Installation structure of prefabricated floor heating system

An installation structure and prefabricated technology, applied in building structures, local raised floors, floors, etc., can solve the problems of cumbersome processes, a lot of construction waste, material waste, etc., to achieve a simple construction process, save resources, and solve the problems of materials. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

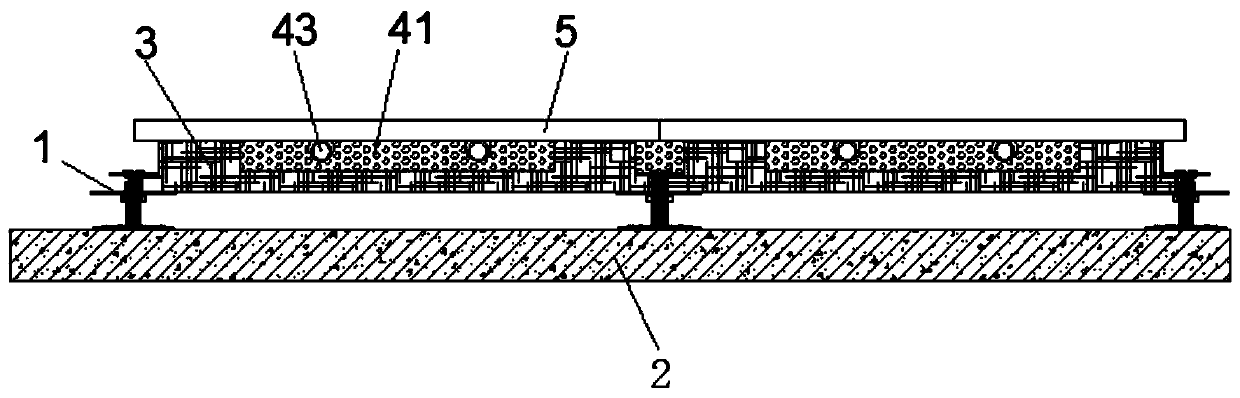

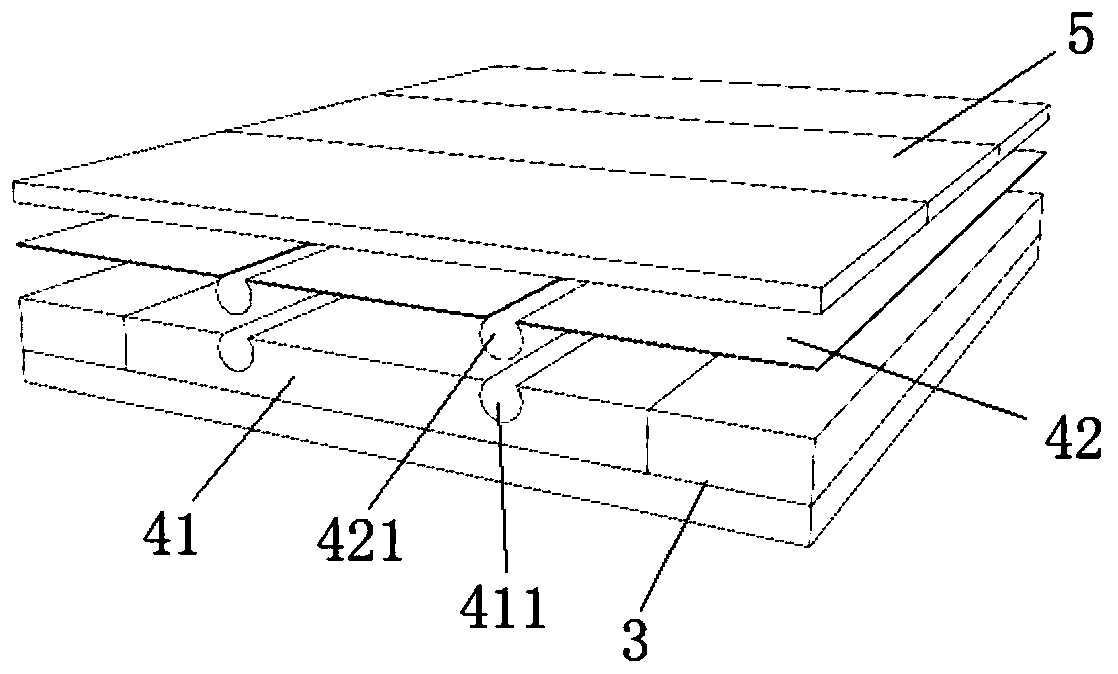

[0032] see Figure 1 to Figure 3 , the figure shows a prefabricated prefabricated floor heating installation structure provided by Embodiment 1 of the present invention, which includes a plurality of spliced floor heating installation units. The floor heating installation unit includes: leveling feet 1, which are set on the base floor 2; The bearing plate 3, its two ends are located on the leveling feet 1, and the bearing plate 3 is provided with an installation groove 31; the heat preservation component includes a heat preservation plate 41, an aluminum film reflection layer 42 and a floor heating pipe 43, and the heat preservation plate 41 is arranged in the installation groove 31, the aluminum film reflective layer 42 is arranged on the upper surface layer of the insulation board 41; Located on the inner surface of the pipe groove 411, the floor heating pipe 43 is arranged in the arc strip 421; the interface plate 5 is arranged on the heat preservation component.

[0033...

Embodiment 2

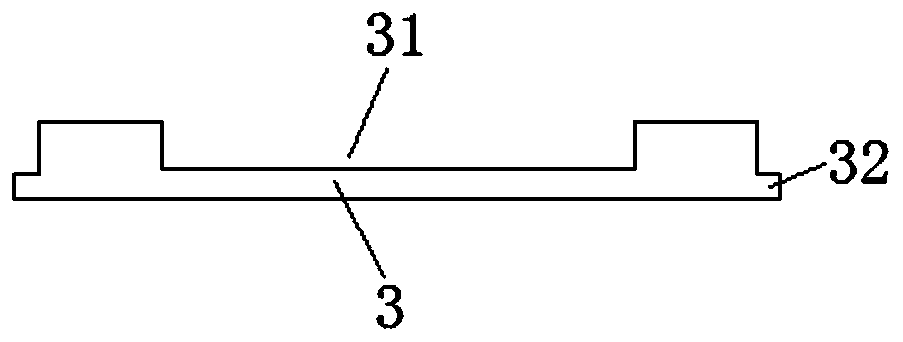

[0041] see Figure 1 to Figure 2 , the figure shows the installation structure of an assembled prefabricated floor heating provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: bearing plate 3 The material is GRC; the two sides of the bearing plate 3 are provided with connecting plates 32 for connecting the leveling feet 1; Through the setting of the above structure, the connection force between the bearing plate 3 and the leveling foot 1 is increased, which can improve the stability of the whole heat preservation assembly.

Embodiment 3

[0043] see image 3 , the figure shows the installation structure of an assembled prefabricated floor heating provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: thermal insulation board 41 The thickness is greater than the thickness of the aluminum foil reflective layer 42; the number of pipe grooves 411, arc strips 421 and floor heating pipes 43 are set in one-to-one correspondence; the inner diameter of pipe grooves 411 is greater than the outer diameter of arc strips 421, and the inner diameter of arc strips 421 greater than the outer diameter of the floor heating pipe 43 . Through the setting of the above structure, the sequential installation of the arc bar 421 and the floor heating pipe 43 can be ensured, and the damage of the floor heating pipe 43 caused by abrasion due to size can be avoided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com