Drilling device and automatic plate feeding and discharging drilling system

A technology of drilling equipment and drilling mechanism, which is applied in the direction of drilling/drilling equipment, boring/drilling, metal processing equipment, etc., which can solve the problems of large safety hazards and low work efficiency, and achieve the goal of improving safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

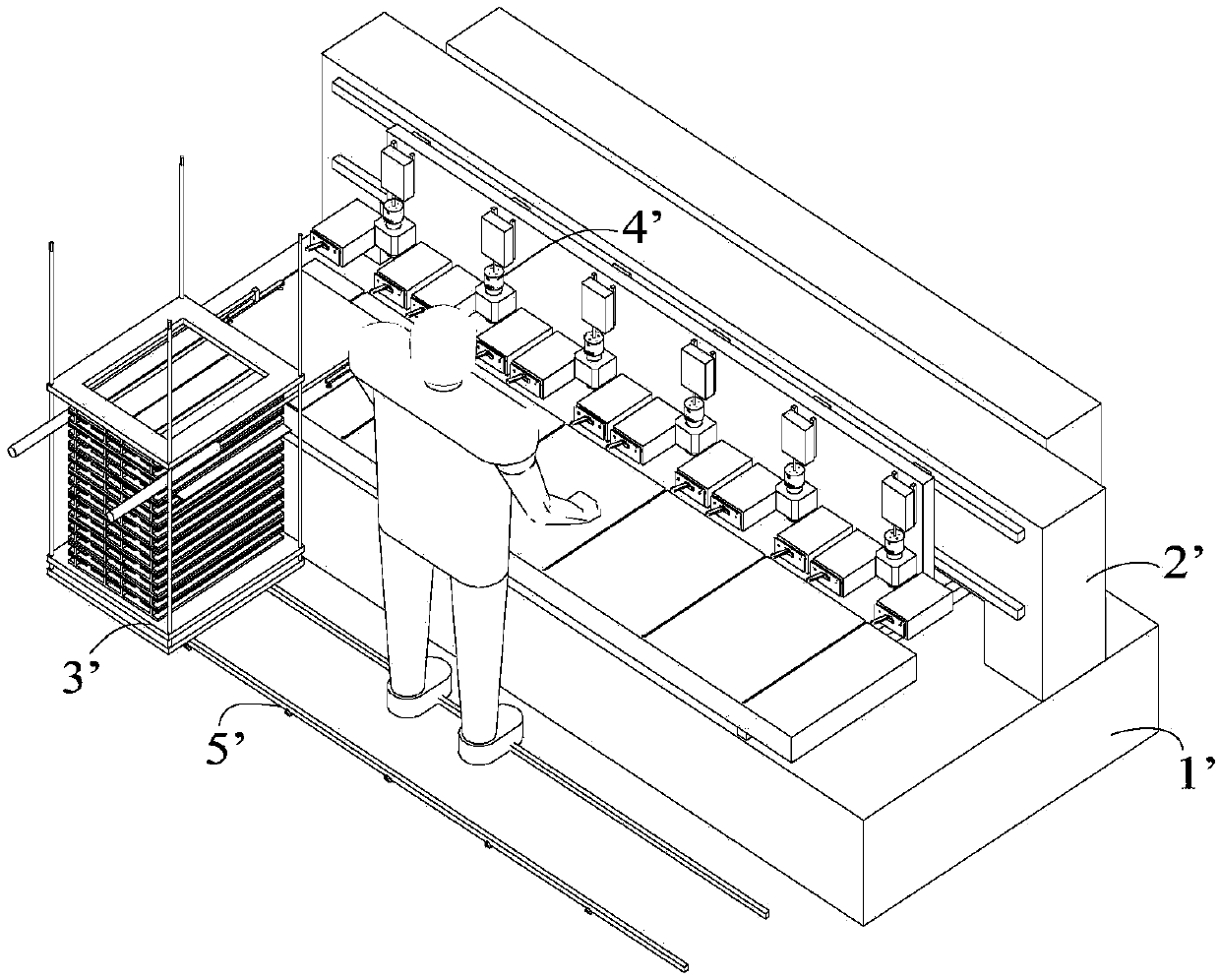

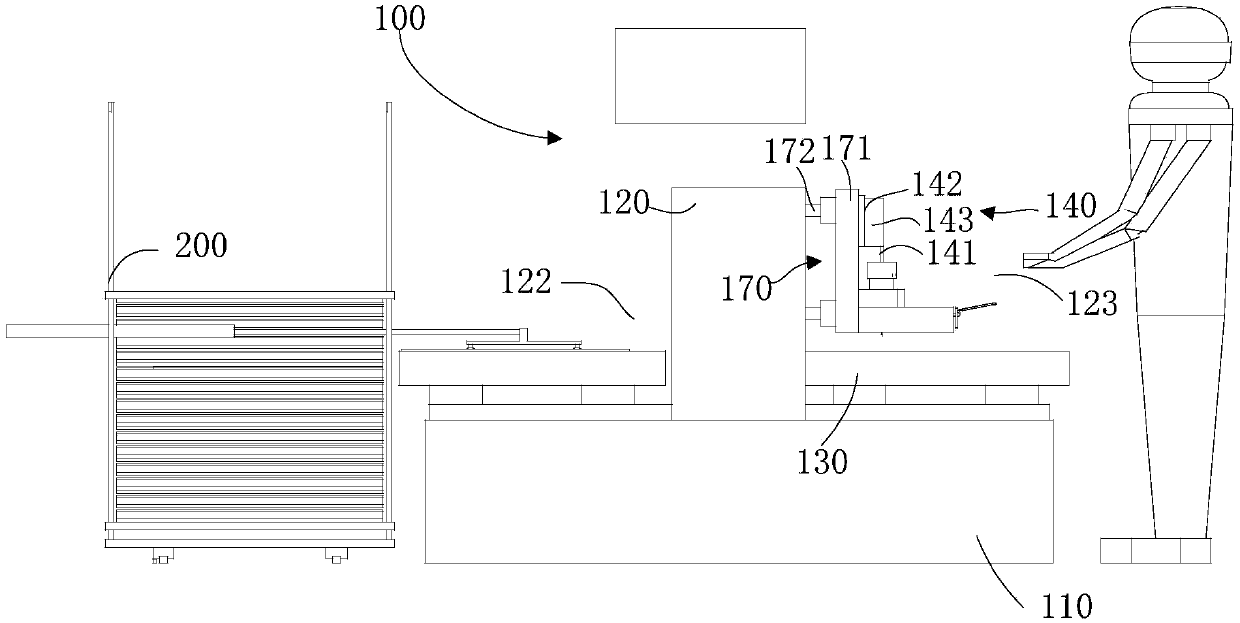

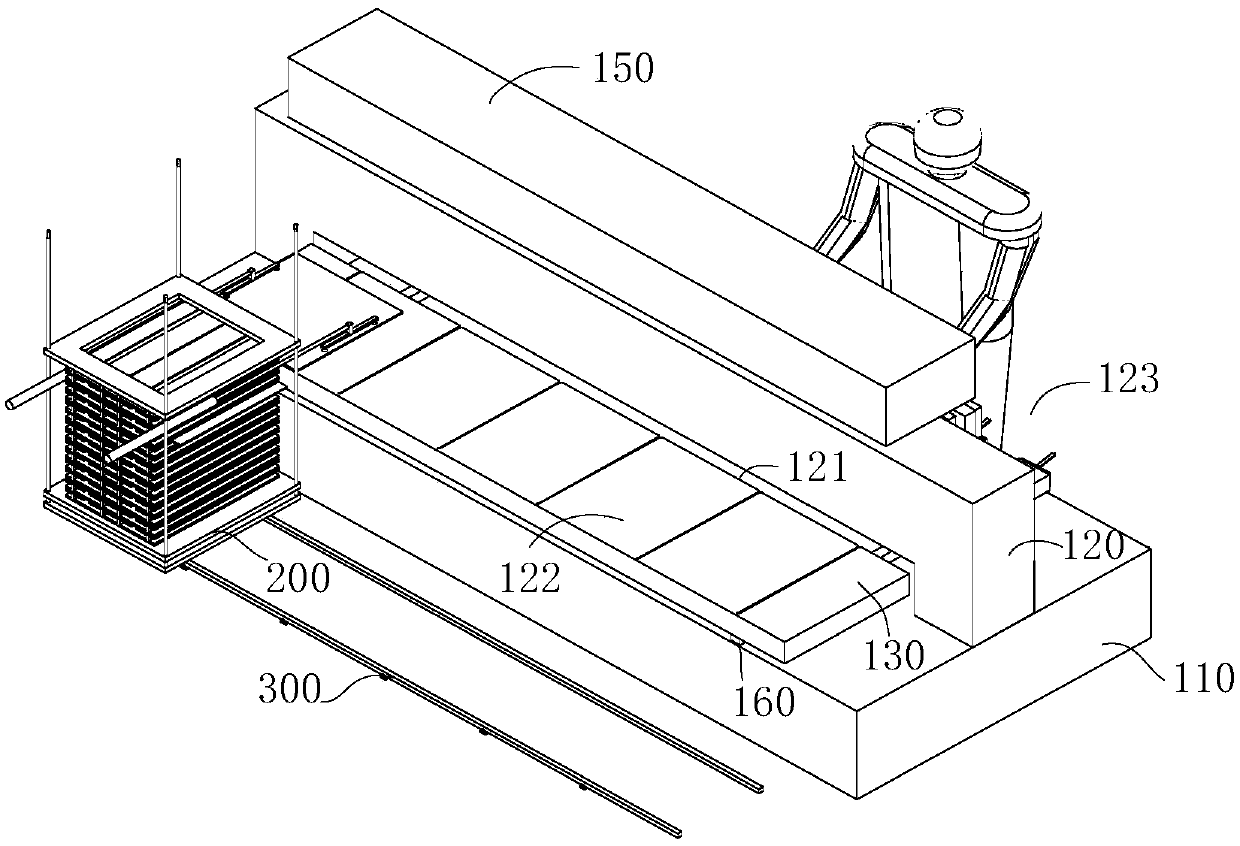

[0046] This embodiment provides a kind of drilling equipment, please refer to Figure 1 to Figure 4 , figure 1 It is a structural schematic diagram of the automatic upper and lower plate drilling system in the prior art; figure 2 The right view of the automatic upper and lower plate drilling system provided by the embodiment of the present invention; image 3 A schematic structural diagram of the first station in the automatic upper and lower plate drilling system provided by the embodiment of the present invention; Figure 4 It is a schematic structural diagram of the second station in the automatic upper and lower plate drilling system provided by the embodiment of the present invention.

[0047] Including: bed 110, crossbeam 120, workbench 130 and drilling mechanism 140; crossbeam 120 is located on the upper part of bed 110 and has channel 121 between bed 110, the two sides of crossbeam 120 form the first station 122 and the second Station 123, the first station 122 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com