Mesh belt solid medium isolation structure for shaving board production

The technology of solid medium and isolation structure is applied in the field of mesh belt solid medium isolation structure for particle board production, which can solve the problems of sticking between wood particles and mesh belt, and achieve the effect of compact structure, improving production quality and efficiency, and preventing sticking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

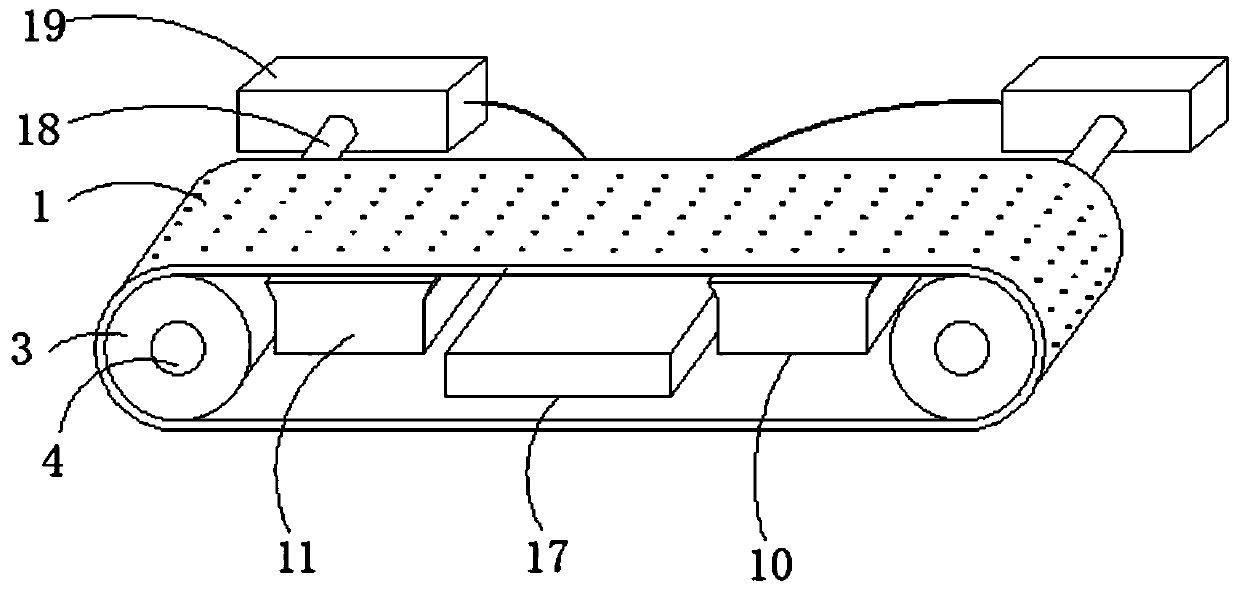

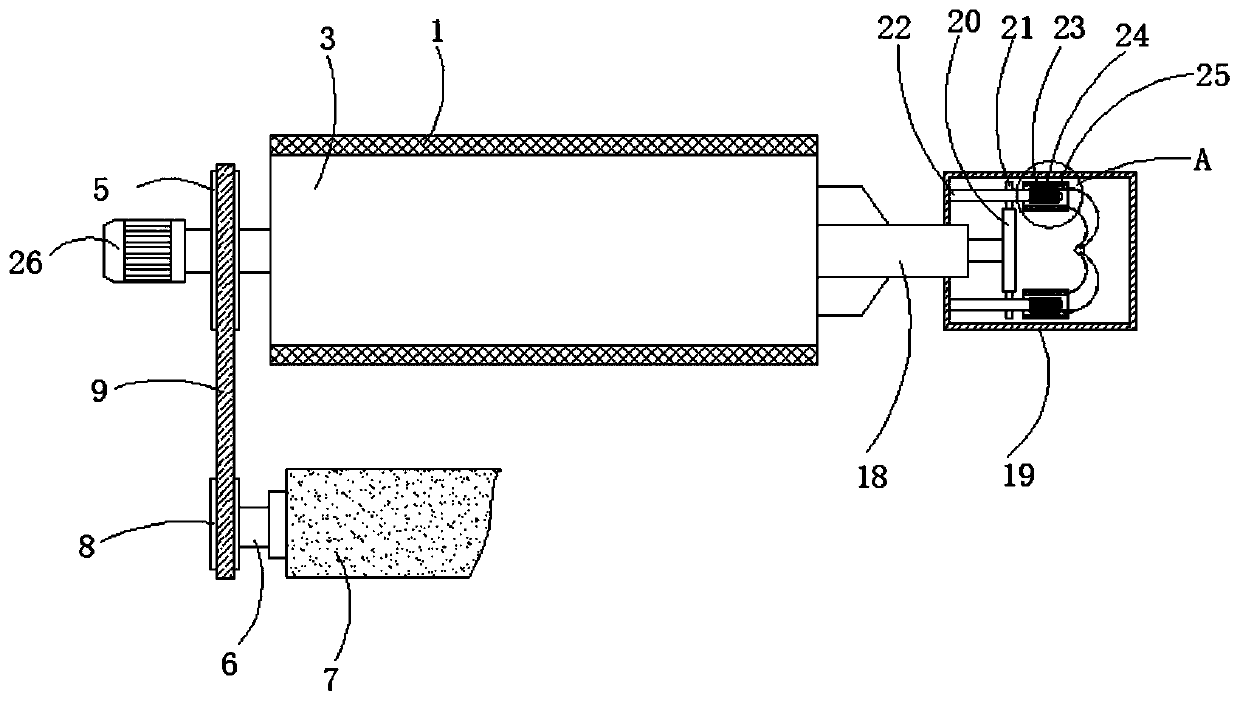

[0028] refer to figure 1 and image 3 , a mesh belt solid medium isolation structure for particleboard production, a layer of kraft paper is laid on the top of the mesh belt 1, and the kraft paper will be used to separate the mesh belt 1 from the raw material of the wood board to prevent the wood board from sticking to the mesh belt 1 during the pressing process. The feeding end of the base 2 below the belt 1 is provided with an auxiliary roller 6, which is rotatably connected to the base 2, and the kraft paper roll 7 can be installed on the auxiliary roller 6, and the kraft paper roll 7 follows the rotation of the auxiliary roller 6 for unwinding.

[0029] Further, one end of the auxiliary roller 6 is provided with a drive assembly, the drive assembly includes a driving pulley 5, a driven pulley 8 and a drive belt 9, and the driven pulley 8 is fixedly sleeved on the extension shaft at one end of the auxiliary roller 6, so The driving pulley 5 is fixedly sleeved on the drive ...

Embodiment 2

