Preparation method of cobalt oxide-modified carbon-doped tin-manganese composite oxide nanofibers

A composite oxide and nanofiber technology, applied in the field of material chemistry, can solve the problems of insufficient cycle times and unsatisfactory charge-discharge curves, reducing volume expansion effect, improving electrochemical performance, improving electrical conductivity and cycle performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

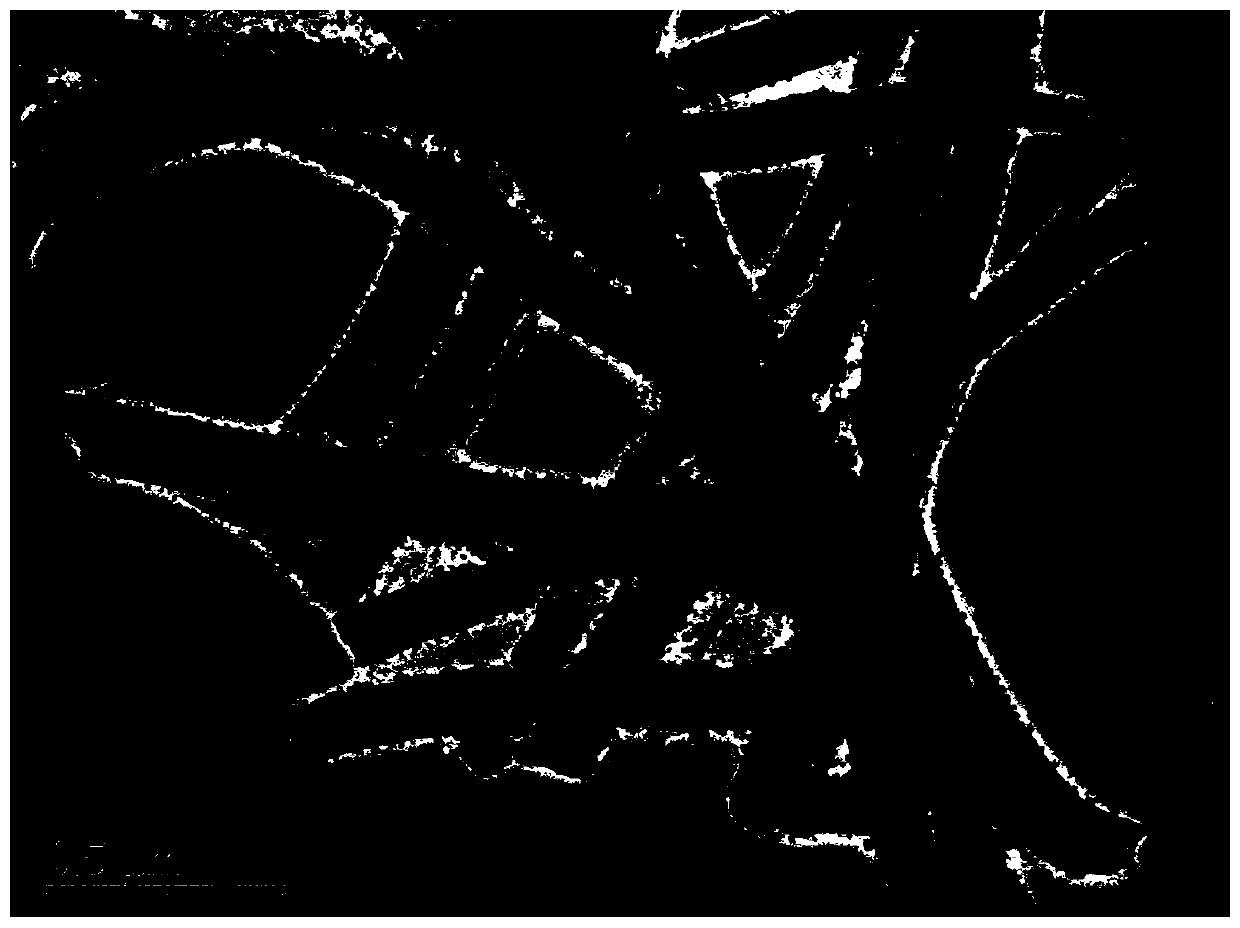

[0029] Weigh 1.0mmol (0.245g) of manganese acetate tetrahydrate (Mn(CH 3 COO) 2 4H 2 O), 1.0mmol (0.351g) dibutyltin oxalate (C 12 h 24 o 4 Sn) was dissolved in 10mL of N,N-dimethylformamide (DMF), then 2.0g of PAN (polyacrylonitrile) was added and stirred for 5h to obtain a light yellow mixture solution precursor; the above light yellow mixture The solution precursor was electrospun at a voltage of 17kV, a flow rate of 0.8mL / h, and an atmosphere with a relative humidity of 30%; the electrospun product obtained above was dried at 120°C;

[0030] Weigh 1.0mmol (0.096g) of 1,2-dimethylimidazole and dissolve it in 10mL of methanol to make solution A; weigh 1.0mmol (0.249g) of cobalt acetate tetrahydrate and dissolve it in 10mL of methanol to make a solution B;

[0031] The dried electrospun product obtained above was soaked in a solution containing Co 2+ Take it out after 30 minutes in methanol solution B containing ions, then take it out after soaking in methanol solution...

Embodiment 2

[0034] Weigh 1.0mmol (0.245g) of manganese acetate tetrahydrate (Mn(CH 3 COO) 2 4H 2 O), 1.0mmol (0.351g) dibutyltin oxalate (C 12 h 24 o 4 Sn) was dissolved in 10mL of N,N-dimethylformamide (DMF), then 2.0g of PAN (polyacrylonitrile) was added and stirred for 5h to obtain a light yellow mixture solution precursor; the above light yellow mixture The solution precursor was electrospun at a voltage of 19kV, a flow rate of 1.0mL / h, and an atmosphere with a relative humidity of 45%; the electrospun product obtained above was dried at 120°C;

[0035] Weigh 1.0mmol (0.096g) of 1,2-dimethylimidazole and dissolve it in 10mL of methanol to make solution A; weigh 2.0mmol (0.498g) of cobalt acetate tetrahydrate and dissolve it in 10mL of methanol to make a solution B;

[0036] The dried electrospun product obtained above was soaked in a solution containing Co 2+ Take it out after 30 minutes in methanol solution B containing ions, then take it out after soaking in methanol solution...

Embodiment 3

[0038] Weigh 1.0mmol (0.245g) of manganese acetate tetrahydrate (Mn(CH 3 COO) 2· 4H 2 O), 1.0mmol (0.351g) dibutyltin oxalate (C 12 h 24 o 4 Sn) was dissolved in 10mL of N,N-dimethylformamide (DMF), then 2.0g of PAN (polyacrylonitrile) was added and stirred for 5h to obtain a light yellow mixture solution precursor; the above light yellow mixture The solution precursor was electrospun at a voltage of 18kV, a flow rate of 0.9mL / h, and an atmosphere with a relative humidity of 40%; the electrospun product obtained above was dried at 120°C;

[0039] Weigh 1.0mmol (0.096g) of 1,2-dimethylimidazole and dissolve it in 10mL of methanol to make solution A; weigh 3.0mmol (0.747g) of cobalt acetate tetrahydrate and dissolve it in 10mL of methanol to make a solution B;

[0040] The dried electrospun product obtained above was soaked in a solution containing Co 2+ Take it out after 30 minutes in methanol solution B containing ions, then take it out after soaking in methanol solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com