Clean production method for neomycin sulfate fermentation

A neomycin sulfate and clean production technology, which is applied in fermentation and other fields, can solve the problems of high energy consumption and heavy pollution, and achieve the effects of stable ammonia nitrogen index, large steam consumption, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for clean production of neomycin sulfate fermentation, the method comprises the following steps:

[0036] Step 1: Inoculate sandy soil spores to the slant, and prepare the slant spore suspension after cultivating at 28±1°C for 4 to 8 days;

[0037] Step 2: Put the slant spore suspension into a seed tank equipped with a seed medium, and cultivate for 35-40 hours to obtain a seed liquid;

[0038] Step 3: Connect the seed liquid into a fermenter equipped with a fermentation base medium, and ferment for 150 to 180 hours to obtain a fermentation liquid. During the fermentation process, add feed medium and ammonium sulfate to allow the accumulation of neomycin to reach Fermentation is terminated after the end point of the fermentation is required to obtain a fermented liquid,

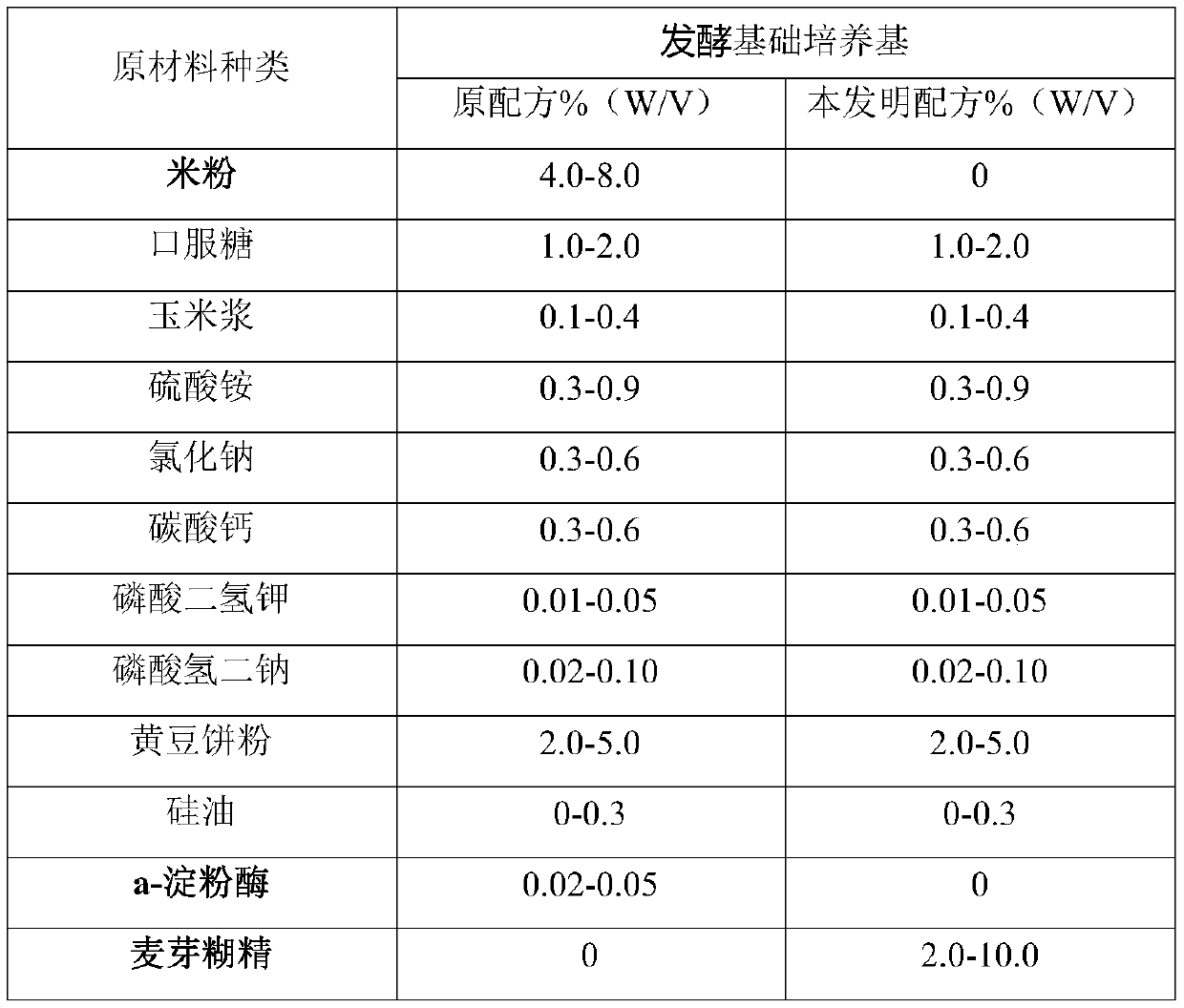

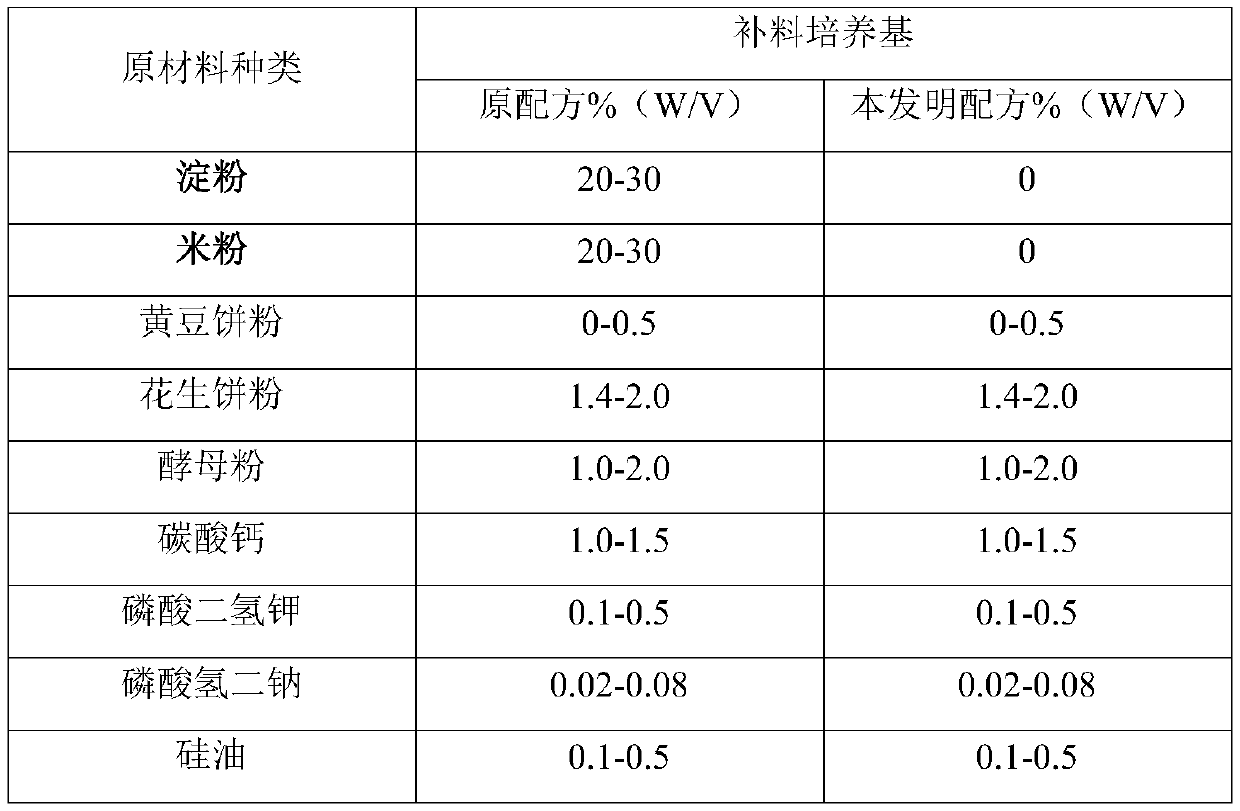

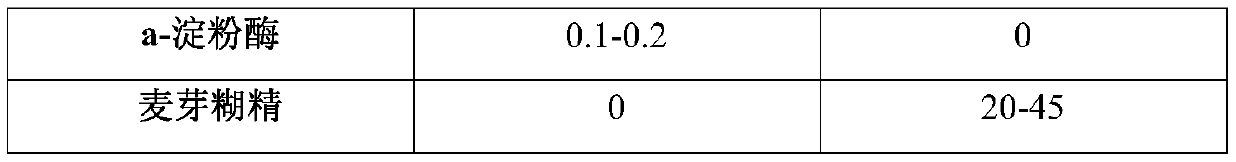

[0039] Wherein, the fermentation basal medium includes 2% (W / V) maltodextrin, and the fermentation basal medium does not contain rice flour and α-amylase;

[0040] The feed medium includes 2...

Embodiment 2

[0054] A method for clean production of neomycin sulfate fermentation, the method comprises the following steps:

[0055] Step 1: Inoculate sandy soil spores to the slant, and prepare the slant spore suspension after cultivating at 28±1°C for 4 to 8 days;