[0037] The difference between this embodiment and embodiment 1 is that this embodiment also includes power generation components, refer to Figure 2-6 , the power generating assembly includes a connecting shaft 18, a generating box 19, and a driving gear 20, a driven gear 21, an auxiliary shaft 22, a rotor 23, a fixed cylinder 24 and a stator 25 located inside the generating box 19, and the connecting shaft 18 One end is coaxially fixedly connected to the transmission wheel 3, and the other end of the connecting shaft 18 runs through the power generation box 19 and is fixedly sleeved with a driving gear 20, the driving gear 20 meshes with the driven gear 21, and the driven gears in this embodiment are 4 One, the inside of the power generation box 19 of the driven gear 21 is provided with an auxiliary shaft 22, the auxiliary shaft 22 is rotatably connected with the box wall of the power generation box 19 through a bearing, the driven gear 21 is fixedly sleeved on the auxiliary s...

Embodiment 3

[0042] The difference between this embodiment and embodiment 2 is that this embodiment also includes a booster fan 11, refer to figure 1 and figure 2 , the booster fan 11 is located below the conveying surface of the mesh belt 1 near the discharge end, the booster fan 11 is opposite to the rotation method of the adsorption fan 10, and the booster fan 11 shares a power supply 17 with the adsorption fan 10, The booster blower 11 can blow the kraft paper upwards when the board is discharged, and assist the kraft paper and the board 12 to leave the mesh belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com