Construction method of continuous composite beam bridge and continuous composite beam bridge

A construction method and steel girder technology, applied to bridges, bridge parts, bridge materials, etc., can solve the problems of increasing the amount of wet work on site, affecting the bearing capacity of bridges, and poor concrete prestress, so as to reduce the amount of wet work on site and improve The effect of prestressing efficiency and reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

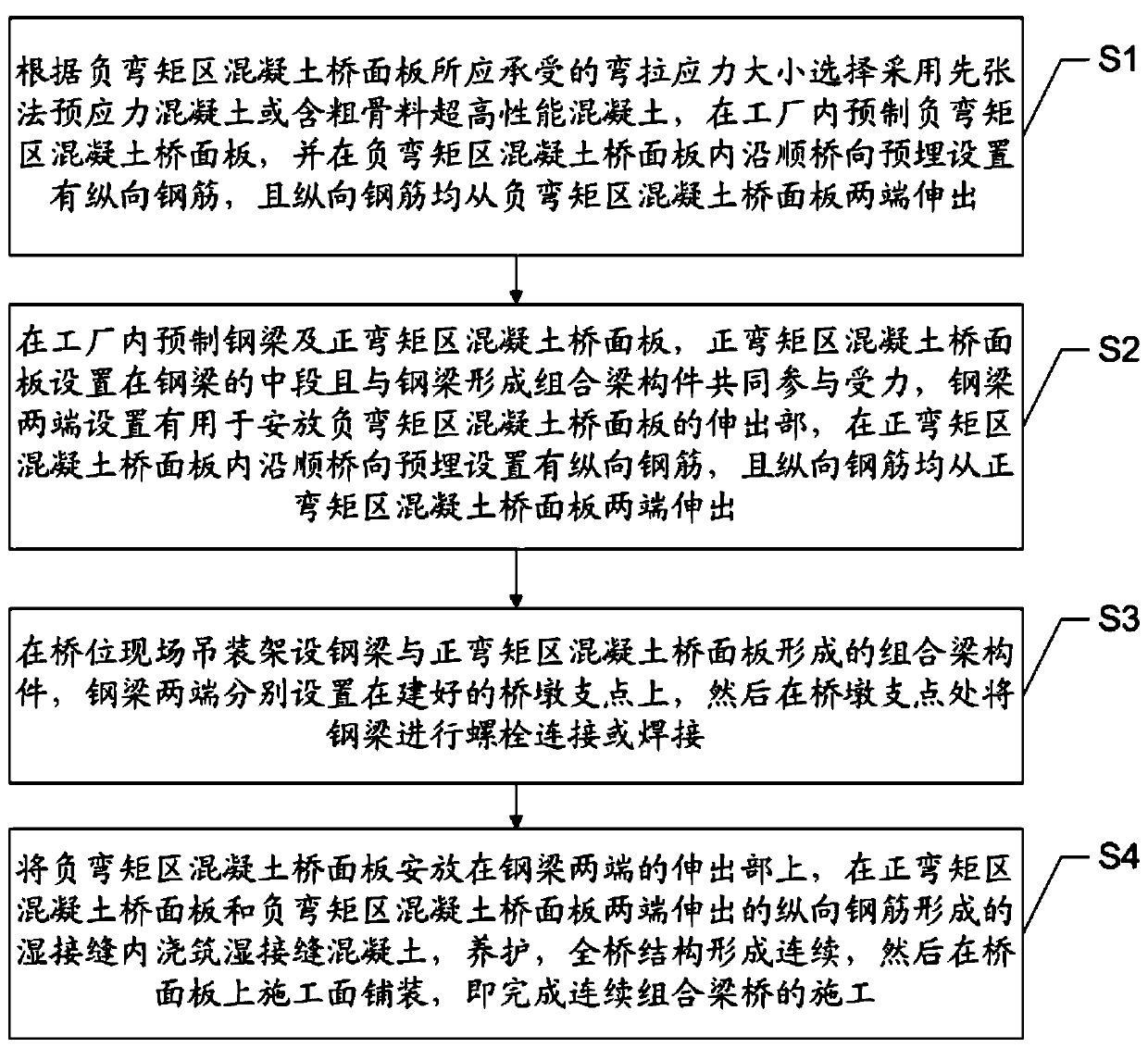

[0036] Such as figure 1 as shown, figure 1 It is a flow chart of a construction method for a continuous composite girder bridge provided in an embodiment of the present invention, comprising the following steps:

[0037] S1. Pre-tensioned prestressed concrete or ultra-high-performance concrete containing coarse aggregate is selected according to the bending and tensile stress of the concrete bridge deck in the negative bending moment area, and the concrete bridge deck in the negative bending moment area is prefabricated in the factory. The concrete bridge deck in the negative moment zone is pre-embedded with longitudinal steel bars along the bridge direction, and the longitudinal steel bars protrude from both ends of the concrete bridge deck in the negative bending moment zone.

[0038]Specifically, when the bending and tensile stress of the concrete bridge deck in the negative bending moment area is greater than or equal to 8MPa, the concrete bridge deck in the negative bend...

Embodiment 2

[0058] like Figure 2-5 As shown, the embodiment of the present invention provides a continuous composite girder bridge, including: pier 9, a steel girder 1 arranged on the pier 9, a concrete bridge deck 2 in a positive moment zone and a negative moment zone set on the steel girder 1 Concrete bridge deck 3; steel girder 1, concrete bridge deck 2 in the positive bending moment area, and concrete bridge deck 3 in the negative bending moment area are all prefabricated. Specifically, the negative bending moment area specifically refers to spanning from the fulcrum to both sides of the bridge for 0.1- 0.5 times the bridge span range.

[0059] Among them, the concrete bridge deck 2 in the positive moment zone is arranged in the middle section of the steel beam 1 and forms a prefabricated composite beam member together with the steel beam 1 to participate in the force bearing. The concrete bridge deck 2 and the steel girder 1 in the positive bending moment area are jointly stressed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com