Water-based drilling fluid and preparation method thereof

A water-based drilling fluid and water-based fluid technology, applied in the field of drilling fluid, can solve the problems of low passing rate and achieve the effects of strong antibacterial ability, excellent rheological properties and low activity of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] In addition, the preparation method of the above-mentioned water-based drilling fluid includes the following steps:

[0077] 1) maintaining the pH of the system at 8-10 after mixing the alkalinity regulator with the water-based liquid;

[0078] 2) Add other components of the water-based drilling fluid and mix to obtain the water-based drilling fluid.

[0079] In addition, the above-mentioned water-based drilling fluid system or the water-based drilling fluid system prepared by the above-mentioned method is used for operations in sea areas with strict environmental protection requirements.

[0080] In the embodiment of the present invention, the anhydrous sodium carbonate and sodium hydroxide are purchased from Sinopharm Group, analytically pure, 500g;

[0081] In the embodiment of the present invention, the environmental-friendly fluid loss control agent is carboxymethyl modified starch, purchased from Beijing Zhongke Risheng Chemical Auxiliary Company, model: PF-BIOFL...

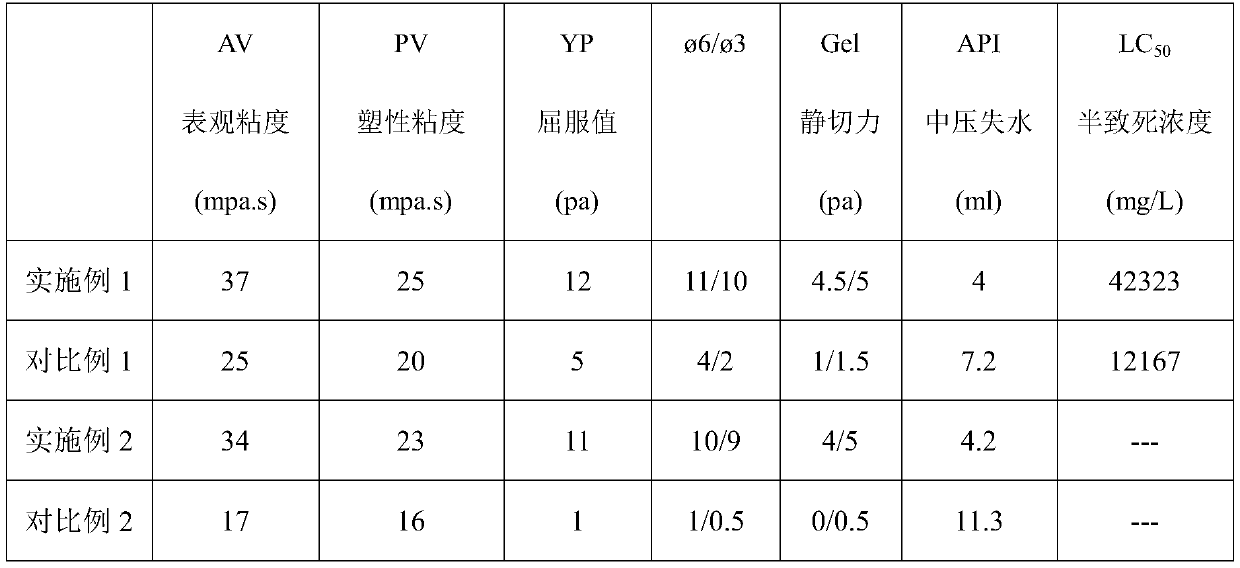

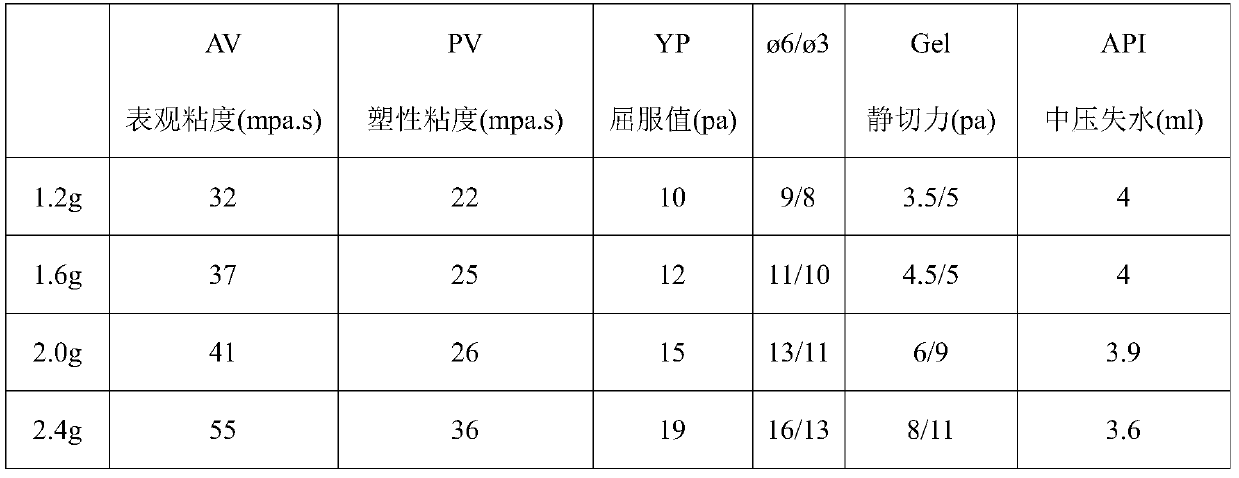

Embodiment 1

[0094] Preparation of water-based drilling fluid: Measure 400ml of seawater with a measuring cylinder and place it in the slurry cup. Add 0.8g of anhydrous sodium carbonate, 0.8g of sodium hydroxide, and 8g of environmentally friendly fluid loss reducer in turn while stirring at a speed of 11,000r / min. , 1.6g environment-friendly low molecular weight coating agent, 1.2g environment-friendly cutting agent, 12g environment-friendly inhibitor, 8g environment-friendly blocking agent, 48g sodium chloride, barite weighted to 1.2g / cm 3 .

Embodiment 2

[0099] The method of Example 1 was used to prepare water-based deepwater water-based drilling fluid, except that the amount of sodium chloride was increased to 80g.

[0100] Preparation of water-based drilling fluid: Measure 400ml of seawater with a measuring cylinder and place it in the slurry cup. Add 0.8g of anhydrous sodium carbonate, 0.8g of sodium hydroxide, and 8g of environmentally friendly fluid loss reducer while stirring at a speed of 11,000r / min. agent, 1.6g environment-friendly low molecular weight coating agent, 1.2g environment-friendly cutting agent, 12g environment-friendly inhibitor, 8g environment-friendly blocking agent, 80g sodium chloride, barite weighted to 1.2g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com