Precise weighing funnel for dairy product processing test

A technology for weighing funnels and dairy products, applied in the field of dairy product processing, can solve problems affecting the rigor of experimental results, affecting the accuracy of experimental measurement, and difficult problems in the quality control of dairy products, so as to reduce wall-hanging residues, improve measurement accuracy and The effect of long service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

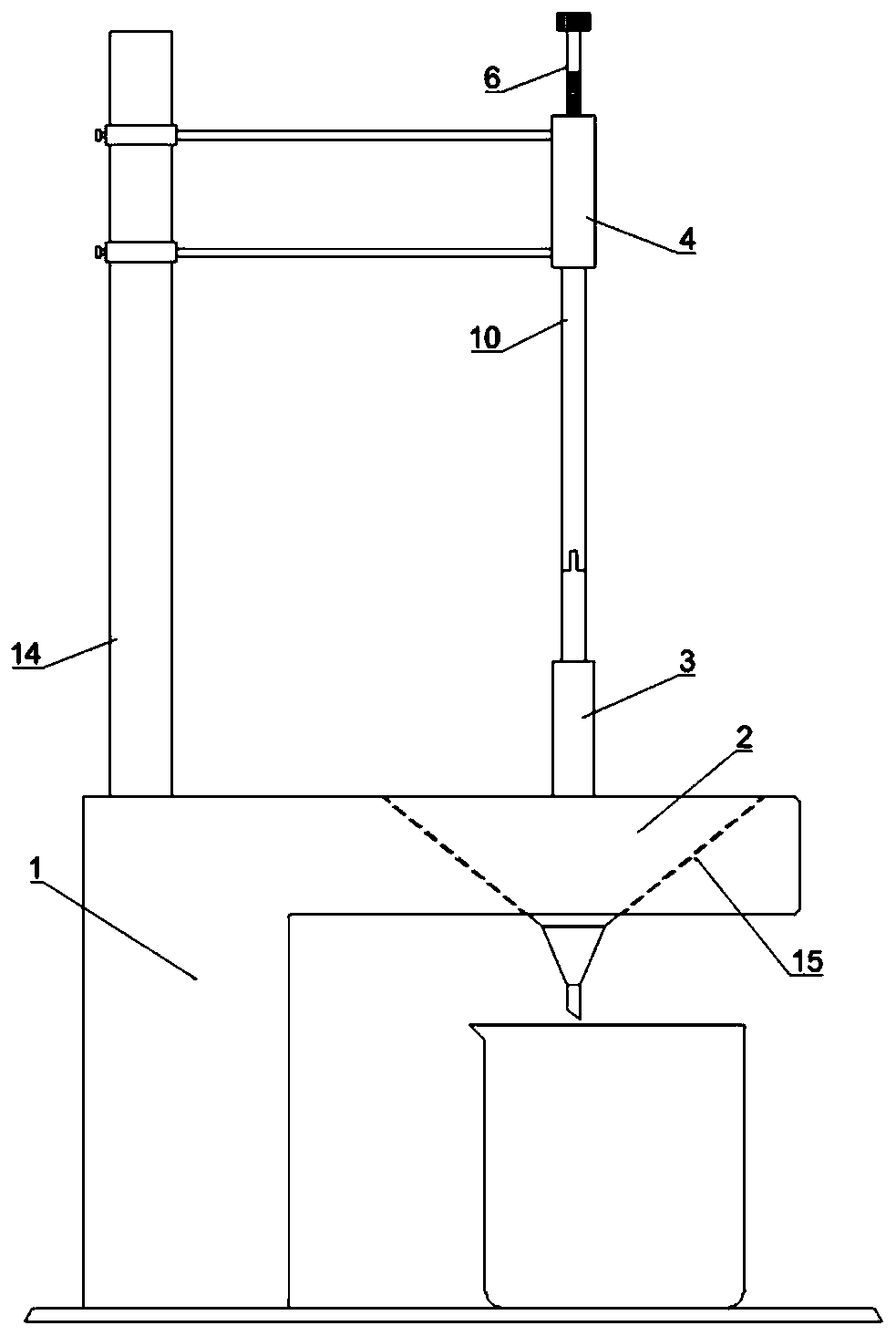

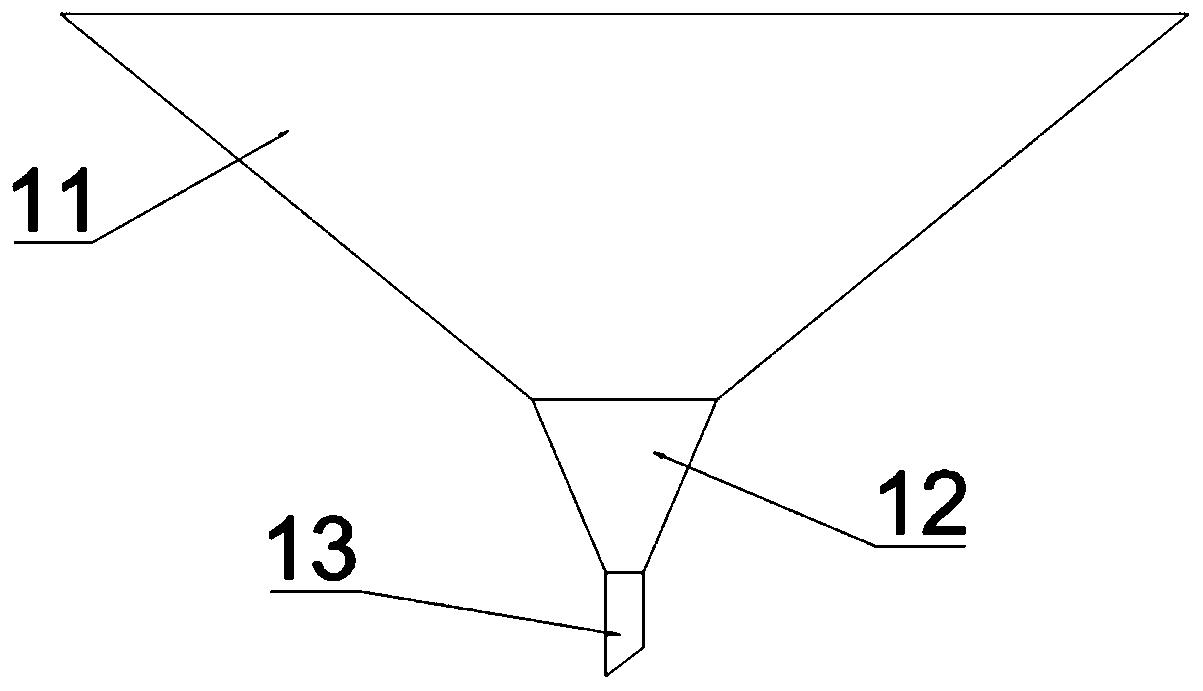

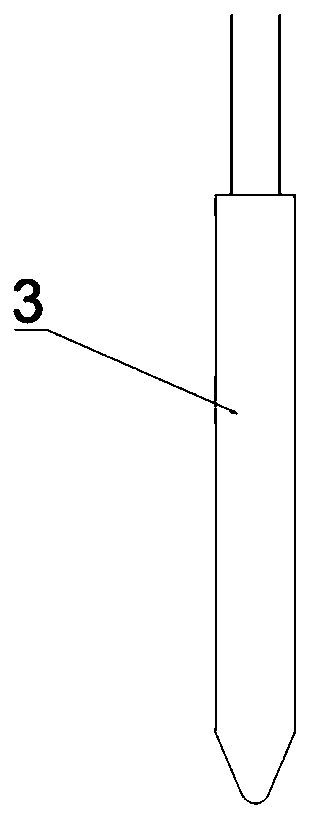

[0017] see Figure 1-4 The precision weighing funnel for dairy products shown includes a support table 1 and a funnel body 2. The support table 1 is provided with a tapered placement hole 15, the funnel body 2 is placed in the placement hole 15, and a column 14 is fixed on the support table 1. The funnel body 2 includes an upper liquid-holding section 11, a middle throttling section 12 and a lower tailpipe 13. Both the liquid-holding section 11 and the throttling section 12 are in the shape of an inverted cone, and the taper of the liquid-holding section 11 is larger than the throttle. The flow section 12 and the tail pipe 13 are uniform hollow tubes, the inner walls of the liquid holding section 11, the throttle section 12 and the tail pipe 13 are provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com