Adjustable suspension formwork construction method without support at lower part

A construction method and an adjustable technology, applied in earth-moving drilling, mining equipment, mining equipment, etc., can solve the problem that the safety of the formwork support of the structural side wall and the construction quality of the structural side wall cannot be guaranteed, the main structure cannot meet the requirements of the node construction period, and the urban The problems such as the narrow space of the rail transit station have achieved the effect of avoiding the difficulty of construction organization, no potential safety hazards, and solving the tense construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

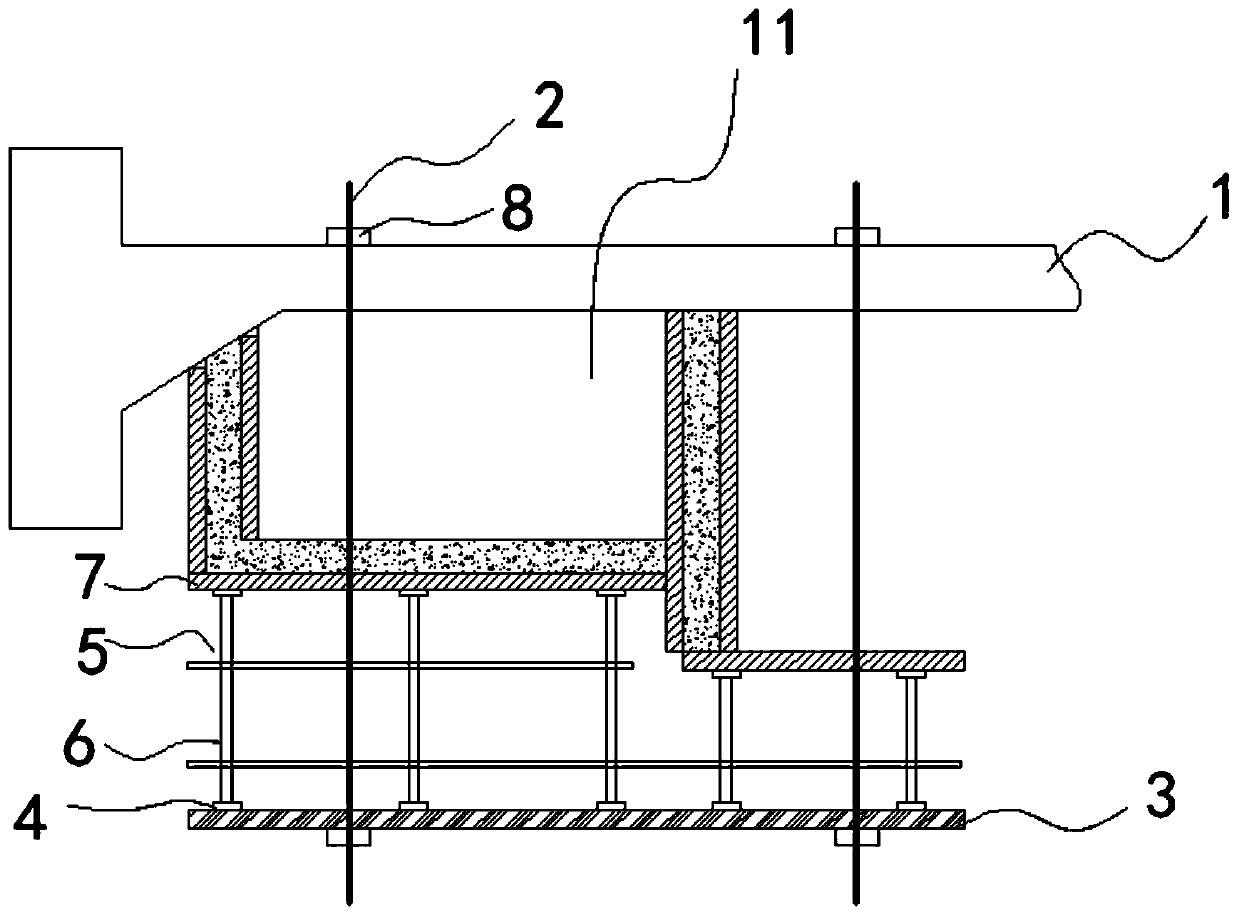

[0043] Such as Figure 1~3 As shown, a construction method of adjustable hanging formwork without support at the bottom is used for the construction of rail top air ducts in urban rail transit stations, including:

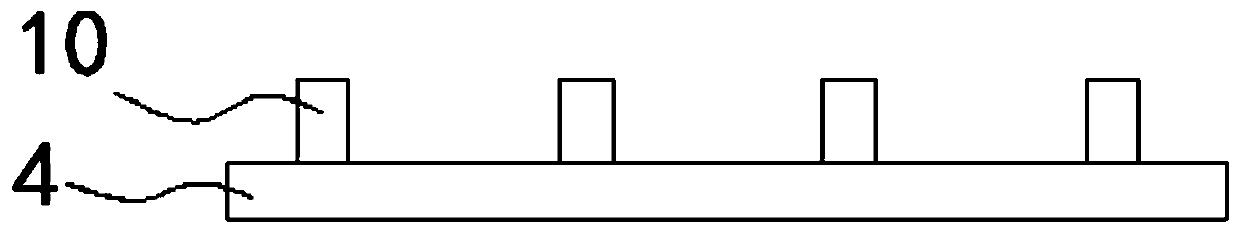

[0044] After a hole is opened on the middle plate 1 of the main structure of the station, a boom 2 is installed through the hole, a longitudinal beam 3 is hung on the boom 2, and a crossbeam 4 is built on the longitudinal beam 3 to form a support base;

[0045] Build the support 5 on the basis of the support, and then lay the main flute, the secondary flute and the formwork 7, thereby completing the hanging formwork construction.