[0056] Step 2: Put the slant spore suspension into a seed tank equipped with a seed medium, and cultivate for 35-40 hours to obtain a seed liquid;

[0057] Step 3: Connect the seed liquid into a fermenter equipped with a fermentation base medium, and ferment for 150 to 180 hours to obtain a fermentation liquid. During the fermentation process, add feed medium and ammonium sulfate to allow the accumulation of neomycin to reach Fermentation is terminated after the end point of the fermentation is required to obtain a fermented liquid,

[0058] Wherein, the fermentation basal medium includes 5% (W / V) maltodextrin, and the fermentation basal medium does not contain rice flour and α-amylase;

[0059] The feed medium includes 3...

Embodiment 3

[0073] A method for clean production of neomycin sulfate fermentation, the method comprises the following steps:

[0074] Step 1: Inoculate sandy soil spores to the slant, and prepare the slant spore suspension after cultivating at 28±1°C for 4 to 8 days;

[0075] Step 2: Put the slant spore suspension into a seed tank equipped with a seed medium, and cultivate for 35-40 hours to obtain a seed liquid;

[0076] Step 3: Connect the seed liquid into a fermenter equipped with a fermentation base medium, and ferment for 150 to 180 hours to obtain a fermentation liquid. During the fermentation process, add feed medium and ammonium sulfate to allow the accumulation of neomycin to reach Fermentation is terminated after the end point of the fermentation is required to obtain a fermented liquid,

[0077] Wherein, the fermentation basal medium includes 10% (W / V) maltodextrin, and the fermentation basal medium does not contain rice flour and α-amylase;

[0078] The feed medium includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com