Single railing body and novel railing assembly type stair railing and construction method thereof

A stair handrail and construction method technology, applied to railings, stepped structures, building structures, etc., can solve the problems of monotonous structure, uncoordinated installation, inconvenient operation, etc., achieve beautiful and durable appearance, various surface colors, and meet the needs of users The effect of the function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

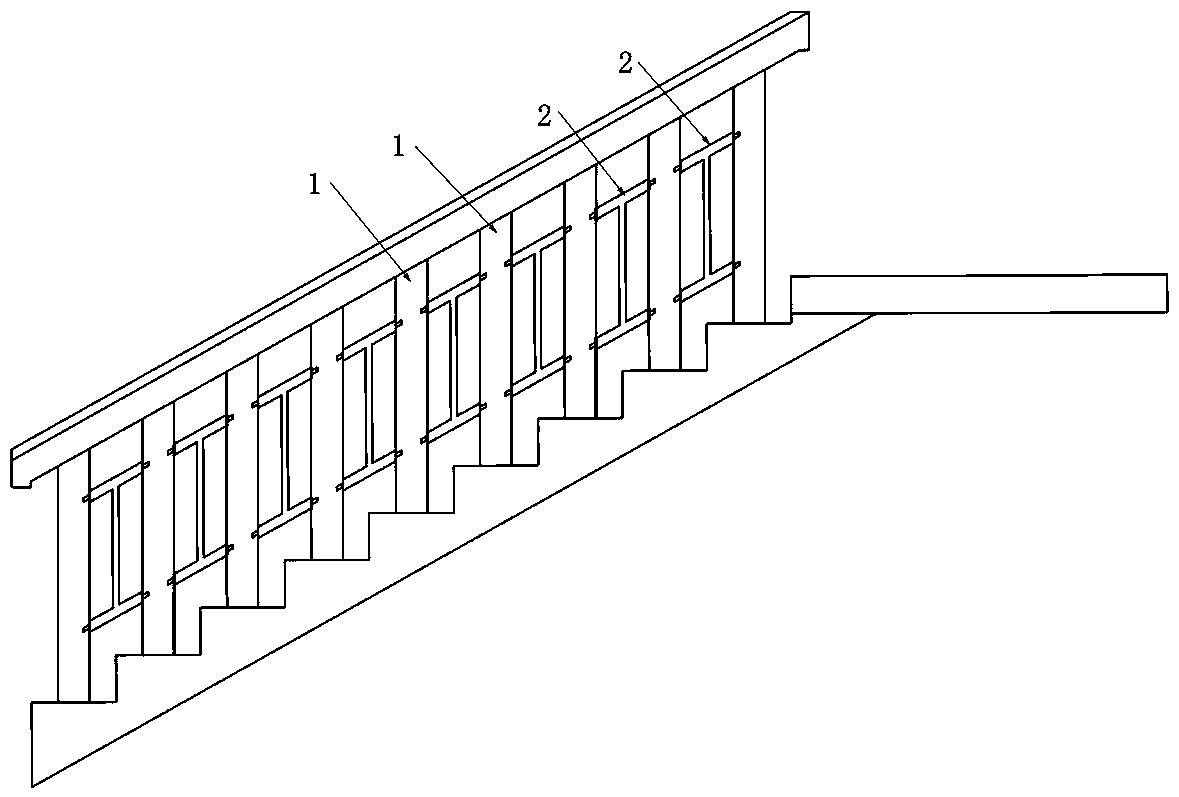

[0038] Such as Figure 1-7 As shown, the railing monomer, the railing monomer 1 includes an integrated column 1.1, the top of the integrated column 1.1 is integrally connected with an upper cross bar 1.2, and the bottom end of the integrated column 1.1 is pre-embedded with a U-shaped joint code 1.3 , one end of the upper cross bar 1.2 is the first connection end 1.4, and the other end is the second connection end 1.5, and the first connection end 1.4 of one upper cross bar 1.2 can be connected with the other end of the upper cross bar 1.2. Cooperate with the second connecting end 1.5.

[0039] In this embodiment, one of the first connecting end 1.4 and the second connecting end 1.5 is a groove, and the other is a protrusion; the second connecting end 1.5 is opposite to the first connecting end 1.4 And the height is staggered, the upper surface of the middle section of the first connecting end 1.4 has a groove-3, the end of the second connecting end 1.5 has a bump-4 matching w...

