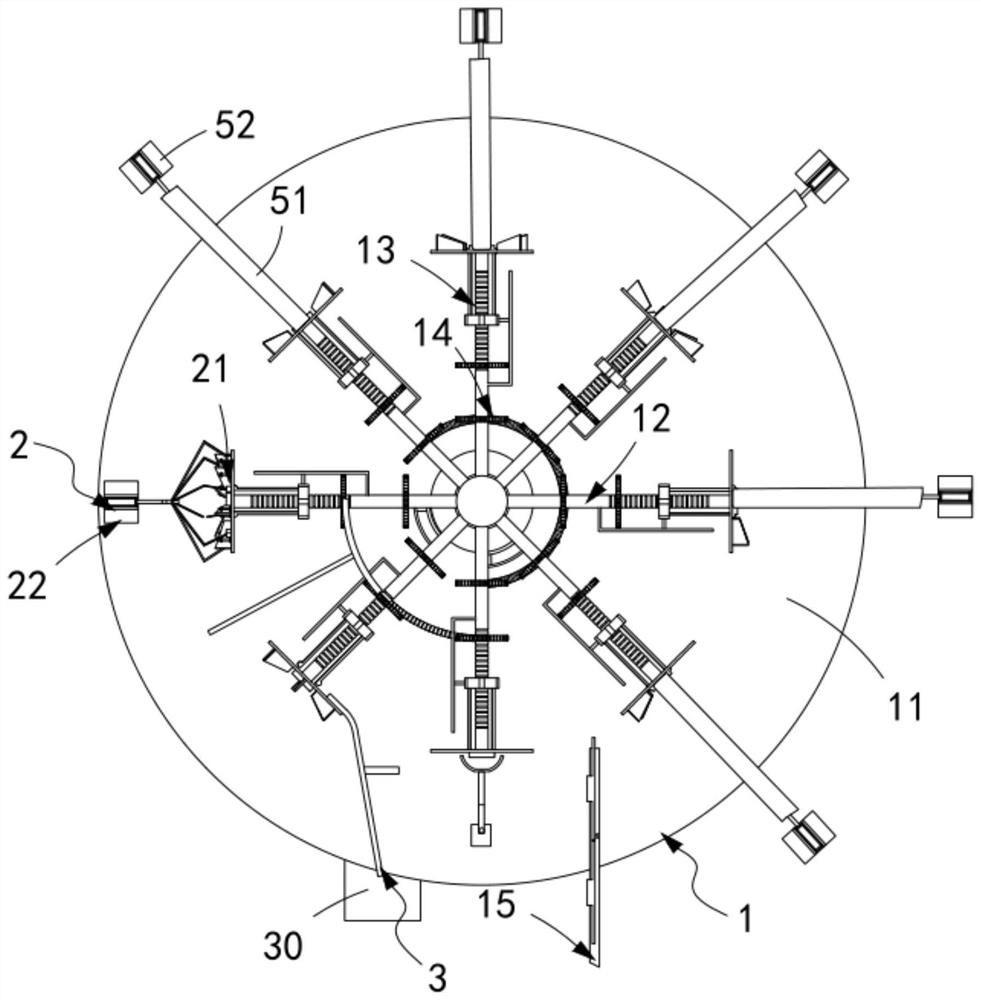

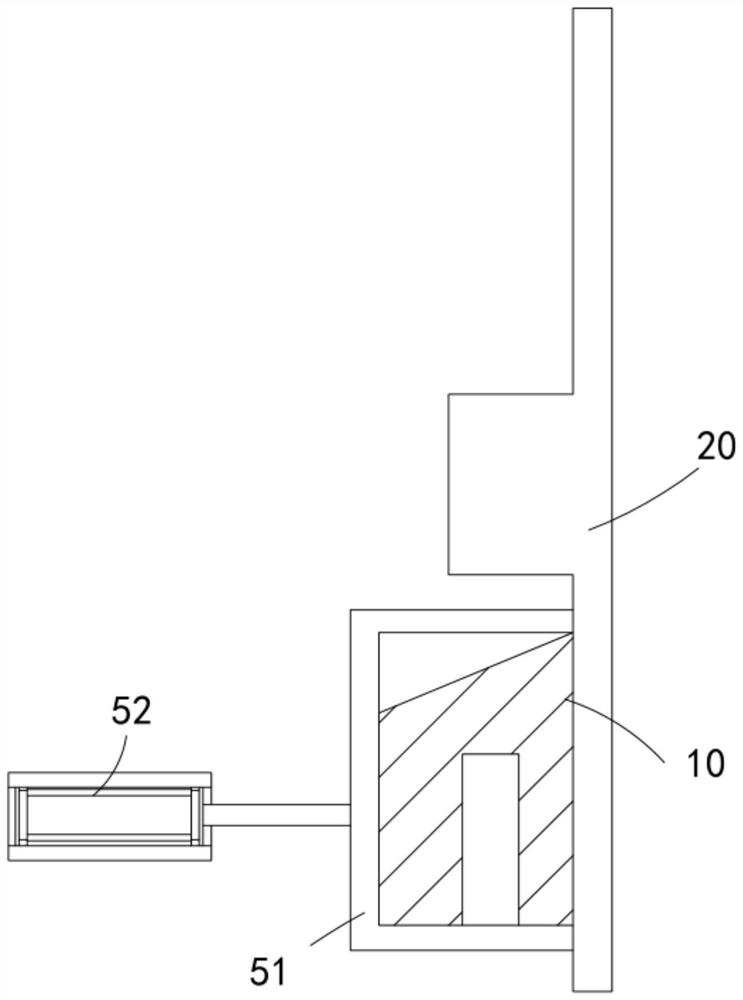

[0070] like figure 1 , Image 6 As shown, an air suspension bearing high-speed variable frequency motor impeller production equipment includes:

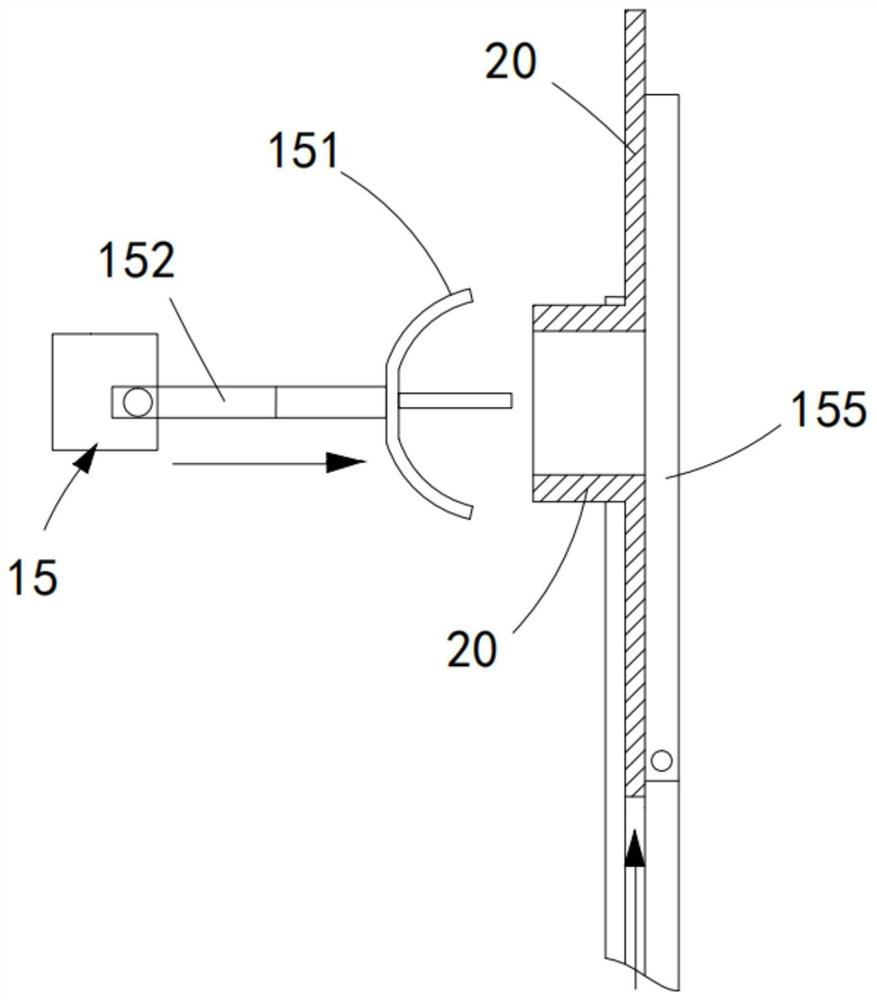

[0071] Assembling device 1, described assembling device 1 comprises support table 11, the loading assembly 12 that is arranged on described support table 11, the tightening assembly 13 that is arranged on described feeding assembly 12, is used for driving feeding assembly 12 to complete Several groups of blades 10 are uniformly uploaded to the switching assembly 14 and the seat assembly 15 is automatically installed on the blades 10 to the feeding assembly 12;

[0072] Grinding device 2, said grinding device 2 includes several sets of hair removal assemblies 21 that are evenly arranged and each group is slidably arranged between two adjacent blades 10 after welding, and is used to drive several groups of hair removal assemblies 21 to move synchronously The drive assembly 22; and

[0073] An output device 3, the output device 3 is ...

Embodiment 2

[0112] like Figure 17 , Figure 18 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0113] further, such as Figure 17 , Figure 18 As shown, the hair removal assembly 21 includes:

[0114] A connection block 211, the connection block 211 is slidably arranged on the support table 11 and located at the center between any two blades 10; and

[0115] The control piece 212, the control piece 212 is arranged in pairs on both sides of the connection block 211 and is respectively polished corresponding to the welded part of the blade 10, which includes a spring b213 fixedly connected with the connection block 211, and the spring b213 The other end of b213 is fixedly connected to the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com