New-variety bean product formulation process and extraction method

An extraction method and a technology for soybean products, which are applied to the formulation process and extraction field of new varieties of soybean products, can solve problems such as single variety, and achieve the effects of food safety and harm reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

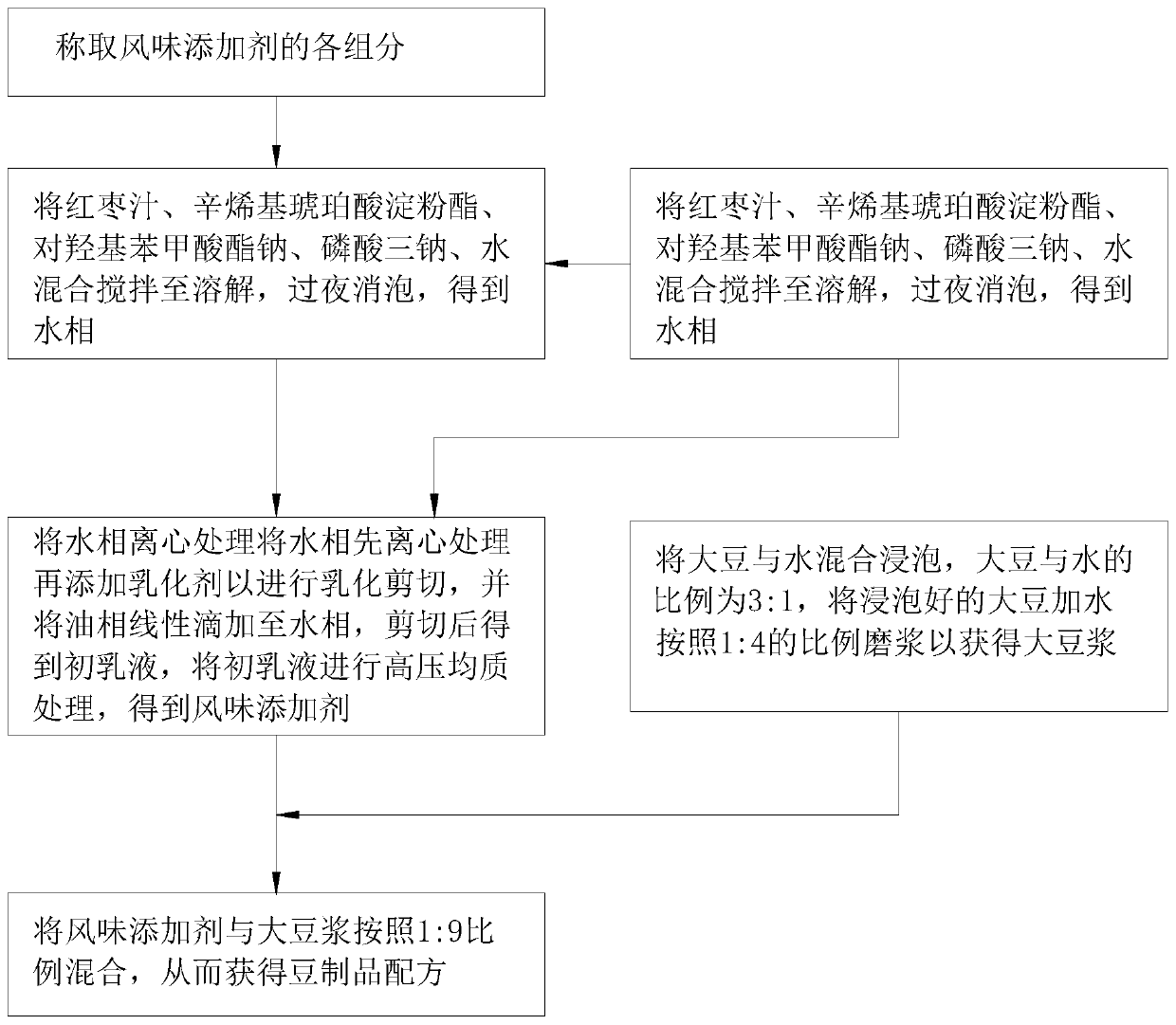

[0049] see figure 1 , the present invention provides a technical solution: a new variety of soybean product formulation process and extraction method, including flavor additives and soybean milk, the ratio of flavor additives to soybean milk is 1:9;

[0050] Flavor additives include anhydrous butter, jujube juice, emulsifier, diacetyl tartaric acid mono-diglycerides, octenyl starch succinate, trisodium phosphate, sodium paraben and water, and the flavor additives The weight percentages of all ingredients are: 12% of anhydrous butter, 7% of jujube juice, 0.2% of emulsifier, 20% of diacetyl tartrate mono-diglyceride, 5% of octenyl succinic acid starch ester, and 0.5% of trisodium phosphate , sodium paraben 0.005, water to make up to 100%. Among them, diacetyl tartrate mono-diglyceride is in liquid state.

[0051] Then make the bean product formula by following steps:

[0052] Step 1: remove the pits from the red dates, crush the jujube pulp with a tissue grinder, add water 6 ...

Embodiment 2

[0060] This example provides a formulation process and extraction method of a new variety of soybean products, including flavor additives and soybean milk, and the ratio of flavor additives to soybean milk is 1:9.

[0061] Flavor additives include anhydrous butter, jujube juice, emulsifier, diacetyl tartaric acid mono-diglycerides, octenyl starch succinate, trisodium phosphate, sodium paraben and water, and the flavor additives The weight percentages of all ingredients are: anhydrous butter 14%, red date juice 10%, emulsifier 0.4%, diacetyl tartrate mono-diglyceride 25%, octenyl succinic acid starch ester 8%, trisodium phosphate 1.5% , sodium paraben 0.008, and water to make up to 100%.

[0062] Then make the bean product formula by following steps:

[0063]Step 1: remove the pits of the red dates, crush the jujube pulp with a tissue grinder, add water 6 times the mass of the pulp, and extract at 80°C for 60 minutes respectively.

[0064] Ultrasonic extraction is performed o...

Embodiment 3

[0071] This example provides a formulation process and extraction method of a new variety of soybean products, including flavor additives and soybean milk, and the ratio of flavor additives to soybean milk is 1:9.

[0072] Flavor additives include anhydrous butter, jujube juice, emulsifier, diacetyl tartaric acid mono-diglycerides, octenyl starch succinate, trisodium phosphate, sodium paraben and water, and the flavor additives The weight percentages of all ingredients are: anhydrous butter 11%, red date juice 10%, emulsifier 0.4%, diacetyl tartrate mono-diglyceride 25%, octenyl succinic acid starch ester 8%, trisodium phosphate 1.5% , sodium paraben 0.008, and water to make up to 100%.

[0073] Then make the bean product formula by following steps:

[0074] Step 1: remove the pits of the red dates, crush the jujube pulp with a tissue grinder, add water 6 times the mass of the pulp, and extract at 80°C for 60 minutes respectively.

[0075] Ultrasonic extraction is performed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com