Intraosseous fixing screw made of semi-threaded magnesium alloy and magnesium alloy

A technology of fixing screws and magnesium alloys, which is applied in the field of orthopedic instruments, can solve the problems of increased difficulty of use by surgical operators, insufficient holding force of the nail body, and affecting the recovery effect, etc., achieve good biological safety, avoid deformation and fracture, and accelerate healing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

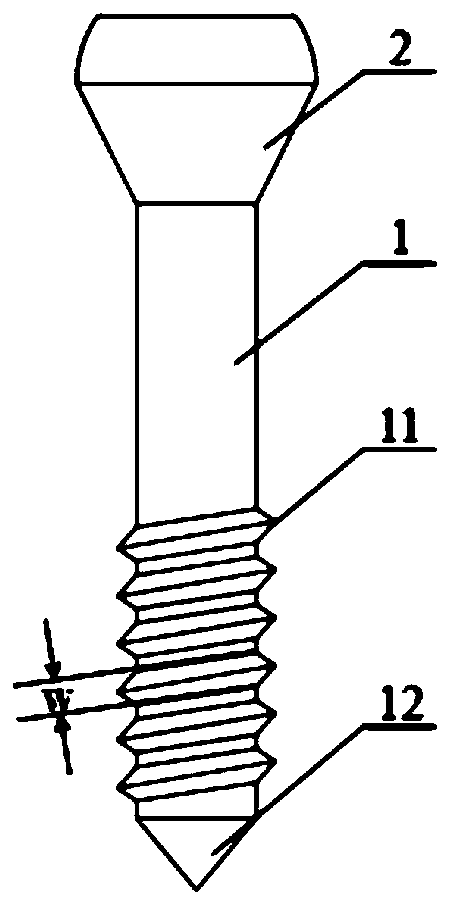

[0052] This embodiment provides a half-threaded magnesium alloy intraosseous fixation screw, such as Figure 8 and Figure 9 As shown, it includes a nail body 1 and a nail cap 2 integrally formed with the nail body 1. The nail body 1 is provided with a thread 11, and the ratio of the length of the thread 11 to the length of the nail body 1 is (0.3-0.5):1. The cap 2 is provided with a molded hole 21, the nail cap 2 is a pressurized nut, and the angle between the conical surface of the pressurized nut and the centerline of the nail body 1 is 20-40°.

