Three-level control system and method for SVG device and computer storage medium

A three-level control and phase control technology, applied in circuit devices, flexible AC transmission systems, output power conversion devices, etc., can solve problems such as large control tasks and incompetent architecture, and achieve low control costs and low control delays , the effect of good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

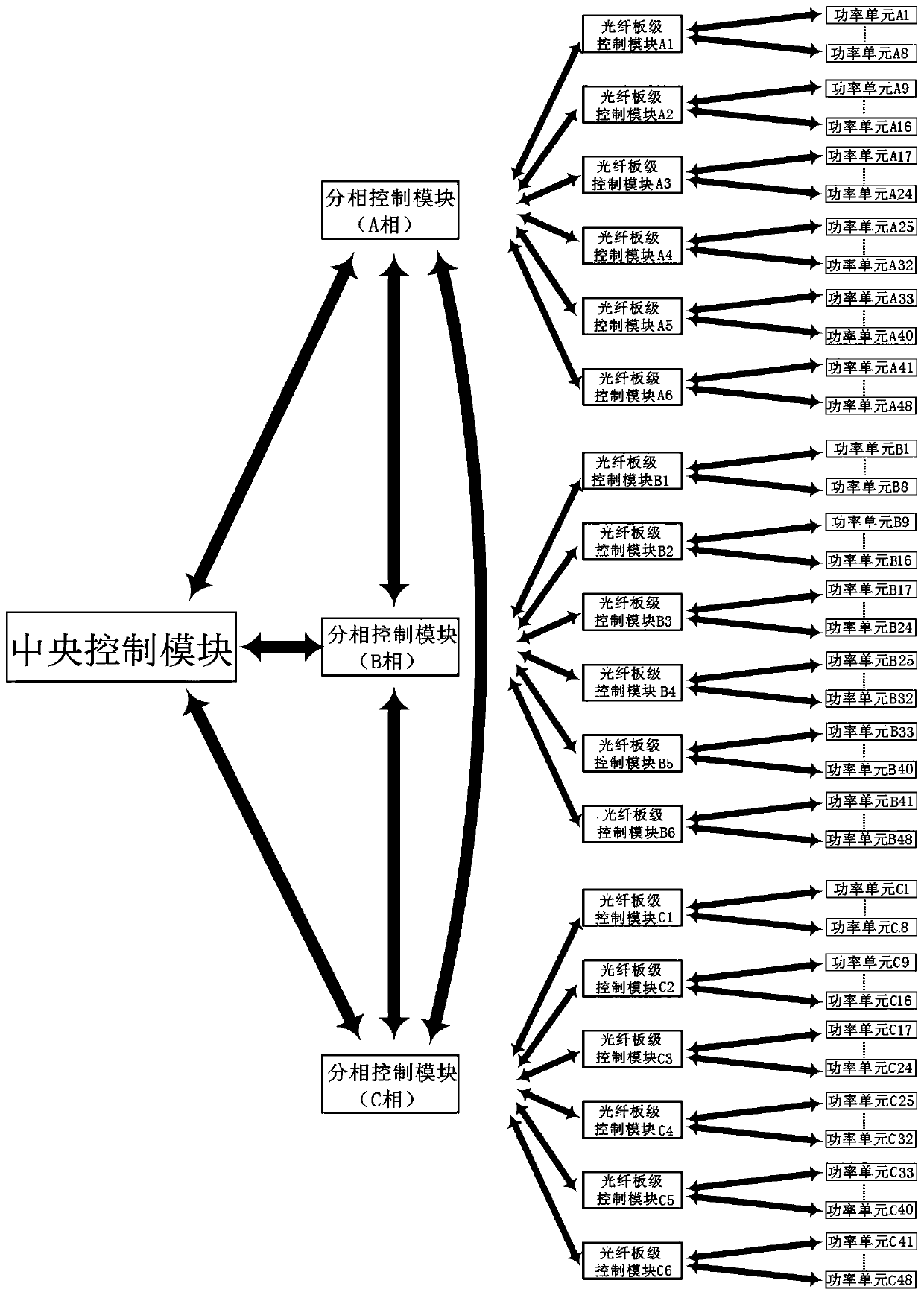

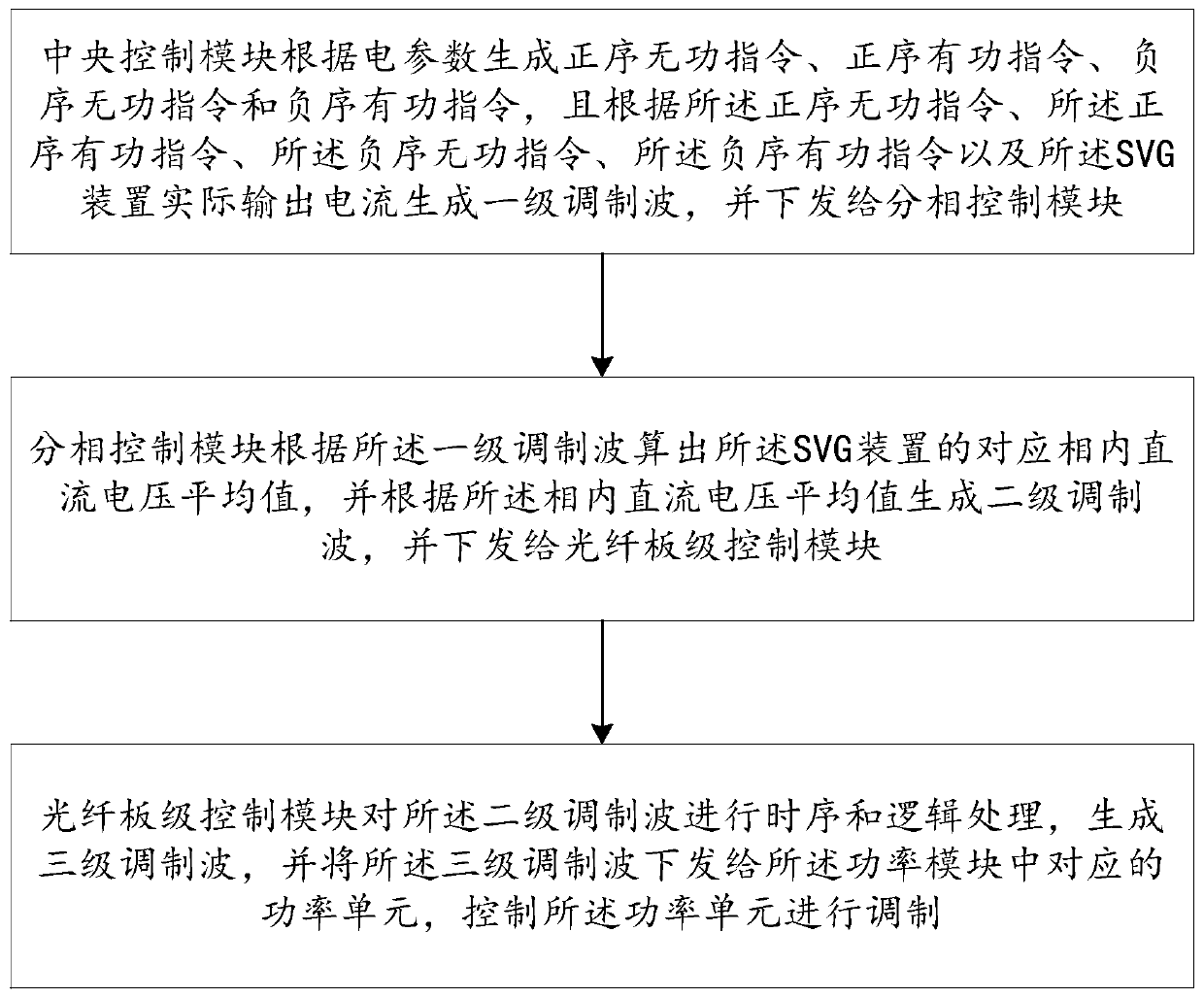

[0041] Such as figure 1 As shown, a three-level control system of an SVG device, the SVG device includes a power module composed of multiple power units cascaded; the three-level control system includes a central control module, a phase-splitting control module and an optical fiber board-level control module; the central control module, the phase-splitting control module, the fiber board-level control module and the power module are cascaded in sequence.

[0042] Specifically, there are three phase-splitting control modules, which are A-phase control module, B-phase control module, and C-phase control module, and the optical fiber board-level control module includes multiple A-phase optical fiber board-level control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com