Seamless splicing type LED circuit board

A technology of LED circuit boards and seamless splicing, which is applied in the directions of circuits, connections, and components of connecting devices, and can solve problems such as damage to circuit boards at sockets and plug connections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

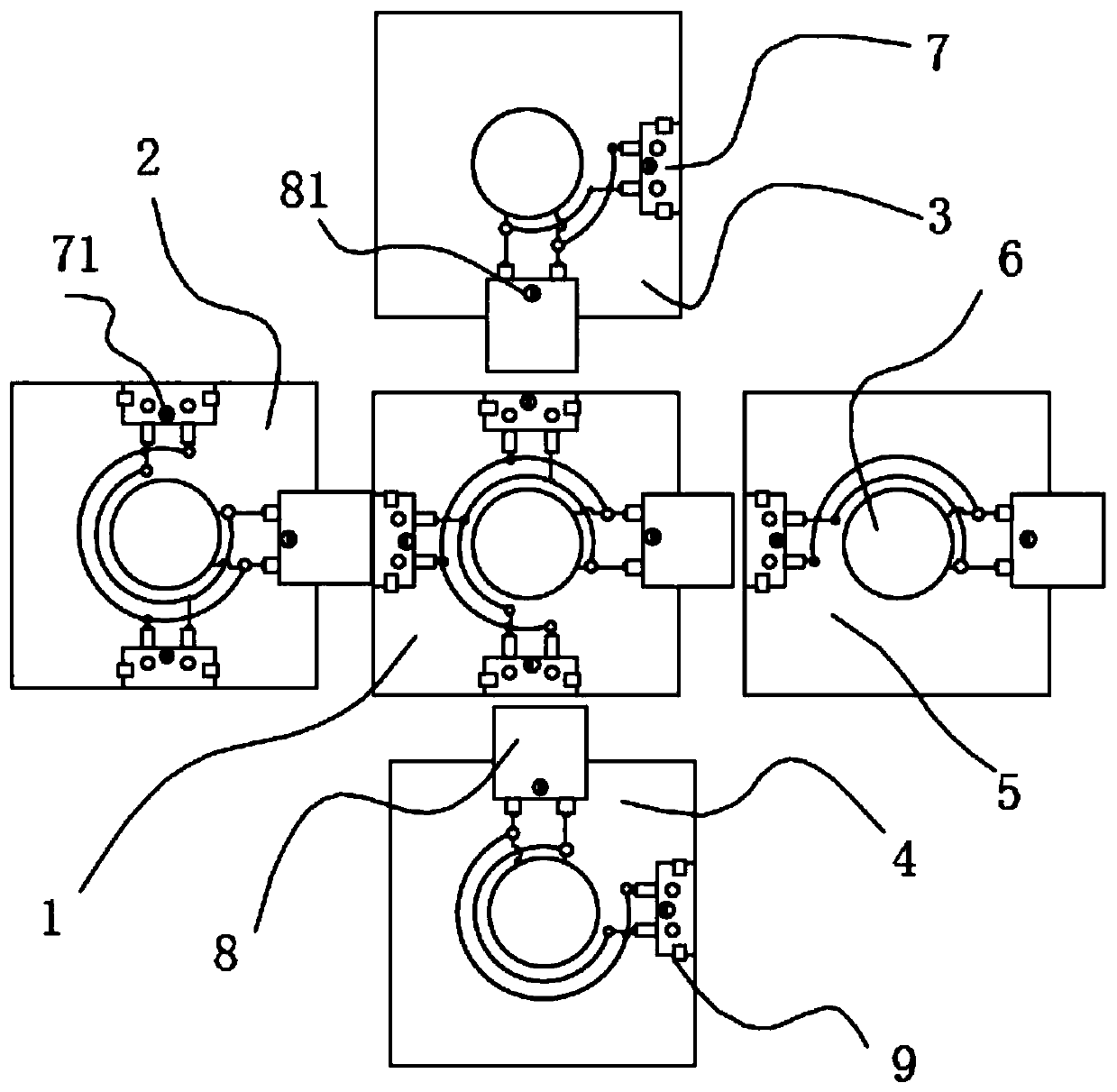

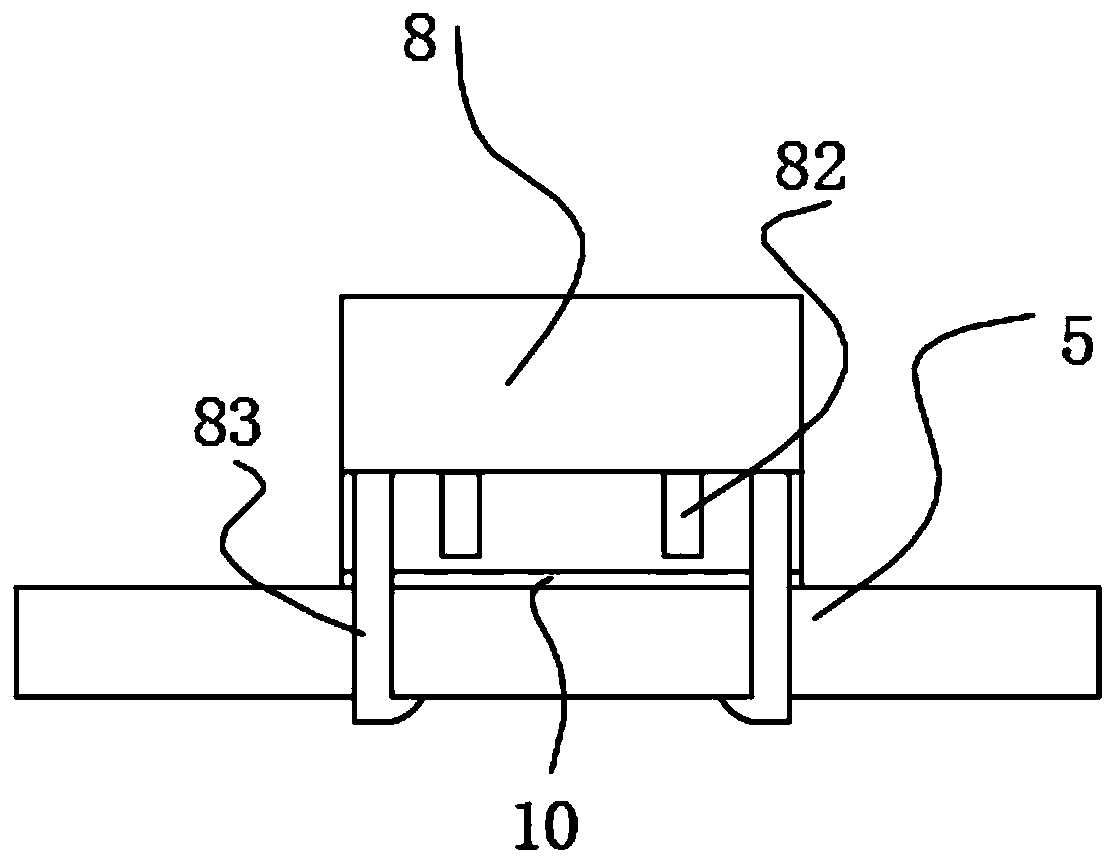

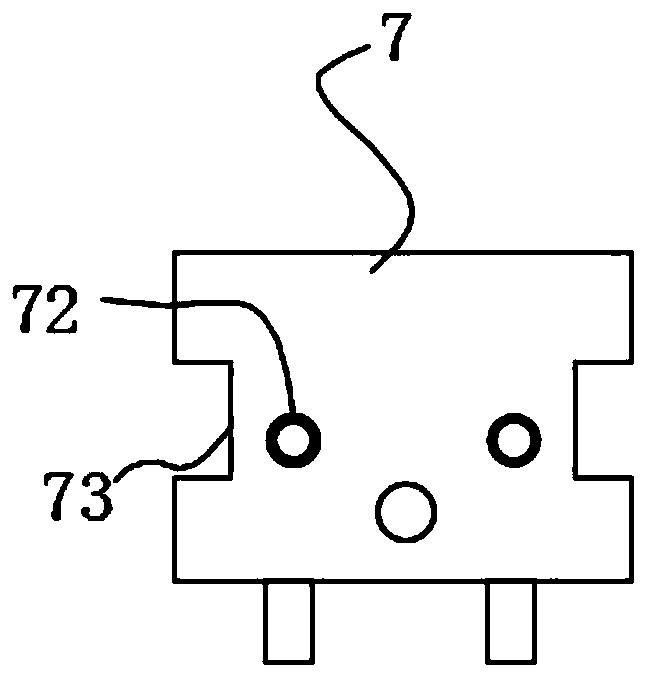

[0020] see figure 1 , the present invention provides a technical solution: a seamless splicing LED circuit board, including a four-way circuit board 1, a three-way circuit board 2, a left-corner circuit board 3, a right-corner circuit board 4 and a straight-through circuit board 5, four LED lights 6 are arranged on the surfaces of the through circuit board 1, the three-way circuit board 2, the left corner circuit board 3, the right corner circuit board 4 and the straight-through circuit board 5, the four-way circuit board 1, the three-way circuit board 2, The left corner circuit board 3, the right corner circuit board 4 and the straight-through circuit board 5 are spot welded and connected with the socket 7 and the plug 8, the four-way circuit board 1, the three-way circuit board 2, the left-corner circuit board 3, and the right turn Between the corner circuit board 4 and the straight-through circuit board 5, the installation of the corresponding shape can be completed by spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com