Embodiment 2

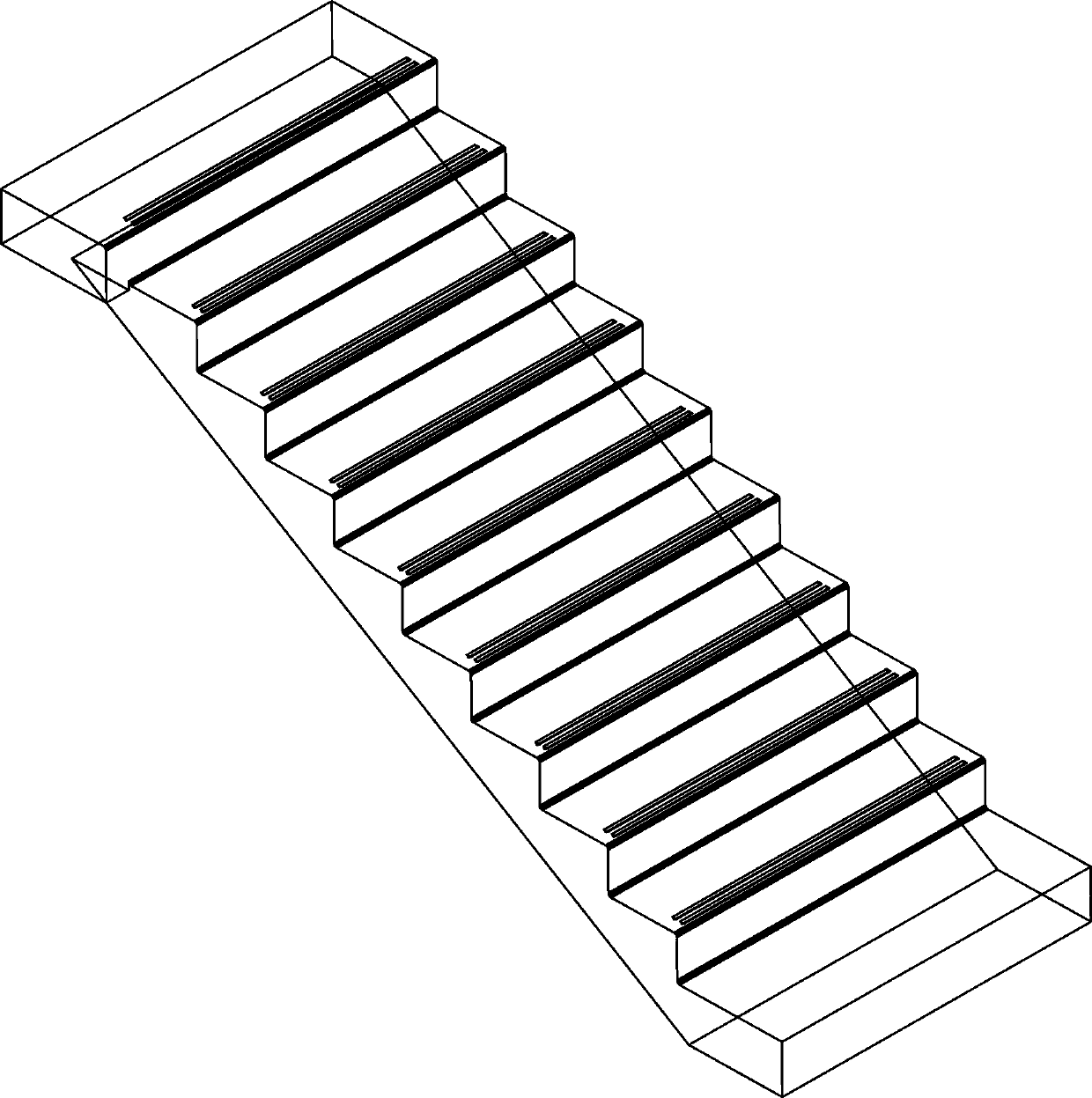

[0041] Such as Figure 1-7 As shown, the new railing assembly type stair handrail railing of the present invention includes the above-mentioned railing monomer 1, including a plurality of railing monomers 1, and the plurality of railing monomers 1 are connected in sequence, so that the upper crossbar 1.2 is on the same straight line A plug-in guardrail 2 is also provided between the adjacent integrated columns 1.1. The plug-in guardrail 2 is an I-shaped structure, and the two ends of the two beams of the plug-in guardrail 2 are respectively clamped on the corresponding integrated column 1.1.