[0046] Said suspenders 2 are provided with 2 lines horizontally and vertically at intervals of 2000 mm.

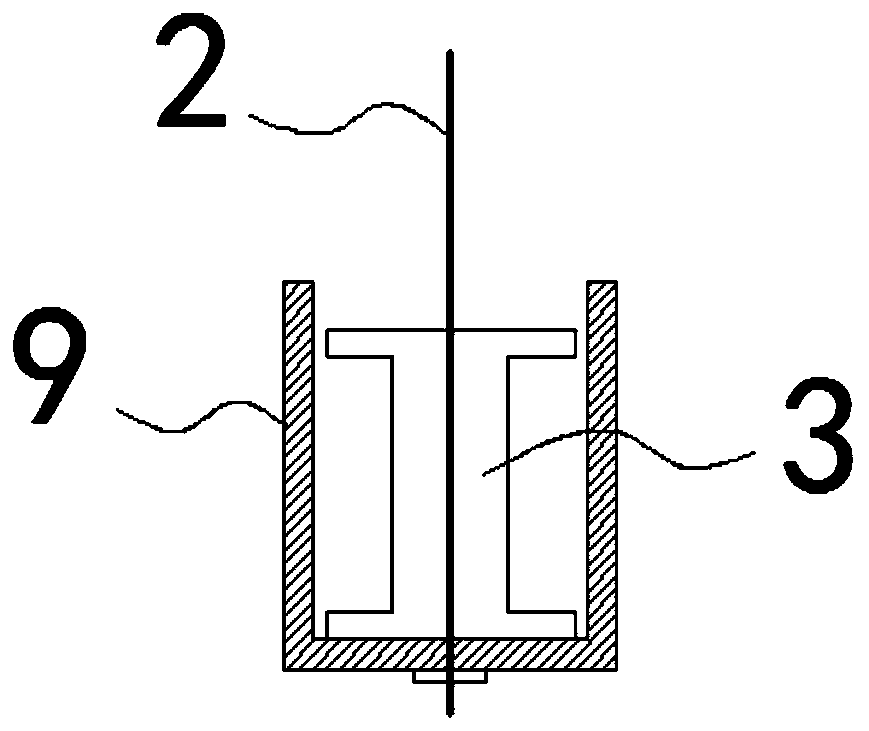

[0047] Specific as image 3 As shown, the lower end of the boom 2 is provided with a U-shaped bracket 9 , and the longitudinal beam 3 is lifted by the U-shaped bracket 9 .

[0048] The suspender 2 is a fine-rolled threaded steel ...

Embodiment 2

[0054] Such as Figure 1~4 As shown, a construction method of adjustable hanging formwork without support at the bottom is used for the construction of rail top air ducts in urban rail transit stations, including:

[0055] After a hole is opened on the middle plate 1 of the main structure of the station, a boom 2 is installed through the hole, a longitudinal beam 3 is hung on the boom 2, and a crossbeam 4 is built on the longitudinal beam 3 to form a support base;

[0056] Build the support 5 on the basis of the support, and then lay the main flute, the secondary flute and the formwork 7, thereby completing the hanging formwork construction.

[0057] Said suspenders 2 are provided with 2 lines horizontally and vertically at intervals of 2000 mm.

[0058] Specific as image 3 As shown, the lower end of the boom 2 is provided with a U-shaped bracket 9 , and the longitudinal beam 3 is lifted by the U-shaped bracket 9 .

[0059] The suspender 2 is a fine-rolled threaded steel ...

Embodiment 3

[0072] The technological process of the present invention: measuring and setting off → mechanical milling of the middle plate → installation of suspenders → installation of I-beams for longitudinal beams → installation of I-beams for crossbeams → erection of supports → laying of main corrugations, secondary corrugations and formwork.

[0073] Specifically: measure the center line of the Φ20 fine-rolled threaded suspender on the middle plate, arrange the row spacing at a vertical distance of 2m, mark the position of the hole, and then perform mechanical milling (the hole diameter is Φ32mm).

[0074] After the milling is completed, install the Φ20 fine-rolled thread suspenders and double-spelled 18# I-beam longitudinal beams, and install at least 2 U-shaped brackets under each double-spelled 18# I-steel longitudinal beams to connect with the suspenders ;Install the specification 100*100mm, t=10 steel pads on the top of the suspender (middle plate skin) and bottom (below the longi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com