Rosin quaternary ammonium salt antibacterial coating compound based on modified non-woven fabric and preparation method and application thereof

A quaternary ammonium compound and antibacterial coating technology, which is applied in the field of new fungicides, can solve problems such as increasing the pain of patients with weight gain, increasing medical costs, and slowing down wound healing, achieving high-efficiency sterilization performance, green raw material sources, mechanical properties and The effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

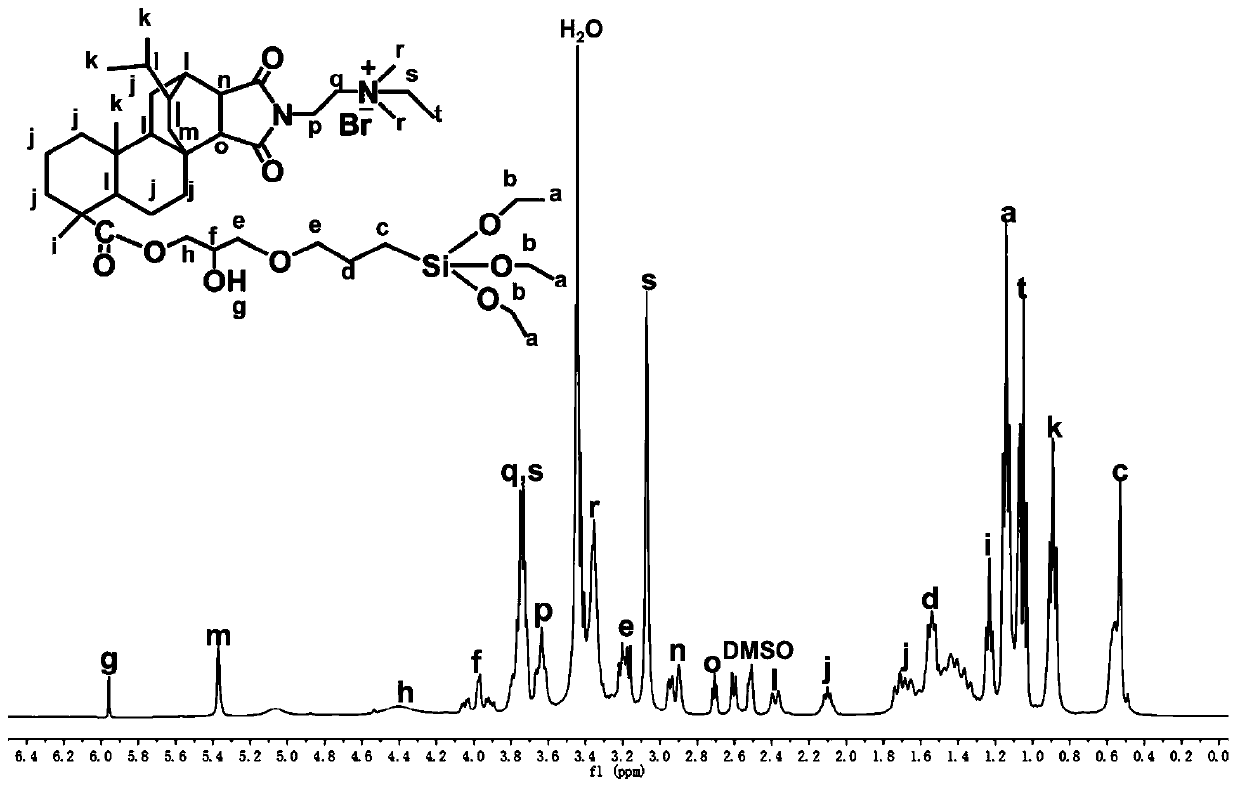

Embodiment 1

[0035] Weigh 50g of rosin (first-grade rosin, Jiangxi Huajin New Material Co., Ltd.) and 14g of maleic anhydride and pour them into a 500mL four-neck flask, then add 200mL of acetic acid and 0.126g of p-toluenesulfonic acid as a catalyst, and heat to 120 ℃ condensed and refluxed, stirred to make it fully react, after reacting for 10h, filtered to obtain the maleopimaric acid compound. Then add 50g of maleopimaric acid and 800mL of ethanol into a 1000mL four-neck flask, heat to 85°C to condense and reflux, add 12mL of N,N-dimethylethylenediamine dropwise, after the dropwise addition, react for 5 hours, and stand for crystallization , After filtration, the rosin-based tertiary amine compound was obtained. Then add 20g of rosin-based tertiary amine compound, 80mL of bromoethane and 500mL of tetrahydrofuran into a 1000mL single-necked flask, heat to 65°C, condense and reflux, stir to make it fully react, and react for 36h, and filter the product to obtain a rosin quaternary ammoni...

Embodiment 2

[0037] The preparation of maleopimaric acid compound refers to Example 1. Add 20g of maleopimaric acid and 500mL of ethanol into a 1000mL four-neck flask, heat to 80°C to condense and reflux, add 8mL of N,N-dimethylethylenediamine dropwise, after the dropwise addition, react for 5h, and stand for crystallization. After filtration, the rosin-based tertiary amine compound was obtained. Add 25g of rosin-based tertiary amine compound, 100mL of bromoethane and 400mL of tetrahydrofuran into a 1000mL single-necked flask, heat to 55°C to condense and reflux, stir to make it fully react, and after 24 hours of reaction, filter the product to obtain a rosin quaternary ammonium compound. Add 3g of rosin quaternary ammonium compound, 1.3g of 3-glycidyloxypropyltriethoxysilane, 0.007g of benzyltriethylammonium chloride and 80mL of ethanol into a 250mL single-necked flask, react at 80°C for 6h, After the reaction was completed, the solvent was removed by rotary evaporation to obtain a rosin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com