Embodiment 3

[0043] The construction method of the novel handrail assembly type stair handrail of the present invention is characterized in that: comprising the following steps:

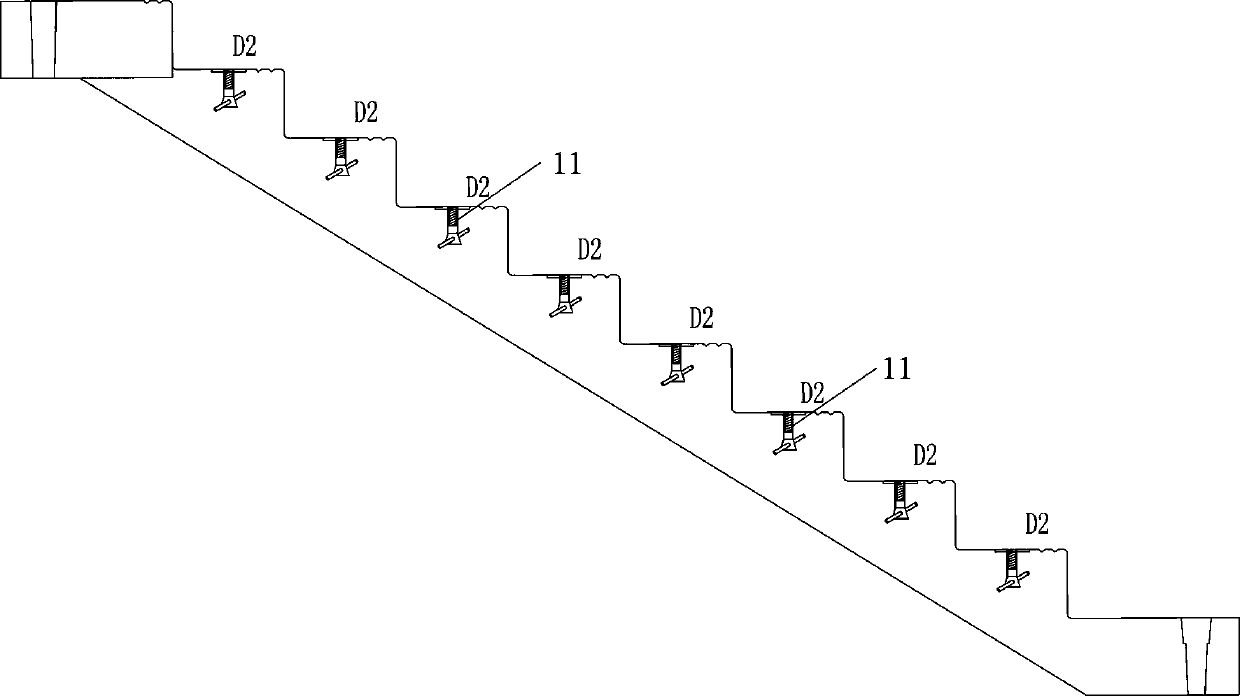

[0044] Step 1, install the prefabricated integrated column 1.1, the lowermost end of the integrated column 1.1 is prefabricated with a U-shaped connecting code 1.3, and the two ends of the U-shaped connecting code 1.3 are fixedly connected with the prefabricated integrated column 1.1 of the stairs through M8 screws;

[0045] Step 2, the bottom end of the U-shaped connecting code 1.3 is bolted to the stairs through the embedded parts 11 of the prefabricated stair section. The embedded parts 11 are M16×100mm nuts, and the nuts are completely penetrated into the The connection in the reserved hole of the stair section, the embedded part in the reserved hole is a steel plate of 80×80×6mm;

[0046] Step 3, install the plug-in guardrail 2, and perform mortise and tenon connection by inserting the reserved convex posts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com