Internal temperature detection device of vulcanizing machine

A detection device and vulcanizing machine technology, which is applied in the field of fluidization equipment and rubber molding, can solve the problems of short service life of temperature measuring resistors, high maintenance intensity of workers, and inaccurate measurement results, so as to achieve low maintenance intensity and avoid steam shock , the effect of accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

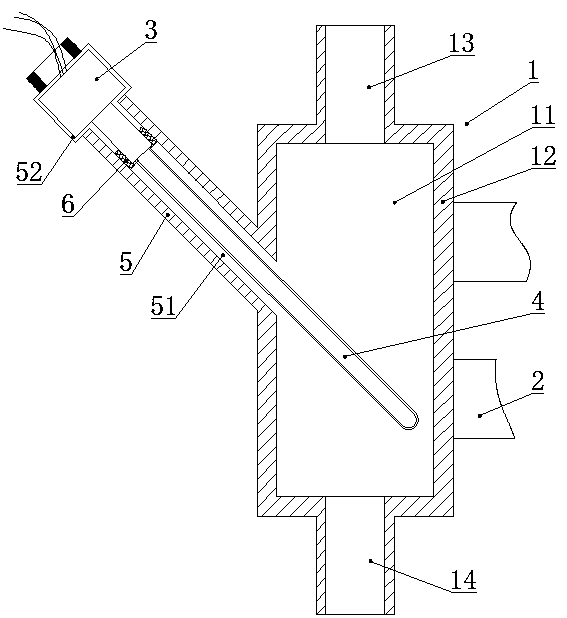

[0013] Such as figure 1 As shown, a vulcanizing machine internal temperature detection device includes a temperature measuring tank 1 , a fixed frame 2 , a temperature measuring resistor 3 and a temperature measuring guide rod 4 .

[0014] exist figure 1 Among them, the temperature measuring tank 1 is vertically fixed on the body under the main machine of the vulcanizing machine (not shown) through the fixing frame 2 . In the present invention, the temperature measuring tank 1 includes a tank body 12 that closes the tank cavity 11, a steam introduction pipe 13 communicating with the tank cavity 11 is provided at the upper end of the tank body 12, and a steam inlet pipe 13 connected with the tank cavity 12 is provided at the lower end of the tank body 12. 11 communicated steam outlet pipe 14.

[0015] One side of the tank body 12 is provided with a support pipe 5, suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com