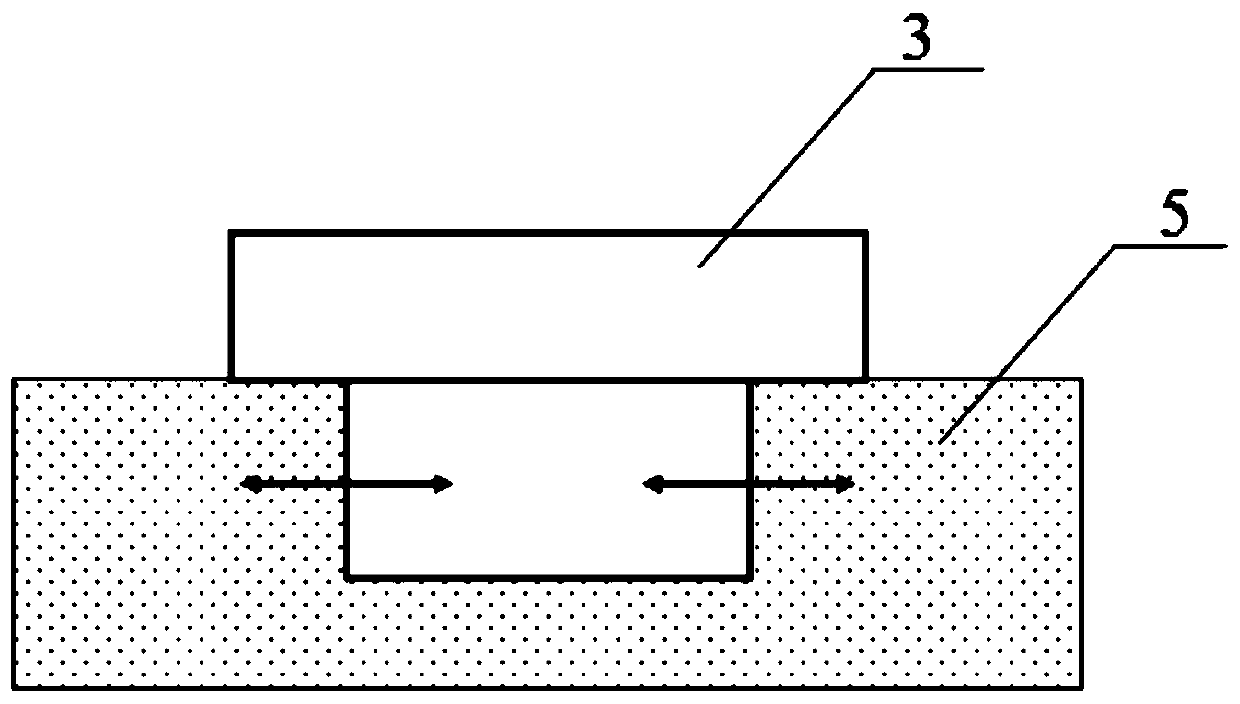

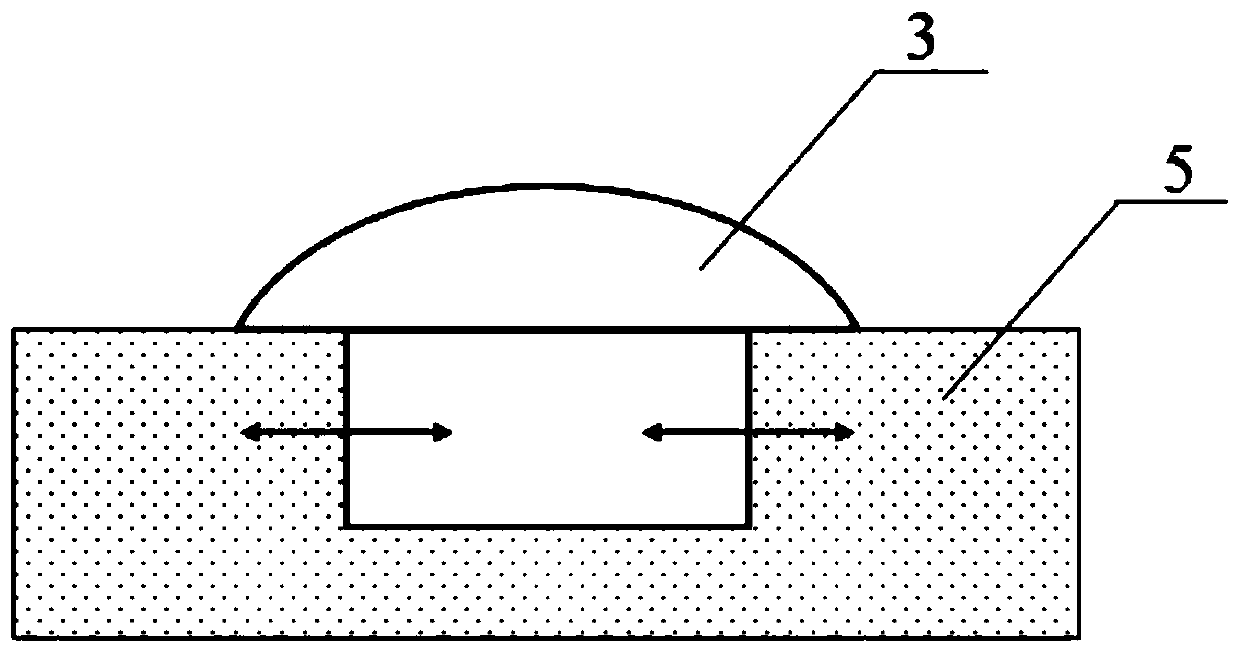

[0053] After the screw is implanted into hard bone such as cortical bone, the pressure screw cap can form a certain angle of pressure on the surrounding bone tissue to embed again through its structural characteristics, which can further strengthen the fixation effect of the screw on the bone block and bone flap. like Figure 10 As shown, 5 of them are bone tissue. The pressurized nail cap is designed with a taper and has an ang...

Embodiment 2

[0063] This embodiment illustrates the working principle of a half-threaded magnesium alloy intraosseous fixation screw.

[0064] like Figure 12 As shown, this embodiment provides a half-thread structure in a half-thread magnesium alloy intraosseous fixation screw, so that the thread 11 is located in the two objects to be fixed, and the holding force of the screw comes from between the thread 11 and the nail cap 2 There is also the holding force of the nail body 1 itself. This design can have a better holding effect on the fixing position with high tension, and can improve the fixing strength of the screw.

[0065] During the use of magnesium alloy screws, it is necessary to use a measuring device to select a screw with a suitable length after drilling, and to expand the hole by tapping to match the thread 11, and then install and use the screw with a surgical tool. Since magnesium alloy screws have low strength and are easily deformed, they do not have self-tapping ability....

Embodiment 3

[0067] This embodiment provides a magnesium alloy for preparing a fully threaded magnesium alloy intraosseous fixation screw, including the following components in mass percentage:

[0068] Nd 0.1~8.0%,

[0069] Zn 0.1~6.0%,

[0070] Ca 0.1~6.0%,

[0071] Zr 0.1~5.0%,

[0072] The balance is Mg,

[0073] In the above magnesium alloy, the total amount of impurity elements is less than 0.05%.

[0074] A half-threaded magnesium alloy intraosseous fixation screw according to an embodiment of the present invention. The magnesium alloy includes high-purity magnesium materials, magnesium-zinc alloys, magnesium-calcium alloys, magnesium-manganese alloys, magnesium-tin alloys, magnesium-lithium alloys, and magnesium-neodymium alloys. alloy, magnesium-yttrium-based alloy, and magnesium-gadolinium-based alloy. Compared with screws made of inert metal materials, the half-threaded magnesium alloy intraosseous fixation screw processed from magnesium alloy in the embodiment of the prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com